2023327 This guide will provide a comprehensive overview of the dos and don’ts associated with limestone crushing so you can get the most out of your cone crusher parts. What Is Cone Crushing? Cone crushing

The processing of limestone is mainly crushing, grading and producing quicklime, slaked lime, precipitated calcium carbonate, ultra-fine (nano)

202199 Limestone Mining Process. 2021-09-09. Summary: The output of common limestone crushing sand making production line is 100-200t/h, 200-400t/h, 200-500t/h,

2013118 Limestone, one of the largest produced crushed rock, is a sedimentary rock composed mostly of the mineral calcite and comprising about 15 percent of the

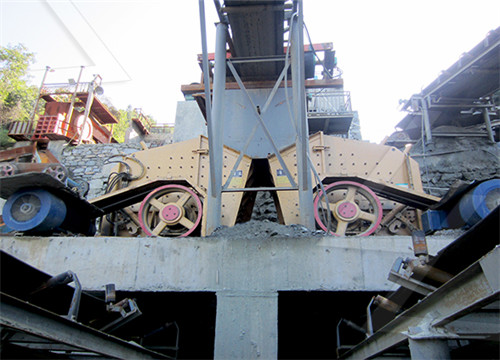

2021111 Crushing-screening plant located nearby the limestone quarry (Adopted from the study of [23]). In general, each limestone quarry has crushing-screening plants

202395 Limestone is the trade name of limestone as mining raw material, it has a very wide distribution with abundant reserves. The main component of limestone is

The limestone crushers and mills are effective for direct-injection of dry sorbent lime or limestone during the CFB process. Below you can explore our catalog of products that can complete a variety of limestone crushing

20211115 Limestone crushing plant is a common stone production line in the sand industry. The commonly used crushing processing machine includes jaw crusher, impact crusher, heavy hammer c, rusher and

3.1. Crushing Capacity The mean crushing capacity and analysis of variance were presented in (Table 1). Analysis of variances clearly indicated that the crushing capacity

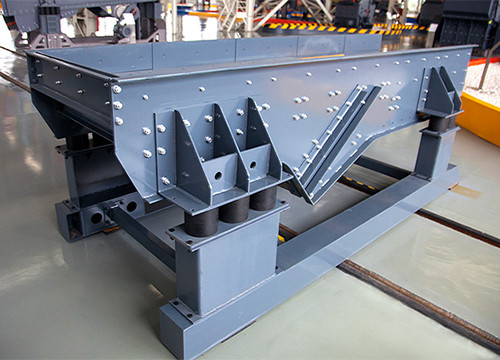

2019114 First stage: primary crushing. Large pieces of limestone are uniformly fed through feeding equipment (such as vibrating feeder) and conveyed to the crushing equipment. Generally, jaw crushers are used

Atorvastatin is the generic name for a widely prescribed statin medication, originally prescribed under the brand name Lipitor. Atorvastatin oral tablet dosage and frequency will depend upon several factors, the most important being the medical condition it is being targeted for and the age of the patient.

20191126 The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’s crushing ratio is smaller. The feed size is usually between 20-30mm and the product size is 0-3mm. Feed. Both

201666 Notably, harder ore often presents itself to the SAG circuit as coarser than softer ore—less comminution is produced in blasting and primary crushing, and therefore the impact on SAG throughput is

201611 Abstract. Using of stones for making the building is the art which is going since stone ages in various forms like caves, pyramids, temples and many more but now a days we are studying about

2021820 1. Tracked mobile cone crushing station. In sandstone aggregate quarry operations, river pebble, granite, lime green rock and other high wear-resistant stones are many. It is recommended to choose a crawler cone mobile crushing station. This mobile crushing station is suitable for crushing sand and iron ore in large-scale ore dressing plants.

2 Crushing Wheels are the more advanced version of the Millstone. It applies Crushing recipes to any items inserted from the direction they are spinning away from. The Crushing Wheel is a high-level device among the Create items. The diagram below shows which items must be built before being able to create a Crushing Wheel. A list of all item

2021820 1. Tracked mobile cone crushing station. In sandstone aggregate quarry operations, river pebble, granite, lime green rock and other high wear-resistant stones are many. It is recommended to choose a crawler cone mobile crushing station. This mobile crushing station is suitable for crushing sand and iron ore in large-scale ore dressing plants.

Stout Trucking delivers a variety of crushed stone, sand, agricultural lime, gravel and specialty landscape and road construction material for commercial and residential use from our strategically located service yard in Greensboro, North Carolina. Aggregates Click to see more > 1/2 inch White Rock.

Crushing capacity= ℎ ˘ˇ ˆ˙˝ ˆ˘ˇ ˆ˛˚ ˝ ˜ ˚ ℎ! where: Ceff=Crushing efficiency Mi=mass of input material Mr=mass of recovered material b a 100 b M M Losses M − = × where: Mb=mass before grinding Ma=mass after grinding 2.2. Sieving Method and Analysis of Lime Powder Sample of 500g was used for conducting sieve analysis

2018221 About 80% of the worlds’ reserves for platinum group metals (PGMs) are in South Africa’s Bushveld Igneous Complex. Processing of PGM involves comminution, flotation, smelting, converting, base

We relocated our recycling facility to 32502 Ortega Hwy, San Juan Capistrano, one mile east of (Gibby Rd.Ortega Hwy.) the old location. Click here for a map to the new facility or call (949) 728-0500 for

Iron ore crushing to size carrettistreet . iron ore crushing plant iron ore crushing plant this circuit division was established to crush the input iron ore from size 400 mm to 100 mm from jaw crusher and 100 mm to 20 mm size in cone crusher and will be used into dri kilns the capacity of circuit is 100 tph it is further crushed into 518mm

2013118 In addition to being used as an industrial material, limestone is used to produce lime. Lime (CaO) is an important manufactured product with many industrial, chemical, and environmental applications. Lime production involves three main processes: stone preparation, calcinations, and hydration. Stone preparation includes crushing

20231027 Limestone coarse crusher: jaw crusher. The limestone jaw crusher is usually used as the first rock crusher, and it is suited for medium-size crushing of ore and bulk materials with a compressive strength of not more than 320Mpa. Jaw crusher is divided into coarse crushing and fine crushing. The feeding size is 125mm~750mm.

2022420 The processing of limestone is mainly to crush, classify and produce quicklime, slaked lime, precipitated calcium carbonate, ultra-fine (nano) calcium carbonate, carbon dioxide, etc. Limestone generally adopts dry crushing process. For limestone used in metallurgy and roads, the ore can be crushed and screened.

The present invention is fit to alumina producer lime and prepares needed limestone crushing process requirement, increases boulder yield to greatest extent, reduces the generation of 0~18mm waste material, has improved the utilization rate of ore, has reduced the waste of limestone resource.Adopt the inventive method crushed product through

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين