2022104 The effects of rock fragmentation on the whole size reduction chain from mining to mineral processing are described. The main factors influencing rock

20221026 The effects of grinding conditions on the grinding behavior of rich and poor polymetallic complex ores from two aspects, such as the crushing characteristics of

Download Ore Grinding stock photos. Free or royalty-free photos and images. Use them in commercial designs under lifetime, perpetualworldwide rights. Dreamstime is the

1 Introduction The effectiveness of simultaneous effect of mechanical load and electric field of ultra-high frequency (UHF) in the process of iron ore crushing is substantiated in

OverviewSampling and analysisSamplingAnalysisComminutionCrushingGrindingCrushing/grinding

Some ores occur in nature as mixtures of discrete mineral particles, such as gold in gravel bedIn order to produce a crushed material suitable for use as mill feed (100 percent of the pieces must be less than 10 to 14 millimetres, or 0.4 to 0.6 inch, in diameter), crushing is done in stages. In the primary stage, the devices used are mostly jaw crushers with openings as wide as two mbritannica

2023722 Ore Crushing. Sun Chunbao &. Xu Kuangdi. Living reference work entry. First Online: 22 July 2023. Download reference work entry PDF. Ore crushing is the

20191022 For the first time, the iron ore samples of cubic geometry were tested using a non-uniform volumetric compression unit. Application of the ultrahigh frequency

202198 The ore processing flowsheet includes crushing, grinding to a size of 80% passing –180 μm, the first bulk flotation with regrinding of the flotation tailings to a size of

It is succeeded by comminution in water, arbitrarily called “grinding”. Although a considerable amount of fine grinding is done by dry methods, this book follows usage by

2021815 Abstract. In hard rock mining, blasting is generally the first operation of rock fragmentation from its in-situ state. Therefore, blast design and geotechnical ore

2022217 In spite of this, the output of the blasting directly affects not only the drilling, displacement, and the ore control needed but also the needs and requirements of the crushing and grinding, i.e., mine to mill.

202198 Abstract An analysis of flowsheets for processing sulfide and oxide copper ores, reagent modes, processing equipment, and flotation indicators in some domestic and foreign processing plants and productions is carried out. Autogenous and semiautogenous mills are commonly used in the primary grinding stage in ore processing plants, which

2019108 The ore size reduction process involves two steps: crushing and grinding. The grinding process is the final operation of making the mineral to dissociate from the monomer and making the particle size

2021625 underground mines; the crushing and grinding of ore; the separation of valuable minerals from matrix rock through various concentration steps; and at some operations, the drying, calcining, or pelletizing of concentrates to ease further handling and refining. Figure 11.24-1 is a general flow diagram for

2022123 3.1 Introduction to Crushing and Grinding of Bauxite. The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine. The feed material is crushed or sized so that it is conveyable, as well as correctly dimensioned, for the next step in the process.

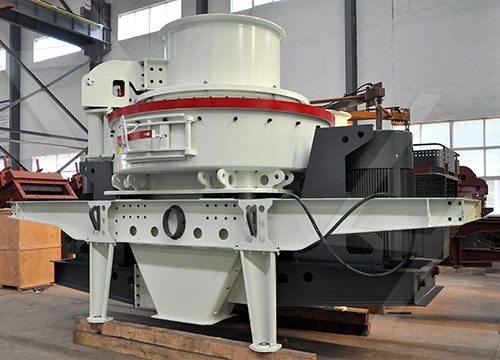

2022519 01 Step #1: Crushing and Screening. The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll crusher for fine crushing. Most medium and small gold processing plants use two-stage closed-circuit crushing, and large-scale processing

202211 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO). This involves multistages of crushing and screening to obtain lump (−31.5 + 6.3 mm) and fines (approximately −6.3 mm) products.

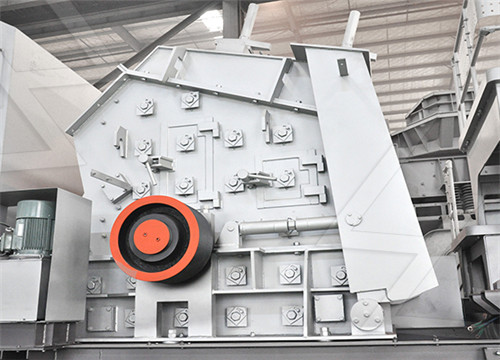

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to 1.5 m. Product: -300mm (for transport) to -200mm (for SAG mill) Feed Rate:

The process of comminution is the crushing and grinding of a material / ore to reduce it to smaller or finer particles. The comminution process reduces particle sizes by breaking, crushing, or grinding of ore, rock, coal, or other materials. The process is most often used in the field of mining and / or mineral processing, where mineral ore is broken down into

202195 Regarding grinding kinetic analysis, it was found that grinding exhibits non-first-order behavior and the reduction rate of each size is time dependent. This experimental work is in line with the Sustainable Development Goal of UN, SDG12: Responsible Consumption and Production and aims to improve the efficiency of ore grinding and thus

202211 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO). This involves multistages of crushing and screening to obtain lump (−31.5 + 6.3 mm) and fines (approximately −6.3 mm) products.

2022617 After ore is mined, it first needs to be crushed and ground to suitable particle size. Semi-autogenous grinding (SAG) mills are widely used, large-scale grinding machines that generate a grinding effect through the impact and abrasion of a small amount of grinding medium and ore clasts of different sizes [].This process can complete the

The process of comminution is the crushing and grinding of a material / ore to reduce it to smaller or finer particles. The comminution process reduces particle sizes by breaking, crushing, or grinding of ore, rock, coal, or

202266 In the grinding process, the two-stage one-closed grinding is an efficient grinding process, which can make the copper ore grind more fully. Among the beneficiation processes, the most successful new processes that have appeared in recent years are mainly mixed flotation processes. Stage 1: crushing and screening

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to 1.5 m. Product: -300mm (for transport) to -200mm (for SAG mill) Feed Rate:

202195 Regarding grinding kinetic analysis, it was found that grinding exhibits non-first-order behavior and the reduction rate of each size is time dependent. This experimental work is in line with the Sustainable Development Goal of UN, SDG12: Responsible Consumption and Production and aims to improve the efficiency of ore grinding and thus

2021815 Run-of-mine ore is usually too large to be useful for construction or metallurgy. Large particles must be reduced to specific sizes to either comply with aggregate sizing regulations, or facilitate mineral liberation; therefore, in the aggregates and mineral processing industries, run-of-mine ore is broken in crushing circuits by cone crushers.

202311 The quality of Indian iron ore resources is generally good with high iron content and high percentage of lumpy ore. More than 85% of the hematite ore reserves are of medium- to high-grade (+62% Fe) and are directly used in blast furnace and in direct-reduced iron (DRI) plants in the form of sized lump ore, agglomerated sinter, and

2016630 Fractal theory, which employs statistical concepts in order to explain particle crushing, may provide a solution to this problem. The particle size distributions are introduced to determine the fractal dimension. The relationship among the particle size, the crushing strength, crushing energy and the probability of survival of the particles are

202291 It enables processing high throughput flows of all particle sizes and is a low-cost, high-value pre-concentration method for all production capacities. Typically, the bulk ore sorting is done after primary crushing on conveyor belt before intermediate stockpiles and further crushing and grinding where ore and waste rock will get mixed (Fig. 2

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين