2015910 Water is sprayed onto the material throughout the screening process. After screening, the sized gravel is transported to stockpiles, storage bins, or, in some cases, to crushers by belt conveyors, bucket elevators, or screw conveyors. The sand is freed from

The Derrick ® Repulp Wet Sizing Screen is the solution for difficult to screen materials that require the Oversize product fraction to meet tight quality

202298 Classification / safety screening / de-dusting of bulk materials of all industry branches. Especially suitable for fine screening and precise classifications up to 6

20231025 These dewatering screens remove the remaining water within the sand so that only 10-15% of water is left. The sand that is now up to spec is then transferred onto

Dewatering Screens can be used to dewater -4 mesh (5 mm) particles of sand, coal, iron ore, salt, etc., as well as for limited efficiency fine sizing, washing and rinsing, desliming

In this case, focus the water and water pressure on the top deck and add more spray bars and/or nozzles, to that deck. Spray bar nozzles should be oriented at 45 degrees back toward the feed end of the screen. This

20231026 The ® Fines Materials Washers are specifically engineered to provide the highest quality sand production through efficient washing, classification and dewatering. The range consists of 3 models,

wash water spray also scrapes any sticky or fine solids off the filter elements. With more than 6,000 references delivered over more than 40 years, and recognized as the most

Spray Technology for wet Screening on mine sites from the experts at Spraying Systems Co.

2020319 Widespread wet options in mobile washing plants. Pecisionscreen, which has numerous national outlets, has outlined the benefits of its wash plant inventory, which includes the SRD240x mobile

20211116 Material: Quartz Silica Sand Ore. Raw Condition: Raw ore is 4-200 mesh. The iron content of the ore is 200ppm, SiO2:99.58%. Capacity: 100TPH. Requirements for Finished Sand Products: particle

Precisionscreen have designed a water filter system to help condition the feed water to various types of sand washing plants. Water is sourced from a dam/pond through the suction hose. Unfortunately this allows fine particles of organics to pass through the foot valve and sent to the wash plant (anywhere up to 10mm particle sizes).

2. By connecting the two sand washers in series and the spray water pipes arranged around them, the material can be cleaner fully. 3. The fines recovery device can recover more than 90% of fines in the overflowing

2015726 Wash water or spray will increase the effectiveness of the screens with openings of less than 1 in. in size. In fact, a deck with water spray on 3/16 in. openings will be more than three times as effective as the same size without the water spray. SCREENING. For efficient wet or dry screening—Hi-capacity, 2-bearing design.

Using a dilute feed and additional spray water, these screens can effect some limited sizing. Dewatering Screens can be used for limited efficiency fine sizing at or above 10 mesh (2 mm) to create differential products, for stone washing and rinsing <2” (-50 mm) aggregates prior to loadout, desliming, and for trash/organics dewatering/screening.

Description Polydeck’s polyurethane spray nozzles are designed for one purpose: to deliver water to the screen deck to wash material. Unfortunately, components of spray systems — such as spray bar nozzles — are too often taken for granted and forgotten until they don't work. That’s why we’ve designed ours to be practically maintenance

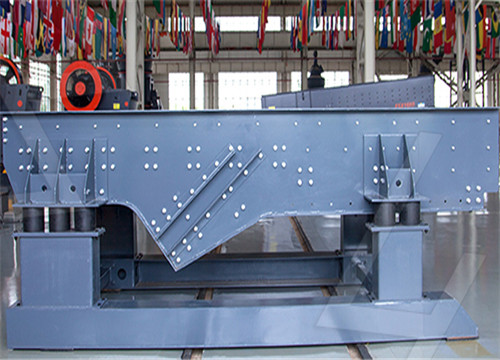

High-capacity wet and dry screening using panels that are constructed from a special high temperature polyurethane material. Vibratory screening equipment is used to screen or classify wet or dry materials, like wet ash or dry frac sand, into multiple grades by particle size. They are also used to dewater or dry waste material before disposal.

2022625 4) Less loss of cleaning materials and high cleaning efficiency, which can fully meet the requirements of high-end materials. 5) The service life is relatively long, and there are almost no vulnerable parts. 6) Maintenance is rarely needed, so the cost can be greatly reduced. 2. Drum sand washing machine. The drum sand washer is to make the

202114 2. Noise Control In The Silica Sand Washing Process. In the silica sand washing process, the noise source in the plant area is mainly the crushing and screening workshop of machine-made sand and gravel aggregates and the dust collecting fan. The control of noise pollution should mainly be controlled from the sound source and the

20231026 Propel Sand Washer ConstructionProcess. Propel Sand washers are the classic machines for recovery of sand from the discharge water with the assistance of dewatering screens. Propel Sand Washer produces high sand recovery (from 100 to 120) to increase production with a low running cost. Sand Washers require only low drive power

2022211 The M1700X is a redesign of the M1700 and improves the M Range of mobile washing screens manufactured by TWS that can produce up to five products (three aggregates and two sands) in applications including aggregates, recycling, industrial sands, and mining. The M1700X was featured alongside the FM120 C-2G, which allows sand to

2013416 screen, resulting in improved screening efficiency. Custom design Our entire screen range can be tailored to suit the unique needs of your specific application. Our expertise is spread across a wide variety of industries ranging from sand washing and classification plants and minerals and coal processing plants, to tailings dewatering

20231027 Alliance® Low Water Washer; Screening. Washing. Conveying. We wash sand and gravel for better roads and bridges, lasting foundations and — best of all — to command higher prices for our

This sand washing machine is designed based on sand washer and sand recycling system and adopted foreign advanced technology. lake sand or sea sand washing, screening, recycling and dewatering. Chat Line. Or Call Us Now +86-379-. FeaturesBenefits; Working principle; then fed to the polyurethane screen for dewatering from

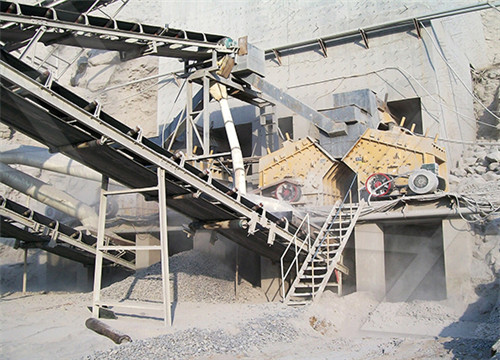

CrushingScreening Plants. Wet Processing. To produce standardised, clean and washed aggregates MEKA offers an extensive product portfolio to work in many applications supporting customers in the washing minerals industry. MEKA products have excellent reliability, are easy to transport, operate and provide fast onsite installation.

Sand Washing Method. 1. Wheel sand washing machine. The raw material goes into a wheel sand washing machine through the hopper for pre-screening. During the sand screening process, the sand from the vibrating screen feeds into the sand washer equipment through the bottom feed intake of the machine. The sieved big particles discharge pass

20231025 The water that, up until this point, has been used to initially rinse the feed material, wash the sand within the FM 200C and has been recovered from the dewatering screen is pumped into the 17-metre rake thickener tank. The rake thickener allows the silt and clay particles within the sludge to settle at the bottom of the tank, while the clean

20231030 cleaning these screens. Brush cleaning can have a lower capture performance compared to water cleaning because over time the bristles may bend or may become wrapped in screenings. Hot water provides better cleaning results than cold water because it helps to remove grease that has adhered to the surface. The common types

The level of demand for the recycled sand and aggregate products from this plant suggests that C&D recycling plants offer a real solution to a diminishing supply of virgin material in the UK. VIEW CASE STUDY. Repurpose It. Australia. Tonnage 150tph. Material C&D Waste, Excavation Waste, Non Hazardous Soils.

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين