2022531 Simulation experiment. To testify the reliability and availabilityof proposed approach in this , GA-IFCM-IDHGF is used to evaluate the current running status of coal mill by giving a mark, and the main evaluation index RMSE, FDR and FAR are

2020812 Ultimately, the energetic efficiency of coal mill has been investigated and performance value has been found to be a maximum value of 96.2%. Air-flue gas cycle of coal-fired power plant. PA...

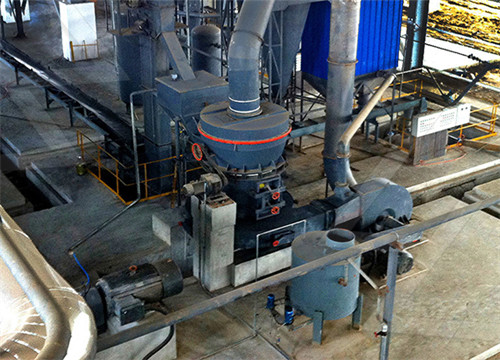

2023214 ABSTRACT. This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coal-fired power plant. In a power plant, the

2022531 The performance of the proposed performance assessment method is verified through its application in a self-defined step fault system and an actual industrial

202042 PDF : Fuel and firing system purposely to deliver light fuel oil or coal as one of the primary elements of fuel in an ideal condition for

202161 A coal mining bootstrapped Malmquist environmental performance index is proposed. • Environmental performance change analysis in biased estimates is

This stone analyses the influence factors of coal enterprise competition strategy, based on which the stone constructs the performance evaluation index system of the coal

199781 This stone describes the analysis results of the dynamic characteristics of coal grinding mills used in a large coal-fired power generation unit. The aim of the work is

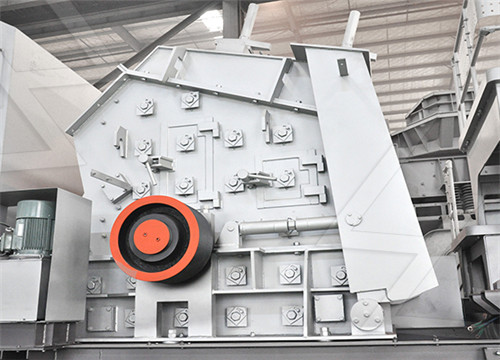

Coal Mill. Coal mill pulverizes coal into a suitable particle size for injecting into a furnace. From: Advances in Power Boilers, 2021. Related terms: Energy Engineering; Boiler;

201911 PDF This stone analyzes the effects of coal grindability and its characteristics on the grinding capacity and power consumption for beater wheel mill Find, read and cite all the research...

2021114 Ball-race mills and Loesche roller mills were used. Three types of interactions between mineral particles and grinding components, Fn-normal force, Ft-tangential force, m-mass, v-speed.

2012131 Zuo et al. [20] showed that the relationship between coal size reduction and energy input is a nonlinear curve, so it is difficult to represent coal grindability with a single numerical value

201681 Thus, the classification performance will influence the ignition, burning, and burnout of the coal particle, and NOx formation in the furnace as well [1–4]. The first generation of the coal mill classifier used static guide vanes to produce a swirling flow to classify the particles by centrifugal force [5–10].

201471 Coal pulverizer manufacturers provide sets of curves linking actual performance of the mill with coal with different properties such as HGI, moisture content % and feed particle top size. These curves enable results of a test on a particular coal to be referenced back to the standard conditions to monitor the performance of the pulverizer

2022531 The index layer represents all operation variables of coal mill, which has important impact on performance evaluation of coal mill. The traditional analytic hierarchy process (APH) method is adopted to compare the importance among variables in the system through Table 1,which would be considerably effective, when all variables would not

202219 The four elements (man, machine, environment, and management) in the coal mine and their synthesis are calculated and analyzed by using the Matlab tool and the BP neural network program. The predicted value of the personnel intrinsic safety value is (0.86–0.85). The intrinsic safety value of the equipment is (0.93, 0.95).

201911 mill power consumption, an integrated coal mill performance 170490 VOLUME 7, 2019 X. Hong et al. : Abnormal Condition Monitoring and Diagnosis for Coal Mills Based on SVR

2014104 The most commonly used measurement of coal grindability is the Hardgrove Grindability Index (HGI) however, many solid fuels do not exhibit the grinding performance predicted by this index.

20141111 Standard grindability test for ring-roller/ball mill is required for biomass Bond Index test can be used for biomass for analysing grinding performance of biomass in tube and ball mill Matching P 80 to classifier particle size critical in optimising mill performance Pre-densified particle size of pellets has large impact on

2020225 For the evaluation of mill operation performance with high-moisture coal, three different coals with moisture contents of 45%, 50% and 55% were applied, and drying capacity and mill operation stability were verified in the test. For the evaluation of mill operating conditions resulting from varying humidity at the mill

20161115 La Loma coal was included in the study to provide a reference coal against which the performance of the biomasses in coal mills could be compared. La Loma has a HGI value of 46, a standard HGI for coals burnt in UK coal fired power stations [39]. Download : Download high-res image (817KB) Download : Download full-size image; Fig. 1.

20131127 Properties of Coal • Coal properties are evaluated by different methods. • The most commonly used methods are Proximate and Ultimate analysis of the coal. • Proximate analysis gives the Moisture, Ash and Volatile matter, while the Fixed Carbon is found by difference. • Ultimate Analysis gives the elemental composition of the coal. •

2022123 There are usually four kinds of VRMs in the cement production line, including raw meal mill, coal mill, Clinker Mill and cement mill, and the vertical mill occupies a large energy consumption unit.

2021215 The ball tube mill requires less mass flow rate of primary air and raw coal per MW of power produced than the bowl mill. It contains larger mass of raw and pulverized coal but less grinding heat

201958 Abstract The correlations of the composition, structure, and properties of coal from Ukraine, Russia, Canada, Australia, the Czech Republic, Poland, and Indonesia with its Hardgrove grindability index are investigated. It is found that the Hardgrove grindability increases with increase in total carbon content Cdaf and aromatic carbon

2022726 Aiming at the typical faults in the coal mills operation process, the kernel extreme learning machine diagnosis model based on variational model feature extraction and kernel principal component

201181 Pulverizers 101: Part I. Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a defined raw coal size

201781 In a coal-fired power plant, one of the main equipment is the coal mill, whose effectiveness influences mainly the whole power plant performance (Shah, Vuthaluru, and Vuthaluru 2009).

2013126 Nomenclature-Bowl Mills 583 XRS / 803 XRP Bowl mills 58,80 stands for bowl diameter in inches If the number is even then its shallow bowl mill. If the number is odd then its deep bowl mill 3 number of rollers three nos. X frequency of power supply 50 cycles.In USA ’x’ means 60 cycles. R- Raymond, name of the inventor

2023523 Goossens et al. 1 combined the values of 60 sensors to construct a global damage index for the structure and implemented the security alert by setting the damage monitoring threshold. Lei et al. 2 reviewed the four processes of remaining useful life (RUL) prediction for mechanical devices: data acquisition, HI construction, health stage division,

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين