20041210 The impact of material properties in grinding processes is twofold: • the objective of the comminution process is the production of well-defined product properties, • particles' transport to the stressing zone and particles' reaction to applied stresses

202111 The main objective of this work is to evaluate the influence of grinding media on the physical and chemical properties of carbon materials mixed with PC and biomass.

202153 Besides, the formation of grinding marks is affected by a variety of factors, including the type of processed material, wheel vibration, grinding wheel run out error,

202371 Grinding force strongly affects material removal rate, dimensional and shape accuracy, surface and subsurface integrity, grinding thermodynamics, dynamics, wheel

2021225 According to the study on effect of grinding treatment on surface properties and deformation microstructure in 304L alloys, the following conclusions could be drawn:

20211211 Abstract. The breakage and liberation of minerals are the key to fluidized mining for minerals. In the ball milling process, steel balls function as not only a grinding action implementer but also energy carrier

2004121 The impact of material properties in grinding processes is twofold:•the objective of the comminution process is the production of well-defined product

2021617 Metrics Abstract Engineering ceramic has been widely used in various fields, especially in bearings, for its excellent characteristics, such as the outstanding

202132 Grinding process is an important method to machine these difficult-to-cut metal materials. However, the thermomechanical coupling effect in grinding process has

2021518 The grinding residual stress is always composed of three major factors, which are the material’s plastic deformation from the mechanical factor, the thermal

20181126 Material Head Dry (R 45%) Wet (R45%) Coal 20.51 30.58 33.25. Dolomite 57.22 65.76 70.27. Manganese 38.47 40.66 52.19. Iron Ore 24.11 25.42 38.53. Effect of materials morphology on wet grinding

2016101 The cryogenic and ambient grinding of fenugreek seeds was reported to influence the specific energy requirement for grinding and flowability of the powders [17], [18] significantly. Further, the particle size of the superfine ginger powder was reported to have a significant effect on the physical-chemical properties of the powder [19].

202081 Single-grain grinding tests are performed to reveal the wear properties and material removal mechanism of AcBN grains. Section 2 shows the starting materials to fabricate AcBN grains, single-grain grinding setup, and 3D quantitative characterization technique. which have a strong effect on the grinding force, shape accuracy and

202121 In general, grit wear associated with grinding is a complex dynamic process, and its effect on the grinding performance is difficult to control. It is thus important to maintain constant wheel sharpness during the course of ductile grinding. The widely adopted BDS model usefully imports material properties into a relation for critical depth

2023316 The surface/subsurface damage of engineering ceramics after machining has a great influence on the service performance of parts. In order to obtain a high grinding surface quality of engineering ceramics, and take silicon nitride ceramic as a research object, a series of grinding experiments were carried out. The effects of grinding

2021225 Different types of sandlimestonewere used to grind surface of 304L alloy, and the effects of grinding treatment on surface properties and deformation microstructure were studied. Three dimensional profilometer, Vickers hardness tester, X-ray diffraction (XRD), scanning electron microscopy (SEM), focused ion beam (FIB), and transmission

2022527 The main chemical component of high-silicon iron tailings (HSITs) is SiO2; HSITs also include some oxides such as Al2O3 and CaO. Mechanical activation can reduce the particle size of HSITs and enhance their pozzolanic activity such that they can be used as a type of mineral admixture for cement-based materials (CBMs). This study aims to

202295 The current state-of-the-art applications of GF as sand replacement in sustainable concrete have been systematically reviewed in this stone based on recently published works. Feasibility of using GF as sand substitution was verified in several reports. In addition, the effects of GF with different physical properties on fresh and hardened

2022815 1. Introduction. Monocrystalline silicon is widely used as the raw material for the preparation of integrated circuit (IC) chip wafers, and its processing involves a large number of complex ultra-precision processing techniques [1], such as grinding [2], etching [3], polishing [4], etc.According to Moore’s Law, the current etching size of IC chips has

202111 In this study, we evaluated the characteristics and applications of carbonaceous materials, which play a vital role in silicon production. Specifically, we conducted an exploratory study on biomass and petroleum coke (PC) performance improvement in response to different grinding media, and discussed the outcomes of our

2018428 Grinding is a staple size-reduction process to produce powders in which the powdered form is chemically and microbiologically stable and convenient to use as end products or intermediate products.

2018929 The efficiency of the mechanochemical activation (MCA) is influenced by various process parameters as well as by the properties of the treated material. The main objective of this research was to optimize the

2019420 In this study, ground coal bottom ash (CBA) and titanium-extraction tailing slag (TS) were used as source materials to prepare alkali- activated materials (AAMs). The effects of grinding time on the properties of CBA and TS were investigated, and it was found that the optimum reactivity of CBA and TS appeared at specific surface areas of 700

2020130 Freeze-drying is an important processing unit operation in powder production. It offers dehydrated products with extended shelf life and high quality. Unfortunately, quality attributes and grinding characteristics are affected significantly during the drying process due to the glass transition temperature (during drying

2022120 A molecular modified PCE-type GA was self-synthesized, and the grindability concerning grinding duration and particle size distribution of ground cement was evaluated. Setting time, flowability, hydration heat, mechanical properties and microstructure of the ground cement were also investigated. The results show that: PCE-type GA is

201011 The effects of grinding aids, i.e. dispersants or additives, on grinding have been mainly explained by two mechanisms. One is the alteration of the surface and mechanical properties of individual particles, such as a reduction of surface energy, and the other is the change in arrangement of particles and their flow in suspensions (Bernhart et

202071 The theories based on surface and mechanical properties have failed to explain the effect of GAs in grinding. Therefore, it is the prevailing mechanism of effect is one based on the particle arrangement and material flow properties. The mechanism based on the material flow properties can be illustrated using Fig. 1. At low flowability (adding a

202051 Based on the review of above associated literatures, the wear mechanisms of alumina abrasive wheels are affected by many factors, such as the grinding modes [11], material properties of workpieces

202371 The material properties of the workpiece affect the material removal mechanism, thus affecting the generation process of grinding force. Effect of grinding wheel ultrasonic vibration on chip formation in surface grinding of Inconel 718. Int J Adv Manuf Technol, 86 (2016), pp. 1113-1125. CrossRef View in Scopus Google Scholar. 97.

202371 Using the cutting fluids plays a decisive role in prolonging the tool life, enhancing the machinability, and improving the machining sustainability during the grinding operations. 16, 17 The metalworking fluids could be delivered to the grinding zone in different ways, and the cooling/lubrication function was done by various techniques such

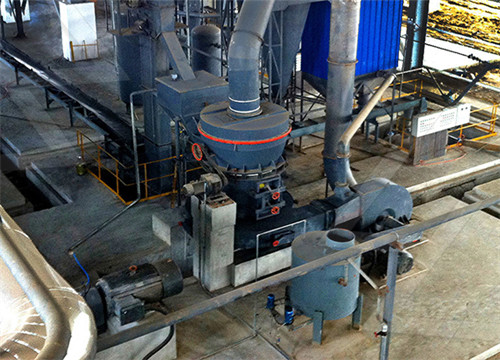

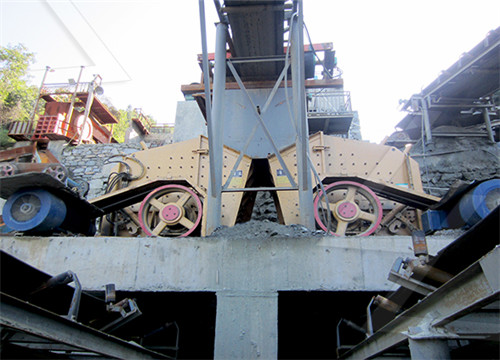

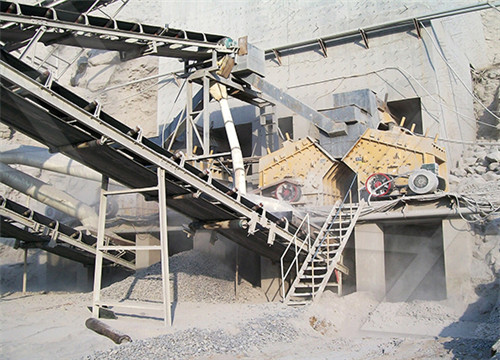

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين