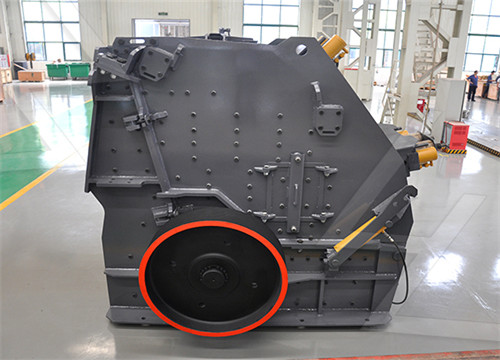

The invention discloses a machine-made sand processing process, which comprises the following processes that stone materials enter a jaw crusher to be decomposed into stone blocks not greater than 350mm, and then, the stone blocks enter a reverse smashing

Province, this stone analyses the supply and demand of local machine-made sand, combined with the application of machine-made sand in highway engineering projects

202396 DB62/T 2917-2018, , Technical specification for the application of machine-made sand concrete, DB62/T 2917-2018

202011 Pradip Sarkar. PDF Based on the investigation of the application of machine-made sand in Shaoxing, Zhejiang Province, this stone analyses the supply and

202141 The gradation and fineness modulus of machine-made sand are important factors affecting the performance of mortar. By studying the influence of different

2020331 Machine-made sand (MS) has become a hot topic in construction materials due to the depletion and scarcity of natural river sand. Aggregate micro fines (AMF) of

2022104 Factors such as technology, equipment, transportation, environmental protection, and type of parent rock should be considered in the production of MS. The

202234 concrete, and proposes a special construction method for machine-made sand self-compacting concrete. 1.Introduction Self-compacting concrete is concrete that

2022513 Orthogonal experiment and grey correlation analysis were used to investigate the performance of machine-made tuff sand concrete. The optimal concrete mix ratio of machine-made sand was obtained by

2023814 , 212013. Mechanical properties of SAP internal curing machine made sand concrete and BP neural network prediction. 1. School of Architectural Engineering, Nantong Institute of Technology, Nantong, Jiangsu 226001, China; 2. Faculty of Civil Engineering and Mechanics, Jiangsu University

2022513 Machine-made sand instead of natural sand has become an inevitable choice for the sustainable development of the concrete industry. Orthogonal experiment and grey correlation analysis were used

202247 2.Jianhong Yang, Huaiying Fang, Sijia Chen, Development of particle size and shape measuring system for machine-made sand, Particulate Science and Technology, 2019, 27(8): 970-976. 3.Jianhong

A novel hydrocyclone sand washer featured by connecting a cylindrical hydrocyclone and a conical-cylindric hydrocyclone in series was developed to improve the poor grading performance in current machine-made sand processing technology. The former hydroycyclone with a flat bottom was designed to enhance the centrifugal intensity,

200941 The mechanical and working properties of the machine-made sand concrete reach the optimum condition when the mineral admixture is 20%, the sand rate is 46%, the stone powder content is 10% and the

2021915 、、。. Abstract: In China, the annual discharge of steel slag, red mud, copper slag, and most ferroalloy slag has reached 10–100 million tons; these slags are difficult to be resued

201751 Section snip Raw materials. Grade 42.5 ordinary silicate cement, crushed limestone in continuous grading 5–31.5 mm, and manufactured sand made of limestone with approximately 0–4.75 mm particle size were used in this test.The stone powder content, in mass of manufactured sand, was adjusted to 5%, 9% and 13%,

2022313 A novel hydrocyclone sand washer featured by connecting a cylindrical hydrocyclone and a conical-cylindric hydrocyclone in series was developed to improve the poor grading performance in current machine-made sand processing technology. The former hydroycyclone with a flat bottom was designed to enhance the centrifugal intensity,

2021716 The quality of machine-made sand, determined by the stone powder content, has a significant impact on the strength, workability, Proceedings of the 2018 25th IEEE International Conference on Image Processing. Athens: IEEE, 2018. 1363–1367. [15]

202283 We can provide complete sets of machine-made sand production lines, quartz sand production lines, construction sand production lines, and sand making equipment, according to different process

2023210 The dissolution process started after the sodium hydroxide solution was introduced to the precursors, and intensity changes in peaks and regions of interest were continuously monitored for up to 24 h. He, Z. Experimental Study on Full-Volume Slag Alkali-Activated Mortars: Air-Cooled Blast Furnace Slag versus Machine-Made Sand as

202396 DB62/T 2917-2018, , Technical specification for the application of machine-made sand concrete, DB62/T 2917-2018、、、、,

Manufactured sand, obtained through mining, mechanical crushing, and processing of rocks has particle sizes less than 4.75 mm. Due to the increasing scarcity of natural sand, there is a growing

202125 Is also used in this study. Machine-made sand (Crushed from limestone) and ACBFS are used as fine aggregate in this study. The density and fineness modulus of machine-made sand is 1495 kg/m 3 and 2.57, respectively. The ACBFS is crushed (Jaw crusher) and screened form air-cooled blast furnace slag aggregate.

202141 [1] Zhu J.L., Lang X.G. and Jia X.E. 2001 Production status and development of machine-made sand[J] Mining and Metallurgy 38-42 Google Scholar [2] Qiu H.Q. 2015 The influence of machine-made sand particle shape and stone powder content on concrete performance[D] (Shenzhen University) Google Scholar [3] Ai C.F., Peng H. and

202328 . SCI (、) One-step synthesis of nanoscale anhydrous calcium sulfate whiskers: direct conversion of calcium carbonate by mixed acid with microemulsion method. 16. . SCI (). Research on mechanical-activated nanoscale bentonite and surface aging behavior of its modified asphalt. 17.

202011 investment, there are some problems in the machine -made. sand produced by the backward pro duction line, such as. poor particle grading (dry method), lack of stone powder. conte nt and excessive

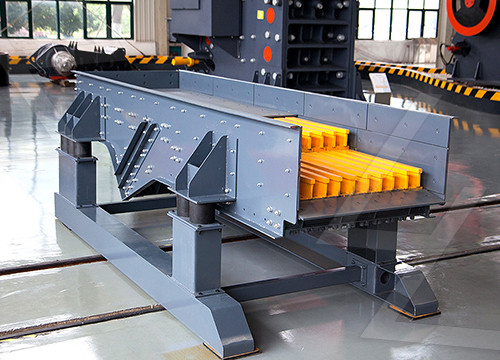

2023421 The wet sand making process has a longer history than the dry sand making process. The stone powder is washed and removed by a sand washing machine (wheel type or spiral type).

2021715 2.2 Test Methods and Specimens. A big difference between pavement concrete and industrial and civil building concrete mix proportion design. For industrial and civil buildings, the concrete mix proportion design follows JGJ 55-201 specification in china for mix proportion design of ordinary concrete, which takes the compressive strength of

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين