Unrivaled leadership, performance, and versatility. Features. Metso continues to pioneer innovations in horizontal grinding mills technology with over a century of leadership,

Every mining operation has a unique grinding process. Metso has experience of over 8,000 grinding mills globally. Reliable, energy-efficient technology and solutions across wet,

Services Home Mining Grinding and Processing Grinding and processing WEG offers the most reliable and efficient solutions for milling plants for ferrous and non-ferrous products

China Grinding Mills manufacturers Select 2023 high quality Grinding Mills products in best price from certified Chinese Grinding Machine, Grinding Equipment suppliers,

China Mining Mill catalog of Gold Mining Machine Ball Mill Grinding, Wet Ball Mill Machine, Wet Grindng Ball Mill, Grinding Mine Mill for Sale, Iron Ore, Copper Ore, Limestone,

1 Introduction: The ball mill is a tumbling mill that uses steel balls as grinding media. Ball mills can be used in wet or dry systems for bulk and continuous milling, and are most widely used in small or large-scale ore

20131218 Grinding activities in general (including coarse, intermediate, and fine grinding) account for 0.5 pct of U.S. primary energy use, 3.8 pct of total U.S. electricity

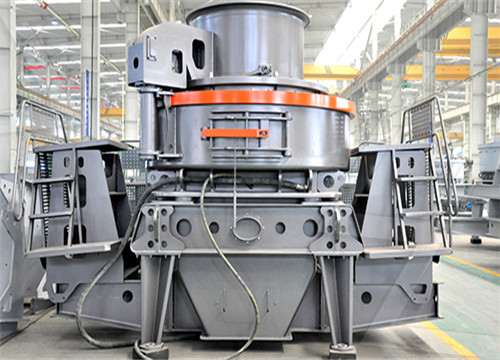

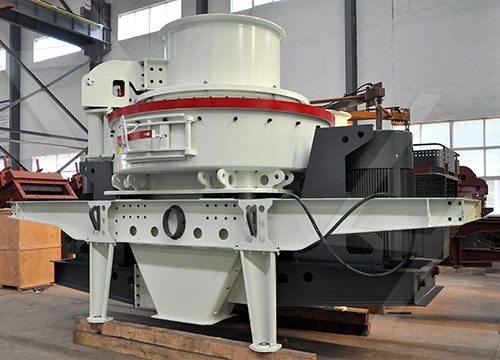

2021726 Mining grinding mill are used to reduce the size of materials through grinding and crushing. Size reduction is an important part of a wide variety of industrial processes. Grinding mill suppliers provide

Future circuits may see increasing use of high pressure grinding rolls ( Rosas et al., 2012 ). Autogenous grinding or semi-autogenous grinding mills can be operated in open or

200921 Abstract. A worldwide survey on grinding mill circuits in the mineral processing industry was conducted. The aims of this survey are to determine how milling circuits are currently controlled, and

2016117 The types of mill normally encountered can further be classified according to the method of feeding the raw material to, and the removal of the final product from the mill. These classes are: Batch mills.

201588 The mill can be fed from one end with the product removed from the other end or, alternatively, the mill can be fed from both ends with the discharge at the centre. The process can be wet or dry but is more commonly carried out wet. Maximum rod length is about 6 to 7 metres, otherwise there is a risk of the rods bowing. The

Stirred Media Detritor (SMD) is a fluidized, vertical stirred mill designed for optimum grinding efficiency for fine and ultrafine grinding products. SMDs have the capacity to operate continuously at full load power draw with no steel contamination of the product. They are suitable for both open- and closed-circuit operation.

Metso HIGmill™ advanced and energy-efficient fine and ultra-fine grinding solution. The HIGmill™ comprises a mill body, shaft with grinding rotors, shell mounted stator rings, gearbox, and drive. The grinding chamber is filled up to 70% with inert ceramic grinding media beads. Rotors stir the charge and grinding takes place between beads

202211 Abstract. The maintenance of industrial mining machines is a challenging process, especially in the case of critical assets, as it impact the hole process: for instance the grinding mills. However, many approaches have been developed by the growth of the mining industry in order to reduce the cost and optimize the time.

202063 The design process has changed dramatically with computers though. A typical FEA of a grinding mill that would take about 3 hours on a minicomputer in the late 80’s takes about 3 minutes on a laptop computer today. This allows the analyst to add more detail to the models (increased accuracy) and check multiple options to optimize design

202291 This work considers a chain from mine to non-aqueous mineral processing operations, with a special focus on management of fine-grained (<50 µm) material (Fig. 1).The objective is to provide an overview and some selected examples of potential methods for energy-efficient production of valuable materials from complex ores, consider ways of

Unlike more traditional ring-geared mill drives where a ring-shaped gear encircles the mill and drives it through one or two pinions followed by conventional motors GMDs work by mounting rotor poles directly to the mill body and surrounding it with the stator ring, meaning the mill itself is incorporated into the motor.

2022330 HPGR-Ball mill circuits have the potential to reduce the Mining Industry’s CO 2 emissions by 16.3 megatonnes/year when compared to AG/SAG/Ball mill circuits. This saving climbs to 34.5 megatonnes/year if HPGRs are also used instead of ball mills. Despite this huge potential saving, uptake of HPGR technology has been relatively slow.

20231030 O. Mejia and B. Klein Maintaining grinding efficiency and mill throughput when liners wear, 51st Canadian Mineral Processors conference, 22-24 January 2019, Ottawa, Canada ABSTRACT A study was undertaken to investigate the relationship between mill liner wear and grinding energy efficiency and to...

202061 The first gravity-induced stirred mill was the Tower Mill, invented in the 1950s by the Japan Tower Mill Company, and in the 1980s Metso developed the Vertimill, which is an adaptation of this technology [22]. Early uses included wet grinding of limestone used for neutralisation purposes [23], and by the 1980s and 1990s, gravity-induced

Here, all the objective functions and constraints are not only function of decision variable set X, but also two sets of parameters, denoted by τ, ω.The parameters indicate the following: ball mill and rod mill grindability indices— τ 1 τ 2, primary and secondary cyclone sharpness indices— τ 3, τ 4, ball mill and rod mill grindability exponents— τ 5, τ 6, and finally four

2020616 In SAG mill 1, the rRMSE curves have convex behaviors, responding to the known principle of underfitting and overfitting the training dataset when models have low and high complexities, respectively. The optimum numbers of hidden units that deliver the minimum rRMSE are different from time supports, on both methods. In SAG mill 2, the

201611 The designs of autogenous and semi-autogenous (SAG) grindings mills are described followed by the description of their methods of operation in grinding circuits involving crushers and ball mills. Methods of estimating SAG mill volumes, mill charges, feed size and power consumptions and optimum speeds of rotation during operation are

A holistic approach to help with your mining challenges. Maximizing the recovery of valuable minerals at a saleable concentrate grade, at the lowest cost and with the lowest environmental impact requires optimizing all processes and sub-processes linked to the flow sheet. Our concept of optimization considers the entire value chain: Process

An autogenous mill of ID 6.7 m and an effective grinding length of 2.1 m was fed with ore of SG 3.8 to 20% of its volume. The mill was operated continuously 24 hours per day at 1200 t per day and 75% of the critical speed. The solids

200811 Abstract: A worldwide survey on grinding mill circuits in the mineral processing industry was conducted. The aims of this survey are to determine how milling circuits are currently controlled, and to find out how key process variables are linked to economic benefits. The survey involves background information on the circuits, the

20231030 The IsaMill™ has real-world success in 143 metalliferous installations across 23 countries. It’s the world’s only horizontal fine-grinding mill, so it avoids short-circuits, is highly efficient and gives the highest availability. IsaMill™ has 100% accurate scale-up and is proven consistently. It’s easier to maintain, has no height

20211211 The breakage and liberation of minerals are the key to fluidized mining for minerals. In the ball milling process, steel balls function as not only a grinding action implementer but also energy carrier to determine the breakage behavior of ores and the production capacity of the mill. When ground products present a much coarse or much

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين