20181129 Cone crusher is a primary crusher, used in mining or Ore processing. It reduces large aggregates to smaller aggregate. VSI means, 'Vertical Shaft Impactor'. In which shaft and crushing chamber are in a vertical position which is a latest crushing

20221212 The vertical shaft impactor can crush both hard or soft rocks effectively which makes it more versatile while the cone crushers is more suited for crushing

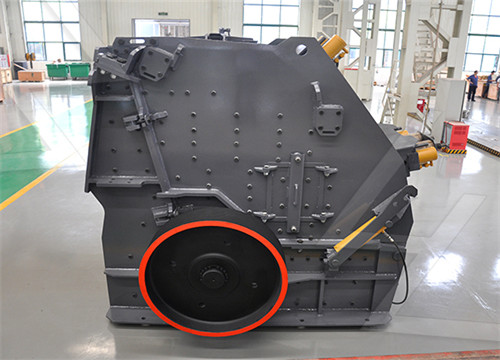

2023914 What is the difference between Impact Crusher and Cone Crusher? In general, impact crushers both vertical shaft (VSI) and horizontal shaft (HSI), the main

2013221 Vertical shaft impactor crusher (VSI) and cone crushers are types of crushing machines which reduce the size of rocks. Large rocks can be turned into

2020818 Compared with impact crusher, cone crusher has the characteristics of low energy consumption, large output and stable production, so cone crusher is often used in

Watch on Impact vs Compression Rock crushers are first categorized by the general crushing mechanism. Compression crushers include jaw crushers, cone crushers, gyratory crushers and roll crushers. Impact crushers

20201217 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes

20231027 Although Impact Crushers generally have a higher operating cost than other crushers, they tend to produce a more uniform particle shape (cubical) which is

201791 Vertical Shaft Impact (VSI) crushers have been used as interesting alternatives to cone crushers, particularly in the production of aggregates for the

200881 The vertical shaft impact (VSI) crusher is a commonly-used machine in aggregate production. A comprehensive understanding of the physical phenomena that

20231027 Impact Crushers produce the most uniform cubical shape for finished products, due to its consistent ability to uniformly break apart aggregates through striking. Striking can be done with rapid moving hammers as seen on the Horizontal Shaft Impactor or being thrown against an anvil or rock wall as seen on the Vertical Shaft Impactor.

20181129 VSI (Vertical Shaft Impactor) Cone crusher is a primary crusher, used in mining or Ore processing. It reduces large aggregates to smaller aggregate. VSI means, 'Vertical Shaft Impactor'. In which shaft and crushing chamber are in a vertical position which is a latest crushing technology. The crushing action is caused by the closing of the gap

2021123 Concerning cone and vertical shaft impact crushers, rock aggregate quality was investigated for products with a particle size range of 33-63 mm. Cone crusher c) Vertical shaft impact crusher d

20201217 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

201762 The impact, using the principal of surface force, breaks the material, reducing it. to a size 1/10 to 1/25 of the original. VSI crusher. Vertical shaft impactors (VSI) have a vertical shaft and enclosed rotor that turn at high speeds. There are two main types of VSI crushers, rock-on-rock (autogenous) and shoe and anvil.

2022214 Vertical shaft impact crusher is also called sand making machine.With its unique rotor structure design, wear-resistant material process, crushing speed optimization and hydraulic design, it can provide high quality sand and gravel aggregate for highway, high-speed railroad, municipal construction, hydropower dam construction and concrete

2020414 f) Select the relevant crusher from the capacity tables =CV228. TONNAGE THROUGHPUTS It is vitally important that the correct size of crusher is selected for the required application. Be aware that when operating the crusher in closed circuit, the total crusher load needs to be used in calculations (raw feed plus return feed).

20211112 The Discrete element method (DEM) is an invaluable tool for studying comminution as it provides detailed information that can help with process analysis as well as trying out new equipment designs before the equipment is physically built. The DEM was used to analyse previous experimental work to gain some insight into the comminution

Cone Crusher Applications. Cone crushers, a type of compression crusher, have less versatility than a horizontal impact crusher, but a great capability to guarantee a finished product size. If set at 2”, typically 80% of the final product will meet the 2” target which is not something that can be replicated by jaw crushers or impact crushers.

202344 The material is crushed and falls out through the bottom of the machine. Cone crushers are known to produce good quality GSB and Railway Ballast material. Impact crushers, on the other hand, are used for tertiary crushing applications. Impact crushers consist of a high-speed rotating rotor, which accelerates the incoming new feed to high

difference between hammer mill and impact crusher 8211; Grinding mill material through crusher the economical cage paktor features an impactor Hammer Mills,Horizontal Shaft Impactors,Vertical Impactors

The cone crusher is a modified gyratory crusher. The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 8.2). Power is transmitted from the source to the countershaft to a V-belt or direct drive.

20151028 Crushing takes place between a fixed outer crusher member (the concave ring) and a moving inner crushing member (the mantle) mounted on the gyrating shaft assembly. A roller-bearing type

2006121 Particle shape characteristics were assessed from flow measurements in a standard cone. The vertical shaft impact crusher (VSI) produces gravel that is a good alternative to natural gravel. The

2023118 Difference between cone crusher and impact crusher Scope of application. The vertical shaft impact crusher is equipped with a thin oil lubrication station, which automatically stops when there is no oil flow and oil pressure, ensuring that the bearing lubrication is always in the best state and prolonging the service life of the equipment.

2021325 Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, clinkers, quicklime, petroleum coke, coal and more. Using a combination of impact, shear and attrition reduction methods,

Impact crushers are versatile crushing machines that can be used in any stage of the crushing process. However, the features and capabilities of different impact crusher types vary considerably. Impact crushers are traditionally classified to two main types: horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers.

200881 The vertical shaft impact (VSI) crusher is a commonly-used machine in aggregate production. One common application of the crusher is for the production of cubical particles in all fraction sizes. VSIs produce a larger amount of fine aggregate in comparison to a cone crusher; desirable products of the aggregate producer often include those with

2023228 Vertical shaft impact crushers (VSI) are commonly used in the production of high-quality manufactured sand and are ideal for producing a cubical-shaped product. Cone crushers are well-suited for producing a fine product size, while roll crushers are used for producing a finer product size and are often used in the mining industry.

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين