China Vibrating Mill manufacturers Select 2023 high quality Vibrating Mill products in best price from certified Chinese Mill, Mill Machinery suppliers, wholesalers and factory on

2020331 In a nutshell, Metso Vertimills® ofer the most optimum equipment solution for the circuit. The Vertimill® is capable of handling feed sizes up to 6 mm and grinding to

HCH ultrafine grinding mill is a mineral ultrafine pulverizer machine that is mainly used to produce fine powder, this ultrafine mill is applied in grinding non-metallic mineral ores

The whirlwind mill an all-rounder. Wide range of bulk materials. The whirlwind mill can be used to grind soft to medium-hard bulk materials for a wide range of applications. It can grind a variety of rocks, minerals and

2019111 N E Bogdanov Abstract In many industries millions of tons of various materials are subjected to fine grinding. It is relevant to improve the quality of final

Features. 1.Grinding times are 10 to 20 times faster than conventional rotating ball mills. 2.Wide range grinding from crushing to fine grinding. 3.Simultaneous execution of grinding, mixing and dispersion. 4.Available

202363 Wfm Super-Fine Vibration Grinding Mill Vibrating Ball Mill Vibromill, Find Details and Price about Grinding Mill Vibration Mill from Wfm Super-Fine Vibration

20231013 The vibrating disc grinder is suitable for non-destructive crushing and fine grinding of larger particle size samples. It can quickly prepare samples with analytical grade fineness and purity. Grinding

China Fine Grinding Mill manufacturers Select 2023 high quality Fine Grinding Mill products in best price from certified Chinese Grinding Mill, Mining Mill suppliers, wholesalers and

2007720 Abstract. An effective fine grinding technology for y biomass using a new vibration mill is proposed and evaluated in this study. Grinding properties of y

The SAG mill was designed to treat 2,065 t h −1 of ore at a ball charge of 8% volume, total filling of 25% volume, and an operating mill speed of 74% of critical. The mill is fitted with 80 mm grates with total grate open area of 7.66 m 2 ( Hart et al., 2001 ). A 4.5 m diameter by 5.2 m long trommel screens the discharge product at a cut size

Contribute to changjiangsx/sbm development by creating an account on GitHub.

2021715 The process of particle size reduction has to be progressive and will generally entail several milling steps using different grinding principles: cutting mills for initial coarse size reduction (from cm to mm range), impact mills for intermediate grinding (from mm to 100 μm range), and ball or jet mills for fine and ultrafine milling (50–10

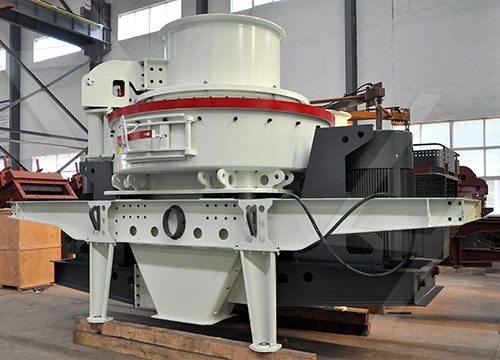

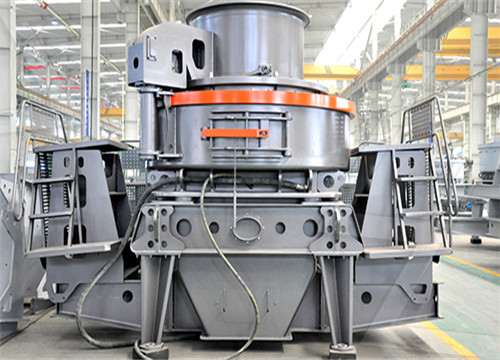

20221130 Advantages of Vibration Mill. 1. Suitable for hard abrasive grinding stocks. 2. Unlike tumbling mills, the porcelain in the vibrating mills move only a few millimeters through a complex path, shearing and impacting the materials between them. 3. Higher grinding rate in the range of fine particles.

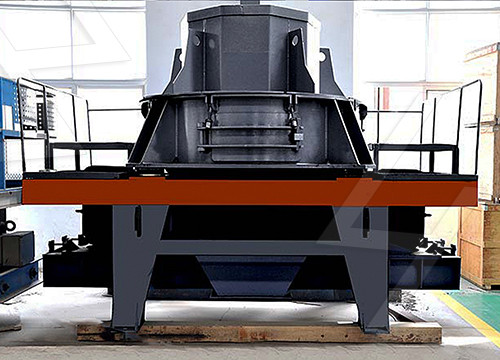

Vibrating Mill. The vibrating mill GSM is a vibrating mill with exchangeable grinding barrels used to crush brittle and fibrous material down to high degrees of fineness. The size reduction is achieved by impact and friction inside two vibrating grinding barrels which are filled with freely moving grinding balls.

Quantum Nanostructures (QDs): An Overview. D. Sumanth Kumar, H.M. Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3.6.1.1 Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball

1 Many grinding mills are still in service after more than 40 years of almost continuous operation. Ton for ton of material handled, the cylindrical type mill has proved to be the most economical investment for reducing moderate to extremely abrasive materials. Vibrating screens with screen cloth as fine as 28 mesh are used to produce a mesh

Contribute to crush2022/mill development by creating an account on GitHub.

Vibrating Mill Vibrating Mill. The vibrating mill GSM is a vibrating mill with exchangeable grinding barrels used to crush brittle and fibrous material down to high degrees of fineness. The size reduction is achieved by impact and friction inside two vibrating grinding barrels which are filled with freely moving grinding balls.

Vibrating Screens 2018 11 5 Vibrating Screens.Vibramech vibrating screens are custom designed for client needs and cover a vast range of sizes and unique process applications.Our screen design makes use of Finite Element Method and Strain Gauge Analysis to prove structural integrity. Stamler Coal Crusher Stone Crusher Machine

VIBRA-DRUM® Grinding Mills excel over conventional ball, stirred media, or vertical roller mills in both grinding and energy efficiency. The features listed below highlight why our mills are so effective and efficient. Proven

20201218 For a wide range of applications, from soft to extremely hard products, which require ultra fine grinding, surface activation or homogenization, the vibrating mill is well proven.

2020520 wear zone in the eccentric vibrating mill is distributed more uniformly on the bottom half of the plating. With the image "Absolute movement of the grinding bodies in the eccentric vibrating mill", the circulation movement of the grinding-media filling can be dis-cerned, which undertakes transport of the milled ma-terial and homogenisation of

Model F Pulva Sizer 125-300 HP. The Model F is a Pulva-Sizer™ designed for very high production of granular to medium-fine grinding and milling. It can produce 75% higher capacities than our Model D and can be driven by 125 to 300 HP. The unit is furnished with a multi v-belt or direct drive.

Model NO.: Grain grinding machine Type: Vibration Mill Condition: New ISO9001:2000: Stainless Steel Origin: Xinxiang City, Henan Province, China

201971 A ball mill, which is used to finely grind materials, causes high levels of vibration and sound during grinding operations. The vibration and sound of mills provide significant information about

Stirred Mills Ultrafine Grinding. In Mineral Processing Design and Operations (Second Edition), 2016. 10.2.4 Operation of Vertical Mills. Vertical stirred mills are usually charged with media occupying 80% of the mill volume which is in sharp contrast to tumbling mills that are seldom charged more than 40% of their volumes to allow space for the tumbling

2022417 Our small vibrating ball mill diameter is less than 900mm, volume is less than 1000L, power is less than 90kw. Our mills have successfully adopted for grinding silica, quartz, talc, zirconia and kaolin. 1. Iron free vibration mill for grinding ultrafine silica power. The finished produce size: d100=8-9um, d97<5um, d50=1.08-1.1um.

8.3.2.2 Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11 ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين