20211112 However, the energy associated with the double impeller impact crusher is much higher and energy intensification, rather than energy efficiency, is the main gain of the double impeller design. The double

Impact Crusher. The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of

2022125 Numerical Simulation of a Single and Double-Rotor Impact Crusher Using Discrete Element Method CC BY 4.0 Authors: Memory Bwalya Cavendish University

2021320 A number of experiments were conducted on a laboratory batch impact crusher to investigate the effects of particle size and impeller speed on grinding rate and

2019531 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to

2002101 In this stone we develop a performance model for impact crushers. The product size distribution is obtained as a function of the crusher’s rotor radius and angular velocity, the feed rate and

2017827 Abstract—In focus are issues of metallurgical slag disintegration in centrifugal impact crushers. The article shows the model of material breaking in the

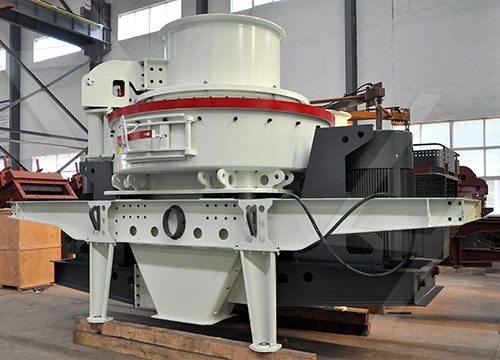

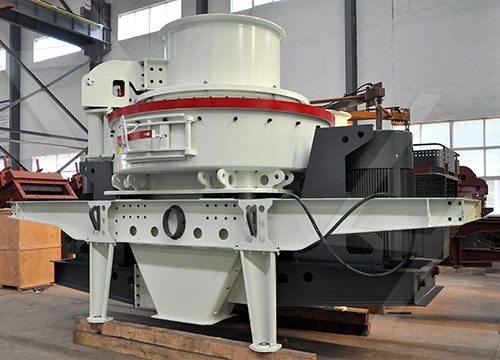

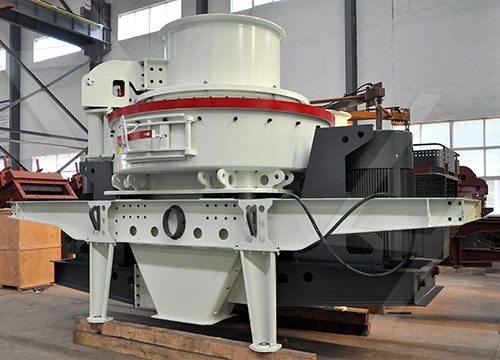

• Introduce the vertical shaft impact crusher (VSI) and how it works. • Describe the need for innovation in the tuning of production in the aggregate sector. 1.1 Aggregates and their

201341 On the empirical design, the impact angle can be far outside of the optimum impact angle of 90°. In this work, the invention is based on providing ring armor impact

2002101 In this stone we develop a performance model for impact crushers. The product size distribution is obtained as a function of the crusher’s rotor radius and

2016210 has to follow these three steps: crusher selection, crusher layout and process design. 2.4 Crushers . A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle. The ore can have a size of up to 400mm. There are many types of crushers but the major ones are the jaw, gyratory and the cone

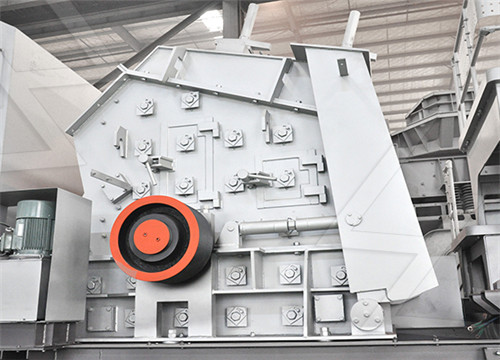

20211112 The impact crusher design and the rendering of its simulated version are shown in Figure 1, with dimensions specified in Table 2. In this , the parameters that were determined for two materials, silica and Dolomite are given in Table 3. The table also includes the threshold energy levels for the particles that are simulated.

2017630 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine

200311 Abstract. Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these costs. Being able to predict the geometry of a worn crusher will help designing the crusher liners for improved performance. A model for prediction of sliding wear was

2023512 It is also well suited for processing materials with a high silica content, such as quartzite, glass. Details you may concern. Capacity: 60-520 t/h HVI sand making machines is also called a high-efficiency vertical shaft impact crusher. Its crushing chamber adopts the best material impact angle design, achieving sand making and shaping.

202276 Impact Crusher, fitted with its third . crushing path, is ideally suited for the crushing of medium-hard rock down to a well graded, very highly cubical, product size of 0 1½ inch. With its unique design, excellent control over the product grading and proven success, the APSM impact crusher is well suited to meet a wide range of

20231026 Impact Crusher; VSI Sand Making Machine; copper, manganese, lead, iron, coltan, chrome, silica sand, and so on. Build a cooperate relationship with mine locate in more than 60 countries, own a good name in the international market, owing to reliable mining machine quality, reasonable processing flow design and satisfying after-service.

Mining Stone Crusher Machine Mobile Impact Crusher. US$5,000.00-45,000.00 / set. 1 set (MOQ Wet Fertilizer Cow Waste Chicken Manure Ore Slag Slime Silica Sand Wood Shavings Sawdust Lignite Coal Sludge Rotary Dryer Drying Machine our plant successfully applied ISO9001: 2015 quality certificate and manage to design 10 to 5, 000

2022123 impact crusher design silica in azerbaijan. Impact Crusher for Hard Chert Processing: Impact crusher is designed for the hard and brittle material. Depending on chert's physical property, impact crusher can be used in the fine crushing stage. mpl impact crusher features a unique combination of heavy rotor design, wear material and crushing

20181226 Material crushed in an impact crusher is an example of dynamic impact. When the material is crushed in an impact crusher, the freely falling When material is somewhat friable and has relatively low silica content. For primary crushing with a reduction ratio of 6 to 1. When a relatively coarse product is desired, top size usually larger than

202255 The most efficient method of controlling dust generated in a crushing plant is the use of dust suppression systems within a methodology and understanding of your process, mechanical stressors, enclosures,

2022216 Molecular Weight: 60.084 g/mol. Exact Mass: 59.966756 g/mol. Boiling Point: 4046°F at 760 mm Hg. Melting Point: 3110°F. Silicon dioxide (SiO2) is a naturally occurring compound of silicon and oxygen. This is the primary compound present in silica sand, which occurs in three main crystalline varieties, including quartz, tridymite, and

2019823 Silicon (Si) is a semi-metallic or metalloid, because it has several of the metallic characteristics. Silicon is never found in its natural state, but rather in combination with oxygen as the silicate ion SiO 44- in

202276 standardized design of the apron liner system helps to further reduce the impactor cost of operation. REAR . APRON. The rear apron (secondary impact zone) is a heavy-duty fabricated component equipped . with 3. ½ inch thick, replaceable bolt-on impact plates of high quality, wear resistant high chrome cast alloy.

2022419 If it is a limestone with high silica content, Symons cone crusher is a better option than impact crusher or heavy hammer crusher. There are several ways for the selection of crushing equipment and design of stone crusher plant, the following factors need to be taken into consideration when making a choice, like hardness of raw materials

2022815 1. Introduction. The sustainable development goals (SDGs) addressed the importance of the buildings and construction sector in the 2030 agenda for sustainable development (Mostert et al., 2020).Concrete is the most consumable material in the World, just behind water, which accounted for 3 tons/year/person (Brooks, 2007).The projected

2022427 5.2 Limestone crushing plant equipment combinations. Limestone Mohs hardness is 4-5, which is very low, and the silica content in the stone is low, too, thus the abrasiveness to the crusher wearing parts is low. It is easier to crush due to the low hardness and brittle, the operational cost will be lower comparing with hard stones.

2022222 Jaw Crushers are configured for primary crushing of even hardest rock. Our Jaw Crushers are crushing without rubbing Minimum dust Oil lubrication, devise having Oil/Grease lubrication system. The company crushers are designed for long life service with minimum maintenance for hard, tough, abrasive material and overload high

The FCB VIF™ crusher is an impact hammer mill equipped with hammers and a non-clogging mobile anvil device. Designed either for primary or secondary crushing stages, it features a high crushing reduction ratio capacity.. Customer benefits: Sturdy design, with a long lifetime and reduced maintenance requirements; Handles sticky and clogging raw

In order to bring the most powerful rock crushers, scalpers and screeners to the most difficult of jobs, we have pioneered revolutionary machines with the highest levels of agility and mobility. You'll boost your productivity with our revolutionary Doublescreen system, our patented Prisec impact chamber and our innovative Hydrocone design.

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين