2019328 A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks. The equipment was first

The capacity is primarily a function of: 1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed side settings, 3. options on feeding

2023621 Jaw crusher is crushing equipment that works with two jaw plates, one fixed and the other movable. The movable jaw plate approaches the fixed jaw plate

20231022 A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dust. It does this by placing two jaw plates perpendicular to

202315 What Is A Jaw Crusher? A jaw crusher is a type of mechanical equipment that is used in the mining and construction industry to crush rocks and large materials

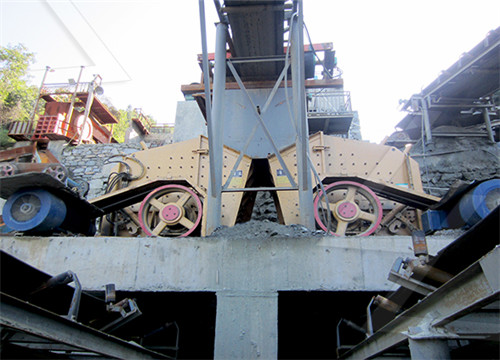

2021218 A jaw crusher essentially crushes large rocks to a more usable size. They’re typically the first-line machinery used in the material reduction for several applications. This includes rock quarries, sand and

2 All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts

All jaw crushers feature two jaws: one of which is fixed while the other moves. The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or

2019912 In general, the jaw crusher has a high production efficiency. This type of equipment is one of the more common crushing machines and has been widely used in

201611 The factors of importance in designing the size of primary crushers, such as a jaw crusher, are: (4.1) Vertical height of crusher ≈ 2 × Gape (4.2) Width of jaw > 1.3 ×

202327 jaw crusher A crusher is a machine designed to reduce large solid objects into smaller pieces by applying force, typically through compression or impact. The main functions of a crusher include: 1.

2021110 A jaw crusher is used in a wide variety of applications, including construction and recycling demolition, quarrying and mining, asphalt production, etc. It is designed to process large feed size and to

The jaw crusher reduces the size of large rocks by dropping them into a “V”-shaped mouth at the top of the crusher chamber. This is created between one fixed rigid jaw and a pivoting swing jaw set at acute angles to each other. Schematic diagram depicting the basic elements and function of a cone crusher. A working cone crusher (Fig. 13

2022222 A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism. The jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it

2022914 The jaw crusher toggle plate is a cast iron casting made of special alloy after accurate calculation. It is not only a force transmission component, but also an insurance part of the jaw crusher. When the unbreakable material falls into the crusher and the machine is overloaded, the jaw crusher toggle plate will be broken immediately, and

20231022 A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dust. It does this by placing two jaw plates perpendicular to each other and squeezing the rock between them until it is broken into small pieces. A stationary jaw plate and a movable jaw plate control the movement of these jaw plates.

201762 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl liner.Gyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface. As the gap

2019530 Double Toggle—Blake Type or Overhead Pivot Movement. Double toggle movement jaw crushers like the Blake style (named for the inventor of the first successful mechanical jaw crusher, Eli Whitney

. A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials. The RETSCH jaw crusher range is primarily used in laboratories and pilot plants under rough conditions but are also suitable for on-line quality control of raw materials. The main fields of

2022627 A fixed jaw plate mounted within the crusher main frame, and a movable jaw plate mounted to a jaw stock comprise the jaw crusher.On the insides of the jaw crusher, cheek plates serve as additional wear parts to protect the crusher mainframe.The two jaw plates are arranged in a V-shape, narrowing the space from top to bottom.

20221214 Pi tman is the main component of a jaw crusher that forms the moving part of the crusher. It functions as the link between the stationary and the moving jaw. The pitman is responsible for transferring

201611 Currently, the dimensions of the largest Blake-type jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW. Crushers of this size are manufactured by Locomo, (Metso) and others. The Metso crusher is the C 200 series having dimensions 1600 mm × 2000 mm driven by 400 kW motors. Table 4.1.

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits.

A jaw crusher mainly works on the principle of reciprocating motion exhibited by the moveable jaw of the jaw crusher. The repeated movement of the jaws results in the development of compression force that further causes the breakdown of the rock or the ore placed between the two jaws into smaller pieces. The movement of the jaw crusher is

4.4 Jaw Crusher Capacity Estimation. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed side settings, 3.

2023215 Columbia Steel: Columbia Steel is a leading manufacturer of crusher wear parts and offers a wide range of products, including jaw plates, mantle and concave, blow bars, and impact plates. Their wear parts are known for their superior quality and durability. AGICO Cement: AGICO Cement is a professional supplier in China that offers a

20181226 3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary Breakers 48 The goal of a crusher is to crush the given material in to the material with certain size and shape. Information about crushing technology, construction, working and maintenance of

2017630 Moreover, the wear of the jaw liner profile lowers the crusher performance by affecting the shape and the overall size of the crushed particles [12, 13]. Warping and wear of the jaw plate cause a

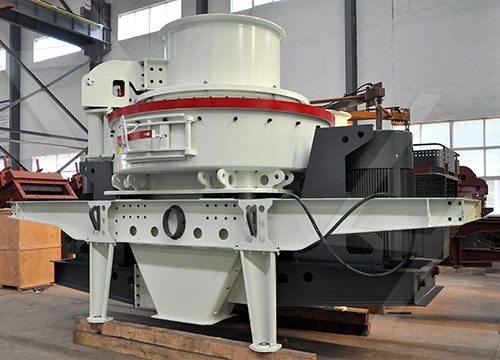

Capacity. 1-1120t/h. Output Size. 10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications. mining, quarry, construction waste recycling, aggregate making, etc. Materials.

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين