20201225 The discovery of a world-class tungsten and molybdenum ore deposit from deep exploration in the Luanchuan molybdenum ore concentration area, Henan Province[J]. Geology in China,47(6): 1934-1936. doi: 10.12029/gc

HE Yuliang, HANG Jiangwei, YUN Hui, HU Honglei. The discovery of a world-class tungsten and molybdenum ore deposit from deep exploration in the Luanchuan molybdenum ore

2019101 With the progressive exhaustion of wolframite ore in last several decades, scheelite, sometimes mixed with wolframite, is the chief raw material to extract tungsten (

2023219 This chapter summarizes the status quo of process mineralogy of tungsten and its associated elements in China, focusing on the process mineralogy studies on

2023510 Abstract. Deep separation of tungsten from molybdenum has become a bottleneck in molybdenum metallurgy, especially in high-chloride aqueous systems,

Abstract. The separation of molybdenum (Mo) from tungstate solution is a bottleneck problem in tungsten (W) metallurgy, and it hinders the development of high-purity

This chapter summarizes the status quo of process mineralogy of tungsten and its associated elements in China, focusing on the process mineralogy studies on major

2019101 The current commercial tungsten extractive metallurgy by soda/caustic soda digestion with solvent extraction or ion exchange step can use various raw

201799 A solvent-extraction process for deep separation of molybdenum from an acidic high-phosphate tungsten solution was developed using tributyl phosphate (TBP)

2022129 Early Yanshanian metallogenesis of the Banjing tungsten deposit in Ganxian, Jiangxi province, China: Constraints from geochemistry, Sr–Nd isotopes, zircon

2023219 The chemical composition of several ores is given in Table 1. Tungsten ore associated with molybdenum (referred as “tungsten–molybdenum associated ore” in this chapter) can be divided into porphyry, porphyry, and skarn transition and skarn in accordance with ore genesis. In terms of chemical composition, the valuable metals are

2021415 Tungsten is recognized as a critical metal due to its unique properties, economic importance, and limited sources of supply. It has wide applications where hardness, high density, high wear, and high

2017710 With most high-quality tungsten ores being exhausted, the enhancement of low-grade scheelite concentrates processing has attracted a great deal of attention. The objective of this study is to develop a method to maximize the recovery tungsten and molybdenum from a low-grade scheelite via a new acid leaching process followed by

2023730 Operating molybdenum and tungsten mine in China. CMOC is one of the top five molybdenum producers and one of the largest tungsten producers in the world, focusing on mining, beneficiation, smelting and deep processing of molybdenum and tungsten and related scientific research. It boasts a business system that integrates

Recently, tungsten has drawn worldwide attention considering its high supply risk and economic importance in the modern society. Skarns represent one of the most important types of tungsten deposits in terms of reserves. They contain fine-grained scheelite (CaWO4) associated with complex gangue minerals, i.e., minerals that display similar

20231025 It is also the largest tungsten powder, tungsten carbide powder manufacturer and exporter in China. Tungsten and molybdenum wire sales account for over 60% in China. Company's sales network covers Asia, Europe and America. Exports of related products accounts for more than 35% of China. Headquarters. Kejingshe

In the aqueous system of W–Mo–H 2 O, most tungsten and molybdenum are exit in the form of polymeric anions, and the two exist in very similar forms, which makes their separation difficult. However, in the W–Mo–S–H 2 O aqueous system, molybdenum will preferentially combine with sulfur to form Mo–S polymer ions, and W will still exist in the form of W–O

Tungsten and molybdenum reserves at Sisson. The Sisson mine is estimated to hold approximately 334Mt of proven and probable ore reserves grading 0.066% tungsten and 0.021% molybdenum, containing approximately 22.2 million mtu of tungsten trioxide (WO 3) and 154.8Mlbs of molybdenum. Mining and ore processing

2020827 In this study, a selective separation of tungsten W (VI) from a mixed salt solution was done through a liquid-membrane technology. The transport of W (VI) across the supported liquid membrane was also applied on real sample. Tertiary amine (Tri-n-dodecylamine) was used as an organic carrier and a supported liquid membrane of

202111 At present, processing of tungsten ore with high Mo (Fig. 1) generally requires a pretreatment to reduce the Mo content in crude APT to <3.0–5.0 g/L (the lower limit of Mo content depends on the W recovery method), because a high Mo content means large amount of vulcanizing reagent consumption (Zhang et al., 2016) and wastes

Tungsten and molybdenum reserves at Sisson. The Sisson mine is estimated to hold approximately 334Mt of proven and probable ore reserves grading 0.066% tungsten and 0.021% molybdenum, containing

2020827 In this study, a selective separation of tungsten W (VI) from a mixed salt solution was done through a liquid-membrane technology. The transport of W (VI) across the supported liquid membrane was also applied on real sample. Tertiary amine (Tri-n-dodecylamine) was used as an organic carrier and a supported liquid membrane of

20211115 The formation temperature of cassiterite in tin ore deposits is commonly in the range of 300–500°C as noted in the first summary study on fluid inclusions by Little (1960) and later confirmed by numerous investigations summarized in Naumov et al. (2011) and Bodnar et al. (2014).

2022221 We studied the consequences of the long-term impact of remediated tailing ponds from the Tyrnyauz tungsten–molybdenum mining and processing factory on the environmental pollution and children living in the area. For more than 60 years, the factory has been engaged in the development of tungsten–molybdenum deposits by open-pit

202367 Tungsten Ore Reserves, Mineral Resources, production, and reserve and resource life at operating mines, 2018. No. of Operating Mines 1 Tungsten Mining commenced a prefeasibility study for mining and processing tungsten and molybdenum at the Mount Mulgine Project. 33 The company commenced resource definition drilling in

2020630 The discovery of a world-class tungsten and molybdenum ore deposit from deep exploration in the Luanchuan molybdenum ore concentration area, Henan Province HEYuliang 1,2, HANG Jiangwei ,YUN Hui,HU Honglei (1.

202222 Molybdenum is one of the essential trace elements for the survival of plants and animals, and it is also an important strategic resource in the development of the national economy [1, 2].However, in the mining and metallurgical processing of Mo minerals, there is a large amount of ultra-low concentration Mo-containing wastewater, which is difficult to

2021121 The Sandaozhuang deposit, contains a resource of 0.75 Mt Mo grading average 0.109% Mo, and 0.55 Mt W grading average 0.112% WO 3, and is the largest W-Mo deposit in the southern margin of NCC.In addition, it is the largest Mo and third largest W skarn deposit in China (Chang et al., 2019).Scheelite with various Mo contents coexists

2021629 The incomplete statistics indicate about 96 kt of tungsten content in those deposits, with an average grade of 0.1% WO3 (versus typical grades of 0.3–1% in primary deposits). This stone aims to

2022131 mineral reserves and resources. The project would be the only niobium mine and primary niobium-processing facility in the United States, with construction to begin after financing was obtained. Brazil continued to be the world's leading niobium producer with approximately 88% of global production, followed by Canada with about 10%.

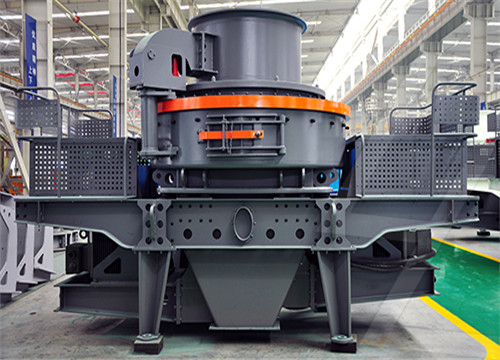

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين