Pultvizor is one of the leading Jaw Crusher Manufacturers in Dumka Providing Exceptional crushers to all crushing needs. We are committed to quality. Certified: ISO

Manufacturer of Jaw Crusher, Stone Crusher PlantVibrating Screen offered by Hindustan Engineering Industries from Rampur Hat, West Bengal, India.

Martin Kisco Stone Crusher Plant, Sugarcane Crusher PlantSand Crusher Plant Manufacturer from Dumka, Jharkhand, India

Pultvizor is one of the leading 200 TPH Crusher Plants Manufacturers in Dumka, which finds applications in various industries and tasks that involve breaking. Toll Free: 1800-309

20221121 One-piece pitmans Two heavy flywheels to offset pressure peaks in the crusher Crushing jaws made of high-grade aus- tenitic manganese steel, cheek plates

The main fields of application for a jaw crusher include building materials, mineralogy and metallurgy, ceramics and glass, materials science and environmental analysis. They

JAW CRUSHER (UMK) UGURMAK UMK Series Jaw Crushers are the most preferred types of crushers due to their strong design, ability to crush materials of any hardness, low

20231023 Retsch Jaw Crushers are used for the rapid, powerful crushing and pre-crushing of medium-hard, hard, brittle and tough materials. The variety of materials

Jaw Crusher. Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other makes an eccentric movement. There are

Jaw Crushers Price Select 2023 high quality Jaw Crushers Price products in best price from certified Chinese Jaw Crusher Machinery manufacturers, Mining Jaw Crusher

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer

2020814 The Discrete Element Method (DEM) is a numerical method that is able to simulate the mechanical behavior of bulk solids flow using spheres or polyhedral elements, offering a powerful tool for equipment design and optimization through modeling and simulation. The present work uses a Particle Replacement Model (PRM) embedded in

20221121 Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate. The kinematics of this type of toggle system result in a higher capacity than that achieved with a double-toggle jaw

200311 The jaw crusher they used was choke fed with quartzite of size 8–11 mm, resulting in compressive force peaks of 6–13 kN per crushing cycle. Show abstract. The majority of the operating costs of commercial crushing are caused by the power consumption and the wear part maintenance. Better understanding of the variables

2021813 Jaw Crusher In Dumkajaw Crusher. Jaw Crusher In Dumka. Jaw crusher is a trusted for its high quality and good manufacturing jaw crusher which is widely applied to crush high hardness mid hardness and soft rocks and ores such as slag construction materials marble etc jaw crusher is widely used as primary and secondary crushing

\n \n Belt Conveyor Manual area.co.il \n. conveyor belting.We have taken a step by step approach using the methods and procedures proven over.Steel Cord Conveyor Belts.The carcass of SIDERFLEX belts consists in a brass coated steel fabric (see.splicing and repair manual blair rubberlittle david genemcoscrew conveyors isc

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher design characteristics such as width and depth of the crushing chamber, 2.

2020214 Jaw crusher mempunyai keunggulan struktur sederhana, kinerja stabil, perawatan mudah, menghasilkan partikel akhir dan rasio penghancuran tinggi. Jadi jaw crusher merupakan salah satu mesin penghancuran paling penting dalam lini produksi penghancuran batu. Secara umum mesin Crusher dapat digunakan untuk mengurangi

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one another. 4.)

201734 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the

BROCHURE. MESDA is a Chinese manufacturer specializing in producing such mobile material crushing equipment as crawler mobile crusher, jaw mobile crusher, impact mobile crusher, cone mobile crusher, etc. It currently has more than 160,000 square meters of intelligent factory and production lines, can produce more than 3,000 devices a year, has

\n \n Handbook Of Belting Conveyor And Elevator \n. Handbook of conveyor and elevator belting pdf manufacturers factory suppliers from china by 10 years effort we attract prospects by aggressive cost and fantastic provider moreover it really is our truthful and sincerity which assistance us constantly be c,Handbook of belting conveyor and elevator.cema

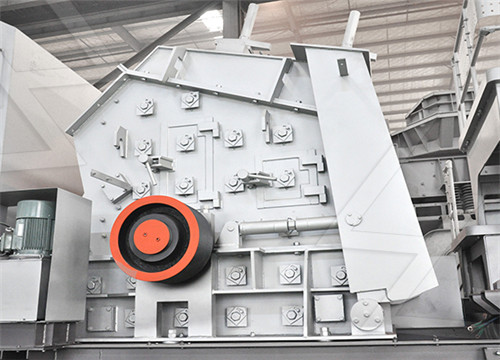

20221229 Fladvad and Onnela [] studied the influence of jaw crusher parameters on the quality of primary crushed aggregates.In the hammer crusher (Figure 2), hammerheads of high wear resistance and strength are attached to the tip of a rotor placed inside a well-sealed, noiseless, and fixed casing.As the hammerheads rotate with a high speed, they

2017630 Moreover, the wear of the jaw liner profile lowers the crusher performance by affecting the shape and the overall size of the crushed particles [12, 13]. Warping and wear of the jaw plate cause a

201529 I believe that through introduction before,everyone on the jaw is no longer strange, application of jaw crush..._jaw crusher blog Jaw crusher base composition and parts configuration 2019-09-22 21:18:09

20181015 C Series™ jaw crusher basic concepts The jaw crusher is a compression type crusher. Feed material is crushed between fixed and movable jaw dies. Large particles are crushed in a single layer, referred to as single-layer crushing. Smaller particles are crushed rock on rock, referred to as multi-layer crushing. C Series™ jaw crusher basic

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width. If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimension.

The jaw crusher MOBICAT MC 110 EVO2 is used for the precrushing of almost all natural rock and in recycling. Compact dimensions, efficient prescreening, simple operation via SPECTIVE as well as impressive production output characterize the efficient key player. Continuous Feed System (CFS) for optimal crusher feeding.

\n \n ethiopia stone crusher stone quarry plant india \n. america stone crushers videos SZM.america stone crushers videos stone quarry plant india.stone crushers machine in méxico,designs all kinds of crushing machine and grinding machine for sale for ago by Guest in Ethiopian Videos 44 Views Used Stone Crusher Supplier In Ethiopia,Various

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين