20221117 The cement manufacturing process mainly includes four steps: resource extraction, raw material preparation, clinker calcination, cement grinding 17,18, and fossil

201913 Clinker grinding technology is the most energy-intensive process in cement manufacturing. Traditionally, it was treated as "low on technology" and "high on energy"

Cement production process with waste utilisation areas. Display full size. In stage one, the essential raw materials-limestone, laterite, bauxite, kaolinite, clay, iron ore, sandstone,

2021419 The methodology described here can be expanded to develop grindability models and perform mixture design optimization of different types of cement to

20141015 As reported earlier, the grinding chemicals have two applications, which are; the modification of the surface charge of particles and the improvement of the

2004111 The electrical energy consumed in cement production is approximately 110 kWh/tonne, and around 40% of this energy is consumed for clinker grinding. There is

The most common grinding systems installed over the last 10 years are VRMs or HRP with ball mill in semi-finish arrangement. The number of VRMs installed for cement grinding

2019215 In this context, three different types of grinding aids were tested at various dosages in a cement plant and the impacts of grinding aids on model parameters of ball

201311 Cement manufacturing process15.3.1. Make-up of Portland cement. Portland cement is a fine powder produced by grinding Portland cement clinker (more than 90%), a limited amount of gypsum (calcium sulphate dehydrate CaSO4.2H2O, which controls the set time) and other minor constituents which can be used to vary the

We first discuss cement production and special nomenclature used by cement industrialists in expressing the composition of their cement products. We reveal different types of cement products, their compositions,

2020128 Besides the aforementioned purposes, Ordinary Portland cement is also used to manufacture grout, wall putty, solid concrete blocks, AAC blocks, and different types of cement. 2. Portland Pozzolana Cement (PPC) To prepared PPC or Portland Pozzolana cement, you need to grind pozzolanic clinker with Portland cement.

Cement is a fine, soft, powdery-type substance, mainly used to bind fine sand and coarse aggregates together in concrete. Cement is a glue, acting as a hydraulic binder, i.e. it hardens when water is added. Everyone knows the word cement, but it is often confused with concrete or mortar. Cement is a key ingredient in both concrete and mortar

2020926 Cement Manufacturing Process. Cement is a material which is used to bind other materials together. Binding means it has an effect of gluing the substances together due to cohesive and adhesive action and then hardens and sets in order to become permanent. Cement is usually not used on its own; it is mixed with other materials called

2020127 6 steps of the cement manufacturing process. When we talked about the manufacturing of cement, anyone who knows the cement manufacturing process slightly will mention “two grinding and one calcination”, they are namely: cement raw material preparation, clinker production, and cement grinding. In the real cement production line,

2019731 Moreover, in the cement industry, various operations like handling of raw material, crushing of limestone, processing in kilns, manufacturing, and storage of clinker, grinding of finished cement

1 Overview on Cement and cement types, its manufacturing process and mineral additives. Looking for cements and cement additives? Cement is a binding that sets, hardens, and adheres to other material to bind them together. Then the Colling process starts. It is cooled with the air, grinding is done to create the cement powder. Gypsum 2

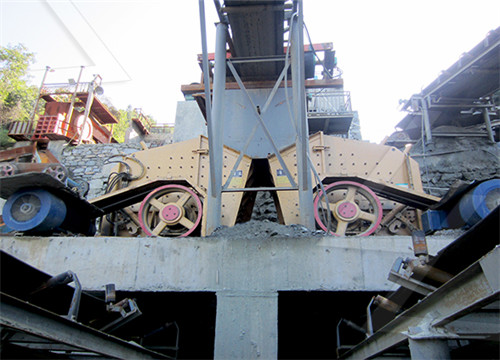

cement ball mill. Application: limestone, clay, coal, feldspar, calcite, talc, iron ore, copper, phosphate, graphite, quartz, slag. Capacity: 0.65-615T/H. The cement ball mill usually can be applied to raw meal grinding or cement grinding. Besides, the cement ball mill also can be used for metallurgical, chemical, electric power, other mining

2019731 Moreover, in the cement industry, various operations like handling of raw material, crushing of limestone, processing in kilns, manufacturing, and storage of clinker, grinding of finished cement

202171 Unveiling Future Tech Innovations. The Jury selected the winners of Indian Cement Review’s “Person of the Year”, “Lifetime Achievement Award” and “Fastest Growing Cement Companies” awardsICR award winners will be felicitated at the 14th Edition of Cement EXPO, India’s leading exhibition for the entire cement industry ecosystem that

20231028 Overview on Cement and cement types, its manufacturing process and mineral additives. Looking for cements and cement additives? Cement is a binding that sets, hardens, and adheres

cement ball mill. Application: limestone, clay, coal, feldspar, calcite, talc, iron ore, copper, phosphate, graphite, quartz, slag. Capacity: 0.65-615T/H. The cement ball mill usually can be applied to raw meal grinding or cement grinding. Besides, the cement ball mill also can be used for metallurgical, chemical, electric power, other mining

2022916 The inclusion of high specific surface materials such as calcined clays in cementitious systems enhances the hydration of clinker products at very early ages, but it may also increase water demand; thus, the pursuit of a flowing concrete may demand an increase in the dosage of superplasticizers. The grinding regime can have a major

201844 unsaturated concrete using different types of cement,” Con- struction and Building Materials,vol. 107, pp. 11–16, 2016. [18] M. Korsch and W. Walther, “Peri-implantitis associated with

2021813 Dual-headed machines are great for quickly producing an aggressive CSP, (Concrete Surface Profile) they are easy to use and cost-effective; and are a common choice for a concrete grinding machine, especially in the rental market. A dual headed machine with the correct diamonds can produce a CSP of 2-3, maybe even a CSP of 4

2019927 Cement mill is another necessary cement equipment of the cement plant. After raw material crushing, cement mill plays vital role in the further cement manufacturing process. Cement ball mill, vertical cement mill, and cement roller press are common types of cement grinding plant. cement ball mill. Cement mill has two functions of the cement

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين