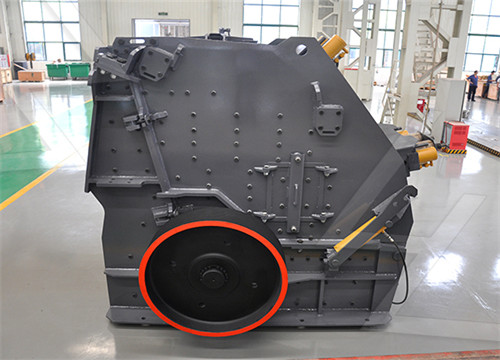

The mechanism of movement of rocks down the crusher chamber determines the capacity of jaw crushers. The movement can be visualised as a succession of wedges (jaw angles)

2023621 Jaw crusher is crushing equipment that works with two jaw plates, one fixed and the other movable. The movable jaw plate approaches the fixed jaw plate

202315 The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between

2022222 The movement of the jaw can be quite small, since complete crushing is not performed in one stroke. The inertia required to crush the material is provided by a

2019328 Breaking down large glasses Crushing other hard materials In single-toggle jaw crushers, the moving crusher operates in an elliptical pattern while in double-toggle jaw crushers, a pendulum motion

20221224 Yang established a parametric model of a jaw crusher using the ANSYS Parametric Design Language (APDL) and optimized the design with the minimum weight of a movable jaw as the objective

9.3.1.1 Jaw Crusher Operating Principles. Fixed and movable jaw plates are the two main components. A motor-driven eccentric shaft through suitable hardware makes the

2022920 Abstract. This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for

202315 The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jaws. The crushing process takes place when the feed material between the two jaws is compressed and crushed by

March 28, 2019 / in News. A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks. The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily

201611 The ore is to be broken down in a jaw crusher to pass through a 11.5 cm screen. The undersize is scalped before feeding to the jaw crusher. Assuming the maximum feed rate is maintained at 30 t/h and the shapes of feed and product are the same and the crusher set is 10 cm, estimate the size of jaw crusher required and the production rate.

201611 A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h. The largest size of the run-of-mine ore was 1000 mm. The required product size was less than 162 mm. Manufacturer’s data indicated that the nearest size of gyratory crusher would be 1370 mm × 1880 mm with a cone angle of 18°.

2023621 The movable jaw plate approaches the fixed jaw plate periodically to realize the functions of crushing, splitting, breaking, and impacting, thus to coarsely or mediumly crush materials with various hardness. It was invented by American E.W. Black in the 1850s. The specification of jaw crusher is expressed by the feed port width B and

2017630 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine

2021218 Jaw crushers typically use the principles of compression and friction to break materials down. They’re extremely powerful equipment that should be used with the utmost care. Jaw crushers are so powerful that they’ve earned the moniker “rock breakers” because of their brute force. All jaw crushers will have one fixed jaw and a moving one.

20231019 5 5.2 Gyratory crusher : A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel

2022114 Jaw crushers are widely used in mining, smelting, building materials industry, highways, railways, water conservancy and chemical industries and many other sectors, crushing various materials with compressive strength within 320 MPa.. Working Principle. Jaw crusher mainly consists of a frame, an eccentric shaft, a large pulley, a

The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone. The ore is discharged through the smaller bottom output hole of the cone. While the cone does not move, an interior crushing movement is created by a revolving shaft on a vertical rod.

201965 than the opposing metal piece. Jaw crusher movement is obtained by using a pivot point located at one end of the “swing jaw”, and an eccentric motion located at the opposite end. [1,27]. Fig -1: Schematic of Jaw Crusher 1.2 Working Principle of Jaw Crusher: The working principal of Jaw Crusher is based on modern

20231024 Introduction: Jaw crusher is a robust size reduction equipment designed to reduce large solid materials into smaller particles, widely used in the quarrying, metallurgical and allied industries. Jaw

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

Key Features. Outlines the theory and practice in the design of flow sheets and operation of an integrated mineral processing plant. Introduces the basic magnetism, electrostatic, conductivity, and dielectrophoresis properties of minerals and related separation techniques.

201734 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the

2023320 The eccentric shaft is a critical component of the jaw crusher because it is responsible for the movement of the jaws. It is usually made of high-grade steel and is supported by bearings at both ends.

201491 Then the total efficiency of a jaw crusher can be defined using Eq. (6) as: (A.25) η Power Total = Δ S Power P Jaw Crusher / η Limit = η Power / η Limit. In the Rose and English [4], [5] model the moment the SGA starts to

The working principle of jaw crushers is based on the reciprocating movement of the swing jaw that compresses and crushes the ore between itself and the fixed jaw Compression of ore between the jaws. Compression is repeated several times until the rock leaves the crusher’s discharge end. Jaw crushers with a small gape are used to crush

202395 Thanks to synchronous movement of crusher frame, motor chassis and motor. Working principle of JC Series Jaw Crusher The motor drives belt and pulley. The movable jaw swings up and down before and after through the eccentric shaft. Iron ore processing. Prodcut Knowledge. SMG200EC hydraulic cone crusher was delivered to

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين