2021212 Abstract. In-pit crushing and conveying (IPCC) systems are currently receiving more attention as a result of the existing characteristics of open-pit mining

20231026 The product types of XC INTELLIGENT are mobile Jaw Crusher, Cone Crusher, Impact Crusher, Shock Crusher, and Screener. Product Delivered To Customer

202091 Comparison of fixed and mobile in-pit crushing and conveying and truck-shovel systems used in mineral industries through discrete-event simulation. In-pit

202091 In-pit crushing and conveying (IPCC) systems (whether fixed, mobile, or semi-mobile) are an alternative to the traditional truck/shovel approach to materials

2019227 SlewiingLuffing Discharge Conveyor Length up to 39 m up to 128 ft Belt speed up to 2.4 m/s up to 467 ft/min Belt width 2400 mm 94.5 in Inclination Up to 14

Crushing and conveying. ABB has decades of experience with electrical equipment and automating systems in open-pit mining and material handling, with more than 700

2021922 Integrated continuous mining techniques such as fully mobile in-pit crusher and conveyor (FMIPCC) systems offer inherent labour, energy and environmental benefits to deep pit metalliferous...

2023109 SKE is a global manufacturer of crushers, mobile crushers, portable crushers, vibrating screen, belt conveyor, grinding mill, and mineral processing equipment in China. We provide solutions for aggregate

China Mobile Crusher Conveyor manufacturers Select 2023 high quality Mobile Crusher Conveyor products in best price from certified Chinese Crusher Machine, Mobile

2021413 This stone investigates the long-term production scheduling and the crusher relocation plan of open-pit mines using a semi-mobile IPCC system and high-angle conveyor.

\n \n PDF Petri net modelling of industrial processes from a \n. nbsp 0183 32 System related engineering tasks are often conducted using process models In this context it is essential that these models do not contain structural or terminological inconsistenciesProduction line balancing by Pnbsp 0183 32 Although the conveyor belt was first used by meat factories

The conveyor elevation system has a substantial ground clearance, which assists the crusher’s outstanding manoeuvrability at all crushing sites. Maximum reliability and minimal maintenance In addition to the spacious gap of 530 mm between the jaw crusher and the conveyor belt, the crusher’s outlet area is protected by covers.

Crushing and conveying. ABB has decades of experience with electrical equipment and automating systems in open-pit mining and material handling, with more than 700 kilometers of conveyors and several crushers engineered and commissioned. Today, deeper deposits and lower material quality require more intensive efforts to extract commodities.

202154 mathematical framework for optimizing the conveyor and crusher locations under semi-mobile IPCC systems that maximize the NPV, while considering the material handling and crushing station

Features of Mobile Crusher Conveyor Belt. These belts can be made from M, DIN-Y, N and XCG rubber compounds for mobile crushers, screens and radial stackers and may be supplied with either natural flat rubber, C5 ~ C25, multi-V or other more complex profiles. We also carry various sized belts for these systems from 300mm through to 2200mm or

20151223 In over 50 installations throughout the world, loader-mobile crusher-belt conveyor systems have proved to be cost-effective. The decision whether to use a mobile crusher unit at the open pit or a conventional fixed crusher installation located elsewhere at the mine site must be made during the planning phase of the mining project. The decision

2016224 System utilization % 78 Run time/prod. time Average hours per shift 6.24 Hours per day/3 3 shifts, hours 18.72 Utilization % x 24 hrs System availability % 72 Runtime hours/total time available NOMINAL OPERATING RATE 4,808 90,000/hours in 3 shifts (Average tonnes per hour) Conveyor design rate tph 5,769 (1.20 * operating rate)

20231015 much easier to operate the conveyor lifter. The mobile crusher uses a new interlock system that controls the travel operation, to prevent the conveyor from being dragged or colliding with the ground depending on the conveyor’s position. Sprinkler Nozzle Feed opening: 1065 mm x 550 mm 42" x 22" 2800 mm (9'2") KCJ4222 Jaw Mode A:

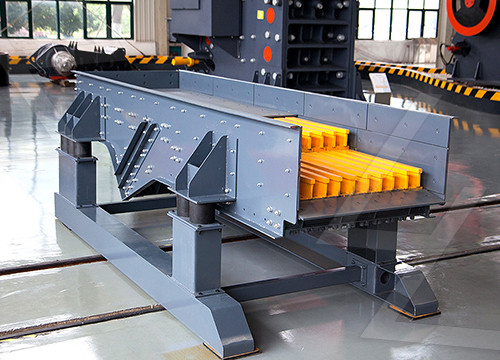

202327 A Mobile Crushing Plant is a piece of machinery that is used to crush rocks and other hard materials for a specific purpose. It typically includes a vibrating feeder, a jaw crusher, a cone crusher

In a mobile crusher (1) for fragmented material, comprising a frame (20) provided with at least one chassis (21, 22), a crusher (6) which is disposed on the frame (20) and has a discharge opening for crushed material, a load delivery device (2) for loading the crusher (6) mounted on the frame (20) and an unloading device (3), the unloading device (3) is

2020114 Conveyor length plays a large part in determining the most optimal belt design: A stationary crusher can support longer conveyor systems due to the site’s permanent structure and immobility of the stationary crusher units. A mobile unit will have much shorter runs and see increased cycles and revolutions on the conveyor belts.

20221121 Conveyor system The conveyor system transports the crushed material to the dumping site or the processing plant. Conveyors can be designed stationary, relocatable or shiftable for bench and dumping operations. In particular open pit applications including high-incline and curved conveyor systems can be offered by thyssenkrupp in conjunction

20151223 system, because the blasted material, concerning block size, cannot be conveyed without prepara-tion. The key to cost reduction is an in pit crushing system (IPCS), a combination of track mounted mobile crusher, with mobile and fixed conveyor belts. In the following the authors will just refer to

Contact. The jaw crusher MOBICAT MC 110 EVO2 is used for the precrushing of almost all natural rock and in recycling. Compact dimensions, efficient prescreening, simple operation via SPECTIVE as well as impressive production output characterize the efficient key player. Continuous Feed System (CFS) for optimal crusher feeding.

RSM menjual spareparts conveyor dan aksesoris conveyor lainnya. Pertambangan batu menempati posisi cukup strategis di industri unggulan nusantara saat ini. Sebab itu, permintaan untuk jasa fabrikasi crusher conveyor juga semakin meningkat. Bukan sembarang conveyor, fabrikasi crusher conveyor yang berfungsi mengantarkan hasil

2017726 conveying system, the system location should also be optimized to reduce operating costs. The crusher site dictates the haulage length for both parts (conveyor and truck) of an IPCC system and the haulage system capacity. The capital and operating costs of an IPCC system thus depend strongly on the crusher locations (Roumpos et al., 2014

2023118 Warehouse Automation Updated January 18th, 2023. A conveyor system is a fast and efficient mechanical handling apparatus for automatically transporting loads and materials within an area. This system minimizes human error, lowers workplace risks and reduces labor costs — among other benefits. They are useful in helping to move bulky or

2020131 The conveyor elevation system secures sufficient ground clearance, which provides the crusher with outstanding maneuverability at any crushing site. In addition, improved configuration and location of the guide handle makes it much easier to operate the conveyor lifter. The mobile crusher uses a new interlock system that controls

Our crawler mobile crusher and screener machines are highly maneuverable, can be applied to a variety of terrains, and can fully meet the mobile screening requirements of customers. Conveyor System Save Shipping Time And Costs. The conveying equipment mainly includes the main conveyor, the side conveyor, the return conveyor and the

20231012 If the crusher is to be fed directly by a conveyor: All dangerous parts of machinery should be suitably guarded. Failure to replace guards (on crushers and conveyors) after cleaning or maintenance work is a major cause of injury on these machines. Fig. 2 Excavator feeding mobile stone crusher. Blocked crushers Causes

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين