20201222 Vale Rio Tinto BHP Billiton Fortescue Operating costs Capital costs Tables and charts This report includes 24 images and tables including: 2020 Global total

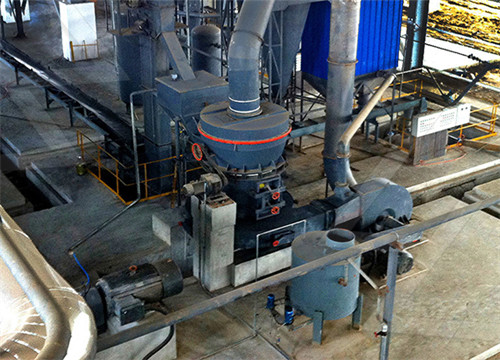

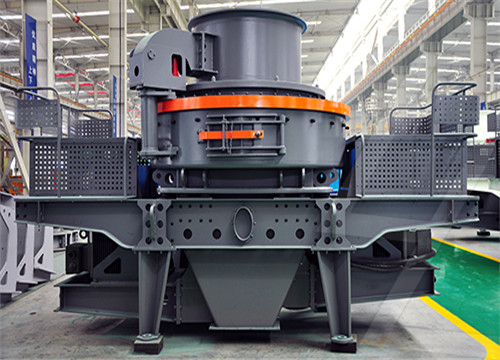

Energy economics. A good rule of thumb is that an integrated mining crushing-grinding plant will have capex costs of $20/Tpa of capacity and consume 20kWh of energy per ton, while total full-cycle costs will run

2022131 $93.85 per ton. Based on reported prices for iron ore fines (62% iron content) imported into China (cost, insurance, and freight into Tianjin Port), the highest

2019111 According to historical data regarding commodity prices from the USGS [29], the price of iron ore was lowest in 1901 (1.71 US$/t) and highest in 2012 with

20231027 105.14. -0.46%. Iron Ore 62% Fe, CFR China (TSI) Swa price information, historical data, charts, stats and more.

201511 The recent unprecedented expansion of the iron ore industry triggered by China's growth and the need for steel for urbanization and infrastructure development

20231018 Release: Primary Commodity Prices Units: U.S. Dollars per Metric Ton, Not Seasonally Adjusted Frequency: Monthly Value represents the benchmark prices which are representative of the global

2022818 The total operating cost of the drilling and blasting, loading and primary crushing phases was 78.81 MUSD/year, and the cost distribution for these phases was 40, 21 and 39%, respectively. In the

2021624 The cost per tonne of product is usually small, typically US$0.50 per tonne concentrate. Assaying costs are those associated with the contractual analysis of the sampled product, and are normally minor. Typical sampling and assaying procedures are discussed in the next section. Marketing costs are those associated with identifying,

201629 METHOD OF CALCULATION. The following calculations have described step-wise capital cost, various operating costs, formulae, specific cost for two systems with graphs, discounted cash flow, cost

202023 For example, the energy intensity of copper mining in Chile increased from 540 MJ of electricity and 3,804 MJ of fuel per tonne of copper in ore in 2001, to 764 MJ of electricity and 8,778 MJ of

Iron Ore increased 4.50 USD/MT or 3.83% since the beginning of 2023, according to trading on a contract for difference (CFD) that tracks the benchmark market for this commodity. Prices for iron ore cargoes with a 63.5% iron ore content for delivery in Tianjin jumped to the $122 per tonne mark in late October, the highest in one month, as

202211 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO). This involves multistages of crushing and screening to obtain lump (−31.5 + 6.3 mm) and fines (approximately −6.3 mm) products.

1 Iron Ore Price: Get all information on the Price of Iron Ore including News, Charts and Realtime Quotes. USD per Ton 10/31/23 03:18 PM Lead: 2,110.40 -2.04: USD per Ton

200911 tonnes and world iron ore production in 2006 was 1690 Mt. accuracy of ±35 per cent. Unit cost breakdowns are presented The principles of particle breakage in crushing and grinding

Iron Ore Price Chart (USD / Metric Ton) for the Last Year. Use this form to dynamically generate charts that show metal prices in the units of your choice and for the specified date range (if available). Simply select a metal and a unit to display the price. Lastly choose the number of days to show in your chart.

20221116 Price per tonne (6-month average) Use in batteries; Lithium carbonate: $82,141: Cathode: Copper: $9,417: Lithium Iron phosphate (LFP) 135 kWh: $13,298: $52,690: 2023 Ford Mustang: Lithium Iron Phosphate (LFP) 70 kWh: $6,895: Mining involves drilling, blasting, and crushing the ore, followed by flotation to separate lithium

2011112 gold bars and three iron ore operations producing concentrates. 2.2.1 Analysis: Overview The objective of the analysis is to provide a detailed inter-facility comparison of the cost per kilotonne mined and processed, split into costs per unit of energy and energy consumed per kilotonne for the following: Open-Pit Mining

20151216 Rules of Thumb in Engineering Practice. Donald R.Woods. Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher. Over 1,000 tph, select a gyratory crusher.

2021728 In 2020, 784.4 million ounces of silver were mined across the world according to Metals Focus. While production is forecasted to increase by ~8% to reach 848.5 million ounces in 2021, it’s still greatly

2013821 In 2010, about 54,000 tonnes of rare earths were produced from bastnäsite in iron ores, 12,000 tonnes from bastnäsite, 11,000 from monazite and xenotime, and 37,000 from ion-adsorption clays, which totaled almost 114,000 tonnes in 2010.7 There is a first group of REMs produced in annual amounts greater than 10,000 tonnes (cerium,

20221020 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic

201988 Therefore, iron ore has become the most popular investment in the eyes of investors. In July 2019, the price of iron ore reached more than US$120 per ton. For the time being, the investment prospect of iron ore is very bright. So what is the global reserves and distribution of iron ore? How much does it cost to build an iron ore processing line?

The first part is called direct economic loss, and the two others are named indirect economic losses. The first part is easily understood, but the other two are often neglected. For example, if mining recovery is 80%, the actual mining cost per ton of mined-out ore will be increased by 25%.

2016524 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice.This also applies to iron ores of the non-magnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين