20221228 The following is a list of the equipment and resources you will need to start an extraction and processing business of manganese from manganese ore: A source of manganese ore A...

202139 CEO Martin Kepman It’s imperative to understand the importance of ethically sourced, high purity Manganese and the

202011 Statistics of manganese resources in southern China (data sources: Ministry of Land and Resources, unpublished data): a) histogram showing the proportion of

2019510 Collecting historical data on manganese ore in China over the past 20 years, we identified and evaluated risks during the whole process of production, supply, consumption, reserves, and trade of

201111 Last Updated: 04 May 2023. PDF Hydrometallurgy is the most suitable extractive technique for the extraction and purification of manganese as compared to all other techniques Find, read and

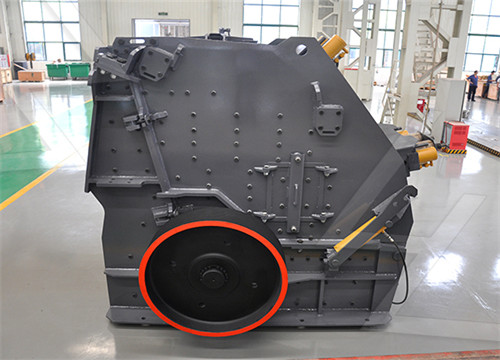

2021330 Currently, local enterprises use carbonate manganese ore as raw material: the coarse jaw crusher is broken after reaching a certain size of fragment, after breaking the fine grain of manganese carbonate

2019115 In general, the commercial grade of manganese ores for Mn alloys production requires Mn > 30% and Mn/Fe mass ratio > 5 ( Tan et al., 2004 ). Many

20221223 According to the publisher's analysis, from January to October 2022, China imported 24.8583 million tons of manganese ore, down 2.77% year-on-year, and the import value was US$4.911 billion, up 19

201651 Abstract. The recovery of manganese metal from manganese carbonate precipitate by leaching–purification–electrowinning was studied. The manganese carbonate precipitate from Baja Mining Corp.'s El Boleo project was readily leached into acidic ammonium sulfate solution. The manganese extraction reached 99.7%. The manganese

2023917 Welcome to. MOIL. MOIL is a Schedule “A” Miniratna Category-I Company. It was originally incorporated as Manganese Ore (India) Limited in the year 1962. Subsequently, name of the Company was changed from Manganese Ore (India) Limited to MOIL Limited during the financial year 2010-11. MOIL was originally set up i.

2014126 1.1. Manganese Ore Deposits Over 80% of the known world, manganese resources are found in South Africa and Ukraine. Other important manganese deposits are in China, Australia, Brazil, Gabon, India and Mexico. The economically mineable manganese deposits are in natural concentrations of 150 500 times the average crustal abundance- .

2022811 range of the general manganese ores and concentrates (about 15–60%). Also, each sample has its distinct content of minor and trace elements, to prove that the optimized analytical method is free from ionic interference. Experimental procedures Because some manganese ore and concentrate types are very hygroscopic in nature,

Ferroalloys Processing Equipment. Isobel Mc Dougall, in Handbook of Ferroalloys, 2013. 4.2.2 Sintering of Manganese Ore. The sintering process employed for manganese ore and the siliceous ores used to produce silicomanganese results in partial reduction of MnO 2, Mn 2 O 3, and Mn 3 O 4 in the ore to MnO by reaction with carbon in addition to

2009515 Overview and role of the EITI. Burkina Faso is rich in mineral resources, and produces gold, zinc, copper, manganese, phosphate, and limestone in substantial quantities. It also has reserves of diamonds, bauxite, nickel and vanadium, however these remain largely unexploited. While the extractive sector accounted for only 8% of

2022315 The grade of manganese in sample is 14.53%, which is much lower than the content of high-grade manganese ores. On the other hand, the contents of Mn/Fe and P/Mn are 9.02% and 0.0045%, respectively; and the alkaline coefficient of sample is 2.26. The main gangue component is CaO, followed by SiO 2, MgO, Al 2 O 3, etc.

Deep-sea mining is an emergent industry targeting three main resources of interest: manganese nodules, seafloor massive sulfides and cobalt crusts. Interest in deep-sea minerals exists within the national jurisdictions of coastal States and in Areas Beyond National Jurisdiction (ABNJ). Within ABNJ, the International Seabed Authority (ISA) is

2019228 Abstract and Figures. This stone presents an optimization methodology for the geometric configuration of a room–and–pillar mining project, considering safety and operational restrictions while

2023423 Manganese is a chemical element with the symbol Mn and atomic number 25. It is a hard, brittle, silvery-gray metal that is commonly found in the Earth's crust. Manganese is an essential trace element that

201093 The charge for silicomangansese production consists of manganese ore (often mixed with ferromanganese slag) dolomite or calcite, quartz, and in some cases, other additions. These materials have different melting properties, which have a strong effect on reduction and smelting reactions in the production of a silicomanganese alloy. This article

2023628 Manganese is an important raw material used in the smelting of iron ore and in the production of ferroalloys. Manganese deposits can be found in nearly every geological formation. It is, however,

2012314 manganese ore used in this study are given in Table II and Figure 1, respectively. The original ore is of low manganese content (36.6 wt pct) and low Mn/Fe ratio (2.8). For the production of ferromanganese alloy, it was reported by Kothari and Nilkantha[3] that the Mn/ Fe ratio in manganese ore should be at least 5:1. As

2016512 In this study, a method for preparing pure manganese sulfate from low-grade ores with a granule mean size of 0.47 mm by direct acid leaching was developed. The effects of the types of leaching agents, sulfuric acid concentration, reaction temperature, and agitation rate on the leaching efficiency of manganese were investigated. We observed

2019115 Washing is the initial procedure to remove clay minerals from Fe-Mn ores and provides preconditions for the smooth conduct of subsequent processing operations (Ding et al., 2013, Tripathy et al., 2015). The low- and high-Al manganese ore fines were compared, and the results suggest that the high-Al manganese ore fines (1.70 wt% Al 2

2021131 Magnetic separation is often considered pertinent for manganese ore beneficiation when the ore is abundant with siliceous rich gangue mineral phases. However, the process is deemed to be inapposite for the ferruginous type of ore, and remains a grey area of research. In the present investigation, two different types of manganese ore were

2022110 The smelting reduction of manganese ore in the converter has been reported in China since the 1990s, and some steel enterprises have successively carried out industrial tests of this technology. However, the recovery ratio of Mn in manganese ore is low and fluctuates greatly due to various reasons such as inadequate hot-metal

201924 quantities of high-grade mineral ore deposits. 1.1.2 Development If the mineral ore exploration phase proves that there is a large enough mineral ore deposit, of sufficient grade, then the project proponent may begin to plan for the development of the mine. This phase of the mining project has several distinct components.

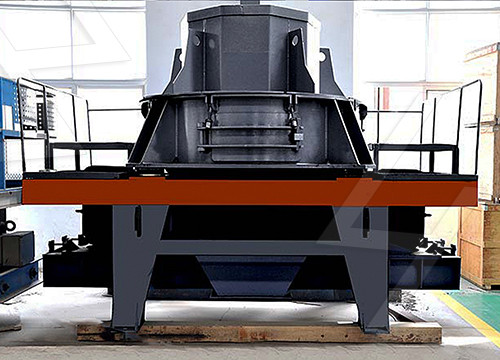

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين