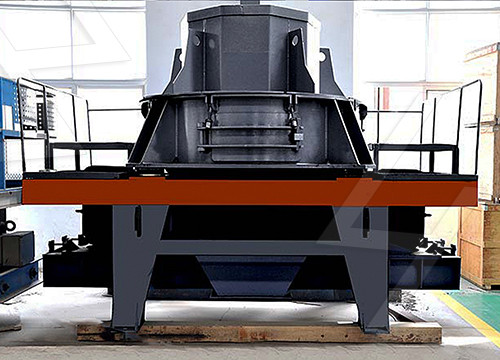

Crushing Operation in Iron Ore BeneficiationCrushing Machinein Iron Ore BeneficiationIron Ore Crusher PricePopular Iron Ore Crusher For Sale

According to different final products applications, varioustypes of crusher equipment are required, such as jaw crusher for primary crushing, impact crusher and hammer crusher for secondary crushing, cone crusher for secondary and tertiary crushing. Iron ore crusher prices are different according to crusher types and production capacities. The VSI

2023331 Iron ore crushing station generally consists of four parts of equipment: feeding equipment, crushing equipment, buffer silo, and unloading equipment. Feeding

As one of the earliest, most widely used metals in the world, iron ore is an important raw material for iron and steel production. At present, iron ore resources are decreasing day

2023109 What are the Types of Iron Ore Crusher Equipment? PricesPictures Natural iron ore through crushing, grinding, magnetic separation, flotation, gravity

For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops.

Iron Ore Crusher,Iron Ore Mining Equipment,Iron Ore Crushing Line. Iron ore crusher equipment manufacturer, liming supply complete iron ore crushing plant, mobile iron

2023925 Output size: 10-350mm Application: river pebbles, marble, calcite, limestone, basalt, quartz stone, etc. cone crusher Types: GP, Hp, Symons crusher Capacity: 1-1200 t/h Feeding size: <500mm Application:

2022818 The primary crushers are four mobile roller crushers (PF 200–9500) with the feed size between 0.80 m to 1.20 m and a maximum product size of 0.35 m; the crushed ore is transported through a system

202211 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for

2023527 Shaking table, also called gold recovery table or gold separation table, is the best fine gold recovery equipment. It can process both gold ore in quartz rock, gold stones, and placer gold. The feeding particle size range of the shaking table is generally between 3mm-0.019mm. The gold beneficiation is stable and reliable, and the distribution

Abstract. The unit operation of the size reduction or comminution of solids by crushers and mills is a very important industrial operation involving many aspects of powder technology. It is estimated that mechanical size

The Ally to Your Iron Ore Processing Plant. Here at Benetech, we dedicate our greatest resources to resolving your daily challenges in bulk material handling. To discuss how you can reinforce a safer, more productive iron ore facility, contact us at (630) 844-1300 to speak with a specialist. Posted in Dust Control.

2023217 Here are some common types of equipment used in iron ore crushing: 1. Jaw Crusher: This is a primary crusher that is used for coarse crushing. It has a fixed jaw plate and a movable jaw plate, and

Iron ore processing by Rio Tinto in the Pilbara region of Western Australia does not involve any chemical treatment. Flowsheets for the Brockman 2 and Paraburdoo processing plants are given in Figures 8.4 and 8.5 (Kinnel, 2013). The flowsheets are relatively simple. Dry processing involves up to three crushing circuits to produce lump and fines.

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to 1.5 m. Product: -300mm (for transport) to -200mm (for SAG mill) Feed Rate:

2023324 The raw ore crushing process is the initial stage of mineral processing, which involves breaking the raw ore into smaller pieces in order to extract valuable minerals. This process may vary

20151226 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks. In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wear-resistant plate

2018101 Depending on the ore characteristics, some ores are suited to HRC (high pressure grinding), which is a much more energy-efficient process, or three/four-stage crushing.

201511 DSO passes through a simple crushing, screening, and blending process (beneficiation) before it is shipped for steel production. DSOs, when mined, typically have iron (Fe) content of between 56% and 64% Fe. By comparison, magnetite ore typically has a much lower iron content of between 25% and 40% Fe and in this form is unsuitable for

202398 The iron-ore bearing rock is first blasted and dug up from open pit mines. The ores from the major mines in Western Australia's Pilbara region are hauled from working faces to crushing and screening

2019114 Iron (Fe) is a metallic element that constitutes 5.6% by weight of the Earth's crust and is the fourth most abundant element in the crust. Iron ores are rocks from which metallic iron can be economically

202374 Iron ore makes up a large part of the mining industry in Australia. Currently, iron ore mining is Australia’s largest source of export revenue at a whopping $63 billion in 2017 alone. Western Australia is the country’s biggest producer of iron ore, with the industry generating over $5 billion in royalties for their state government (depending on the

20221020 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic

2013421 Vibrating feeder is the machine used to feed iron ore evenly to iron ore crushing and grinding machine in iron ore processing plant. Iron Wikipedia, the free encyclopedia In 1783 he patented the puddling process for refining iron ore.

2013315 Gold Ore Crusher description: Gold is usually found associated with the mineral quartz. It is sometimes connected with other minerals too, including iron and

200911 The design outcome is a process flowsheet that specifies the required equipment and their arrangements in the beneficiation plant. The iron ore beneficiation plants normally include a series

201734 The process Comminution involves size reduction and size-wise classification called as screening/ separation. Milling is one of the most important industrial processes. The electric power

2020824 According to the traditional iron ore processing process, the jaw crusher is used for rough crushing, and the ore is subjected to primary rolling from large pieces to small pieces. The counter-attack crusher performs the second crushing, and finally the cone crusher controls the size of the ore particles. Minimize the loss of the crusher.

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين