1. To control the quality of coal being sent to the burners located on the furnace walls. The word quality here means the temperature and fineness of the PF. The set temperature

20161115 Biomass conversion and co-combustion in coal fired power stations offers a low cost and high impact solution to reducing carbon emissions. However technical

The proximate and elemental analysis of the three coals is detailed in Table 1, with their mercury, higher heating value (HHV), and vitrinite reflectance are given in Table 2. Valle

202091 In order to realize the fault diagnosis of coal mill with low cost and high accuracy, a fault diagnosis method of coal mill system based on the simulated typical

202138 Coke cost. 200 $/ton. Industrial coal cost. 100 $/ton. H2-SMR no CCS. 1.275 (1.05-1.5) [(Damen et al., 2007)] $/kg. H2-SMR 53% CCS (blue) 1.545 (1.32-1.77) [(Damen et al., 2007)] $/kg. H2-SMR 89%

2016925 The Lurgi process which utilizes a fixed bed, high pressure gasifier, can utilize low cost coal as feedstock. Liquefaction and methane-from-coal production costs are listed in chart form. Read more

2021915 Here are the five largest coal mines by production in China, according to GlobalData’s mining database. 1. Daliuta-Huojitu Mine. The Daliuta-Huojitu Mine is a

2020820 This study investigated ultra-fine coal grinding performance of four low- to moderate-cost grinding media in a laboratory stirred mill.

200171 Low-cost sawdust waste and light fractions of municipal wastes were selected as key biomass wastes to be combined with biosolids and coal fines to produce

202138 It can allow non-coking coal and low-cost iron ores (outside BF quality range) to produce iron with 20% less carbon footprint [(Quader et al., 2016)]. Commercial level successfulness for this technology is

2017427 So the first two articles in the” Understanding the Business of Coal” series were 1) high moisture low heating values coal may be lower cost due to coal geology, 2) pipe velocity and ash

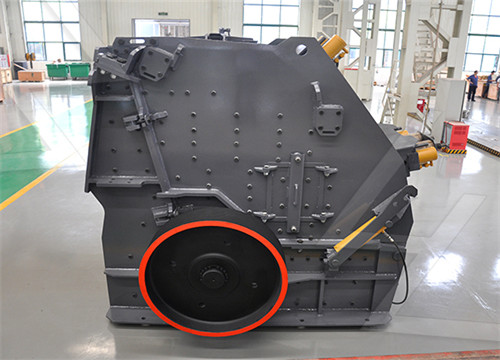

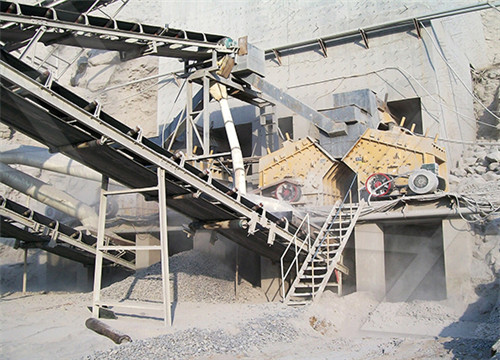

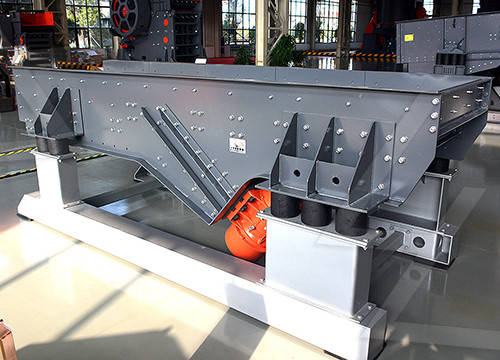

The pulverized coal is taken out of the mill by hot air. Advantages. Compared with the vertical roller mill, the advantages of air-swept ball mill are strong adaptability to raw coal quality, simple operation and low investment cost; the disadvantages are high power consumption and high noise. Vertical Roller Mill

What is mpl Low Cost Coal Grinding Mill, Raymond Coal Grinding Mill, MTW grinding mill plant manufacturerssuppliers on Video Channel of Made-in-China.

201999 Operating costs for flat-rolled mini-mill producers have dropped in 2019 as weaker steel markets have pulled down metallics prices. This has meant that operating costs for mini-mills are now in line with integrated producers in the USA. However, the current cost level is not expected to be maintained. US mini-mills are typically higher cost.

202047 Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants. The traditional data-driven fault diagnosis methods often result in low fault recognition rate or even misjudgment due to the imbalance between fault data samples and normal data samples. In order to obtain massive fault sample data

201711 The prospect of utilizing a low-cost coal as a feedstock for a value-added anode coke, was a driver in this effort particularly if the need for a hot filtration step of the coal digest could be omitted. Using approximate current (1 July 2016) prices, the cost of a Central Appalachian steam coal would be on the order of $41/t.

2016329 low carbon technologies favour modern minimills, hence social and regional adjustments by integrated mills are also likely, leading to resistance to change. • Energy production, transformation and transportation require large to smelt iron ore in a modern BF/BOF integrated mill. + In addition, capital cost per tonne of capacity is 60 to

2020812 Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size. Rotary kilns then use the powders as fuel burners. The VCM has a housing section equipped with a lining

The pulverized coal is taken out of the mill by hot air. Advantages. Compared with the vertical roller mill, the advantages of air-swept ball mill are strong adaptability to raw coal quality, simple operation and low investment cost; the disadvantages are high power consumption and high noise. Vertical Roller Mill

202181 3.10 The low lubricating oil pressur e of the coal mill caused the trip of the coal mill Cause analysis : ( 1 ) Insufficient output of oil pump. ( 2 ) The filter screen is seriously

What is mpl Low Cost Coal Grinding Mill, Raymond Coal Grinding Mill, MTW grinding mill plant manufacturerssuppliers on Video Channel of Made-in-China.

202047 Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants. The traditional data-driven fault diagnosis methods often result in low fault recognition rate or even misjudgment due to the imbalance between fault data samples and normal data samples. In order to obtain massive fault sample data

2016329 low carbon technologies favour modern minimills, hence social and regional adjustments by integrated mills are also likely, leading to resistance to change. • Energy production, transformation and transportation require large to smelt iron ore in a modern BF/BOF integrated mill. + In addition, capital cost per tonne of capacity is 60 to

2020812 Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size. Rotary kilns then use the powders as fuel burners. The VCM has a housing section equipped with a lining

2021114 (BCURA-roll) mill—high stress wear tester, the dry-sand rubber wheel low stress scratch- ing abrasion tester, the Yancey, Geer and Pr ice (YGP) abrasion te ster, the hammer impact Figure 1.

2022824 In order to achieve China’s ambitious carbon neutrality target, coal industry should play a key role in mitigating its carbon emission and ensuring energy supply. Therefore, it is urgent for this coal industry to realize its transition toward low carbon development. This study investigates the status and policy options of China’s coal

202211 The improvement of energy efficiency has been considered the most cost-effective way to reduce energy consumption and CO 2 emissions (Worrell et al., 2009), and according to the EU Energy Efficiency Directive (EED), energy efficiency needs to be prioritized to meet the new EU 2030 climate target (European Commission,

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين