20231026 Types of Concrete Crushers A) Concrete Crusher of Jaw. The most uses of primary jaw crushers using the same technology for a

There are many different variations of concrete crushers, but we’ll talk about the three main types; jaw crushers, impact crushers and cone crushers. Jaw Concrete Crusher Jaw

2022-12-19. Summary: One of the most popular types of crusher for concrete is the jaw crusher. This type of crusher uses a powerful engine to compress the concrete, breaking

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on

2023819 There are many types of concrete crushers available on the market. Here are the 3 major ones; Jaw Crushers Jaw crushers use two elongated jaws that rotate back and forth to crush heavy-duty

2023105 The two most common types of concrete crushers are double toggle (blake type or overhead pivot movement) and single toggle (overhead eccentric movement).

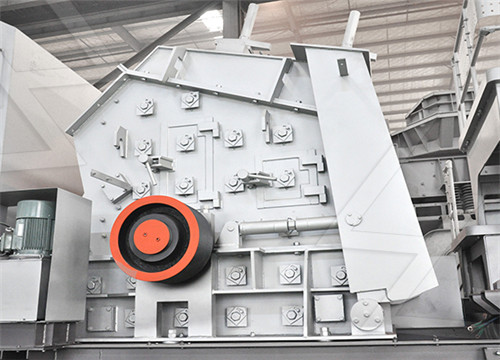

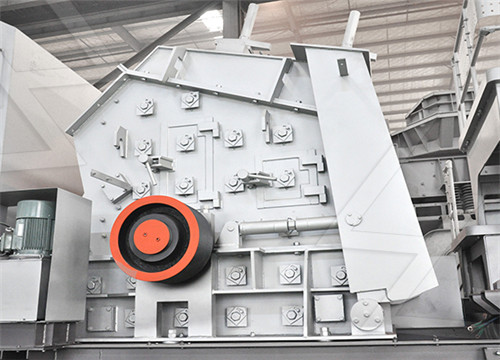

2020319 Designed to fill the gap left in the market by cone and jaw crushers, horizontal impact crushers are ideally suited to contaminated materials and can easily handle any clay, dirt or metal mixed in with the

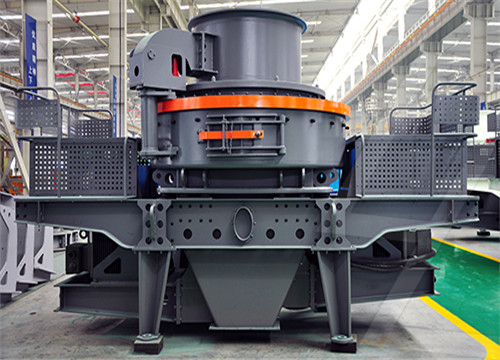

20201217 Impact crushers are traditionally classified into two main types, horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers. These different types of impact crushers share the crushing

2018910 Cone and gyratory crushers Cone crushers and gyratory crushers are also compression-type machines that crush material between a moving piece of steel and a

These are split into two main types: horizontal shaft impactors (HSI) and vertical shaft impactors (VSI). HSI crushers are limited to soft materials only, so aren’t well suited to concrete and are better for soft sedimentary rocks. VSI crushers work differently. A high speed rotor “throws” the input material against an inner crushing

2023527 Cone crushers and jaw crushers both perform well in quarries, aggregates plants, sand making plants, cement plants, etc. However, many still do not know which one to choose. To help you decide, now let's dive into the differences between cone crushers and jaw crushers. 1. Different production characteristics

March 14, 2023. 1. 8768. Crushing and Screening Equipment for Concrete Recycling. There are two approaches to recycling concrete. One approach is to haul the concrete debris to a permanent recycling facility or quarry for

20231025 Crushers are used to reduce the large rock or boulder sizes to smaller and uniform sizes acceptable for concrete mix. Common types of crushers are jaw crushers and hammer mill crushers. Also Read Tools Used In Plastering 40+ Tools Used In Construction. Follow our Facebook Page, Linkedin PageTelegram Channel. Share

2022322 1. According to the driving way, it is divided into tire type and crawler type: the tire type concrete crushing and sorting machine needs semi-trailer traction to run, while the crawler type can be remotely operated with buttons. Relatively speaking, the latter is more intelligent and the price is more expensive. 2.

20191111 There are many types of crushers, but their main job is the same: Crush larger rocks into smaller pieces to be used for construction material. Sandstone: A sedimentary rock used primarily for concrete and masonry work. It is unsuitable for use as a building stone because of its sediment composition. Slate: A metamorphic rock typically

2022103 The jaw crusher is one of the most common types of concrete crushers. It is a simple machine that uses two metal plates to crush concrete. Jaw crushers offer unique benefits over other types of crushers. For example, jaw crushers can handle larger chunks of material than other types of crushers. This makes them ideal for breaking down large

2018910 Cone crushers and gyratory crushers are also compression-type machines that crush material between a moving piece of steel and a stationary piece. The output is controlled by the setting between the two pieces of steel. 31/10/2023 11:53 Concrete. Most Popular. HS2 decision ‘worst of both worlds’, says MPA 04/10/2023 14:43 Mineral

2023414 Concrete crushers come in various sizes and types, from small handheld devices that can be operated by a single person to large industrial machines that require specialized training and expertise

2019928 All types of these concrete crushers adopt laminating crushing principle, whose finished products have uniform grain size, less stone powder. However, when the fixed jaw crusher is used as a concrete pulverizer, it is more suitable for customers who do not require a large amount of processing. Different types of concrete crusher will lead to

2021325 Like the other Roll Crushers listed, Triple and Quad Roll Crushers produce a cubical product with minimal fines generation. Cone Crushers. Cone Crushers are compression-type crushers that are

1 Choosing the right crusher. A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks

20221017 5 Main Types of Concrete Crushers Jaw Crusher. A jaw crusher is a type of crusher that uses two metal plates to crush rock. It is one of the most common types of crushers and is often used in

2020916 Impact crushers can be applied to processing those schistose ores with mid-hardness. The above are the five types of crushers in the mineral processing, including jaw crusher, cone crusher, impact

To smooth and level roads under the pavement. Enhance soil to improve crop growing conditions. Stone fill to support pipes and drainage beds. Protect roofing and reduce the heat from the sun. Prevent ice and water erosion when building bridges. As a buffer layer between concrete and soil.

201734 5.0 Types of Crushers: A crusher is a machine designed to reduce larg e rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form, of waste

20231026 So if you want to buy Concrete crushers to start the concrete crushed stone business, please go ahead. Request A Free Quote. 3 Types of Concrete Crushed Stone. The particle size of concrete crushed stone is usually between 5mm-31.5mm. Because the size of crushed stone is inconsistent, when using the vibrating screen for

2023215 At present, there are two kinds of crushing production lines for processing concrete waste, one is fixed concrete crushing production line, and the other is mobile crushing production line. 1. Fixed crushing production line for concrete waste. The fixed type is suitable for some stone factories and concrete wastes need to be equipped with

2023822 Komplet North America is your source for high-performance mobile crushing solutions including compact crushers for constructiondemolition waste materials (908) 369-3340 info@kompletamerica Request Quote. Home; Equipment. CRUSHER. K-JC 503; K-JC 604; K-JC 704 Types of Cement Crusher Machines. April 27, 2023

201911 The coarse aggregates obtained by different crushing mechanisms (jaw and impact crushers) show very similar characteristics in terms of binder content assessed by acid leaching (27.5 and 26.6 wt.%), water absorption (8.76 and 9.75 wt.%) and porosity (18.6 and 20.2 vol.%).Thus, it is not possible to conclude that any of these mechanisms

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين