201583 Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals. It is done in order to

2017825 With such an approach, up to 70% of the associated metals is lost in the tailings from the ore dressing operations; as a result, the tailings dumps accumulate large

201734 It is a process of ore preparation, milling, and ore dressing or ore beneficiation. Ore dressing is a process of mechanically

2009516 the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiation. Ore dressing is a process of mechanically

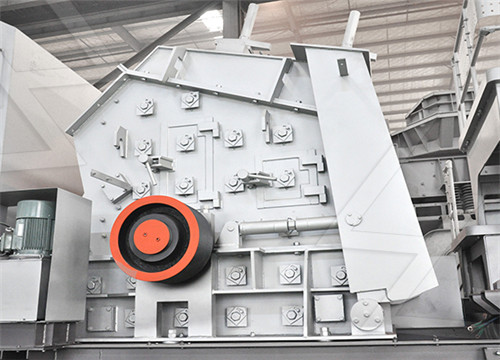

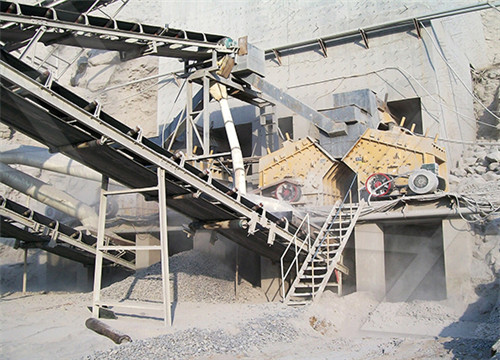

20231018 The fundamental operations of ore-dressing processes are: a) the breaking apart of the associated constituents of the ore by mechanical methods and b) the

202343 Mining, Dressing (Beneficiation), and Mineral Processing Ore mining consists of three major types of operations: mining, dressing, and mineral processing. 40

Published: 13 December 1924 Ore Dressing: Principles and Practice C. H. D. Nature 114,856 ( 1924) Cite this article 535 Accesses Metrics Abstract TEXT-BOOKS of ore

Mineralogy applied to ore dressing is a reliable guide for designing and operating an efficient concentrator. A procedure for conducting mineralogical studies in conjunction with ore

202064 The stone shows a complex organization of the ore dressing that depended on the environment, quality of the ore, habits and investments, and that cannot be

20181119 process is also known as mineral dressing or ore dressing (Clarence H. Lorig, March 2017). During During this operation, mineral doesn’t loose its chemical and physical id entity.

20211122 dressing, ore dressing, mineral extraction, mineral beneficiation, and mineral engineering. These terms are often used interchangeably. 1.1 Ores and Minerals Ore is a term used to describe an aggregate of minerals from which a valuable constituent, especially a metal, can be profitably mined and extracted.

2021124 3.1.1 Group 1 mining and beneficiation as a single stage. Most of the studies considered beneficiation altogether with the mining operation. For example, Awuah-Offei and Adekpedjou carried out a review scrutinising the very first LCAs applied to the mining sector.This work is focused on the extraction stage, and it mentions the

2022312 Well drilling is the process of drilling a hole in the ground for the extraction of a natural resource such as ground water, brine, natural gas, or petroleum, for the injection of a fluid from surface to a subsurface reservoir or for subsurface formations evaluation or monitoring. Drilling for the exploration of the nature of the material

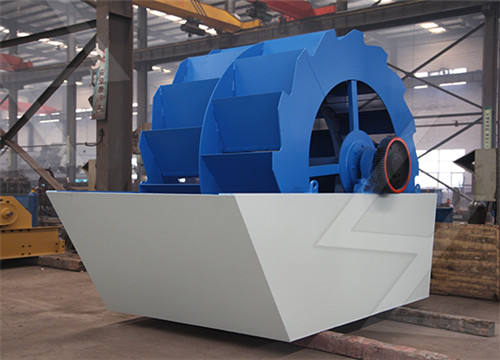

2010630 Wet beneficiation of minerals necessarily requires removal of large amounts of water—typically contaminated—before further processing of the concentrated ores can be carried out.

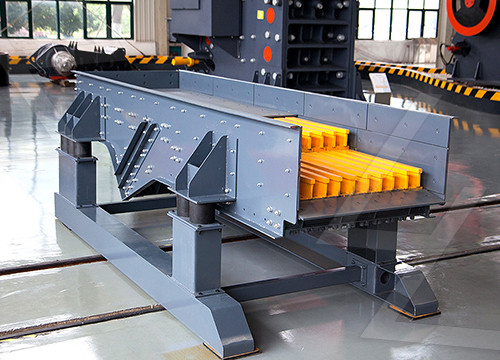

2013315 Crushing Equipments. Grinding Mills. FeedingConveying. ScreeningWashing. Crushing. 1-34-67-910-1213-1516 . Category: Uncategorized. ? passing of samples during grinding in mineral processing. service des mine lafayette ?. Get price and support, find the working site in your country !

2015610 Mineral Processing Laboratory Equipment. Countless installations have proved that operating profits can be increased by installation of a well planned ore dressing laboratory. The basic function of a laboratory is to provide, rapidly, accurate data on metallurgy that can be closely reproduced in the plant.

Pdf Ore Dressing Equipments And Operations. Ore Dressing Division Manual of Procedure for Chemical and Instrumental Analysis of Ores, Minerals, Ore Dressing Products and Environmental Samples Issued by Controller General MOA Main Objects clauses for different types of Companies. I. IT SERVICES, TECHNOLOGY, TRAINING AND

201211 And the four products could be used for different purposes. 720 Zengxiang Lu and Meifeng Cai / Procedia Environmental Sciences 16 ( 2012 ) 715 – 721 jaw crusher dry preparation raw ore dry screening high pressure roller mill crushed ore bin waste rock cone crusher crushed ore bin wet screening +3mm -3mm wet pre-dressing dewatering

2016610 Gravity Concentration equipment includes two Small Laboratory Mineral Jigs, one 4″x 6″ Mineral Jig, and 2 Wilfley Concentrating Table with both sand and slime decks. Flotation includes two “Sub-A” Laboratory 2,000-gram cells, two 500-gram cells, and one 1,000-gram cell. Cyanidation or other solubility test equipment is available to

20201015 Therefore, the reasonable process of placer gold ore dressing should be the joint operation of several gravity dressing equipments. The gold concentrate obtained in the rough beneficiation

2014514 Inefficient, more product is over ground. Used mainly for laboratory testing of ores, making paint mixtures, medicines etc. CONTINUOUS GRINDING. Ore is fed into the mill continuously at a

Mineral processing, also known as ore dressing, mineral beneficiation, or mineral engineering, is defined as the science and art of separating valuable metallic and nonmetallic minerals from unusable gangues. The journey from ROM ore to concentrate and finally metal travels through many operations of liberation, separation, concentration

201733 Particle impact noise detection (PIND) test is a kind of reliability screening technique which is used to detect free particle in hermetical components and is specified in MIL-STD-883E method 2020.7.

20201029 2.2.2 Mineral Dressing With Centrifugal Concentrator Send the gold ore ore larger than 8mm through the conveyor to the compound crusher for crushing. After crushing by crusher, 0-3mm alluvial gold

2019326 TEXT-EOOKS of ore dressing are frequently little more than extracts from makers' catalogues. The volume by Prof. Simons is of a different character. It gives the usual descriptions of plant, but

2020825 popular, particularly in non-coal mining. Gravity can be utilized for ore transportation and broken ore stored within the stope may f unction as a working platform and temporary wall supports. It was quite attractive in the period before mechanization became widespread, when small-scale operations on vein-type deposits prevailed.

201564 In this stone we present some equipment, devices and modern, cutting edge, used worldwide and in our country (in recent years) to determine the physical and mechanical characteristics of soils [1

2018112 In mineral processing, a number of unit operations are required to prepare and classify ores before the valuable constituents can be separated or concentrated and then forwarded on for use or further treatment. The field of mineral processing has also been given other titles such as mineral dressing, ore dressing, mineral extraction, mineral

2017731 Download to read offline. Science. Ores are typically sorted to increase the efficiency of other refining processes, by reducing the amount of material to be processed while simultaneously increasing its purity. This module explains the ore separation processes. Prof. A.Balasubramanian Follow. Professor at University of Mysore. Pramoda

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين