2022728 handbook meets the long felt need of the lime productionprocessing and fills up the existing knowledgetechnology gaps in the sector. The book composed of

201591 Finally, this section explains costs of production and economies of scale. 2.1 PRODUCTION PROCESS, INPUTS, AND OUTPUTS The production of lime begins with

2021121 Diethelm Walter b,Bernd Epple a Add to Mendeley https://doi/10.1016/j.ijggc.2021.103430 Get rights and content • Process modelling of

2021121 The production of lime is achieved through the calcination of limestone (mainly CaCO 3) at temperatures between 900 and 1200 °C. This process is highly

201767 PDF Long-term fertilizer response studies have shown a significant increase in growth and yield of acid lime with applications of 400 g and 800 g N Find, read and cite all the research you...

The lime production process is energy intensive and results in CO 2 emissions from both mineralogical transformation process and energy used. The production of one tonne of

2022101 Descriptions of the lime (and slaked lime) production processes and configurations . • Overview of carbon capture technologies available for the lime industry.

202361 This process allows the capture of carbon dioxide by condensing the steam from the exhaust gases which avoids the need for the energy intensive step of separation

2014108 Oxyfuel technology applied to lime production would cause several major changes to the lime plant. The implications of all these changes, e.g., air separation unit, new piping, and fans for gas

2021121 1. Introduction. Lime (CaO) is an important product used in different sectors of the industry as well as in agriculture. The production of lime is achieved through the calcination of limestone (mainly CaCO 3) at temperatures between 900 and 1200 °C.This process is highly endothermic and requires the combustion of fuels such as gas

2021625 11.17 Lime Manufacturing 11.17.1 Process Description 1-5 Lime is the high-temperature product of the calcination of limestone. Although limestone deposits are found in every state, only a small portion is pure enough for industrial lime manufacturing. To be classified as limestone, the rock must contain at least 50 percent calcium carbonate.

2021121 Introduction. Lime (CaO) is an important product used in different sectors of the industry as well as in agriculture. The production of lime is achieved through the calcination of limestone (mainly CaCO 3) at temperatures between 900 and 1200 °C.This process is highly endothermic and requires the combustion of fuels such as gas oil, coal,

202111 This study provided preliminary evidence that, based on the current EU market, on average 23–33% of lime process emissions are carbonated during the use phase. Carbonation over time is also

2020728 In typical cement manufacturing process, 60% of CO 2 emissions are due to the transformation of limestone to lime (the calcination process) and rest 40% is due to fuel combustion in pyro processing. The air is used as an oxidizing agent content in industrial combustion processes that has maximum nitrogen component (78–79%) by

197753 a lime manufacturing plant is given in Figure 11.17-1. Note that some operations shown may not be performed in all plants. The heart of a lime plant is the kiln. The prevalent type of kiln is the rotary kiln, accounting for about 90 percent of all lime production in the United States. This kiln is a long, cylindrical, slightly inclined

2021625 represented less than 2 percent oftotal U.S. lime production in 1999 (Miller, 1999a). Lime producers can be broadly characterized as captive and commercial. Captive lime producers produce lime that is used by other operations within the same company, frequently at the same plant location. The markets associated with captive lime production

2014108 The generic lime kiln model is simplified from a more extensive model of an operational lime plant of Nordkalk Oy. The full plant model has been validated against the operational data. The validated full plant model was reduced to a more generic rotary kiln lime process setup and equipped with a flue gas circulation option.

197753 a lime manufacturing plant is given in Figure 11.17-1. Note that some operations shown may not be performed in all plants. The heart of a lime plant is the kiln. The prevalent type of kiln is the rotary kiln, accounting for about 90 percent of all lime production in the United States. This kiln is a long, cylindrical, slightly inclined

201781 The annual world lime production amounts to approximately 350 million tons. Integrated iron and steel works operate their own lime kilns in captive plants. These lime kilns are often fired with coke oven gas, converter gas or mixed gas and these gases contain almost no sulphur. €“000 17 6.2 Influences related to material property

201874 The EU28 total lime demand in 2017 was estimated at about 20 million tons, out of which about 40% are consumed in the iron and steel industry. Steel remains the major consumer after environment and

2021121 Lime reagent utilization efficiency can be defined as the mass percentage of the lime reagent participating in the target reaction(s). Utilization efficiency is not generally explicitly determined in gold processing operations, although it is an important consideration when comparing lime reagents and can readily be determined under laboratory

201591 characterizing the lime manufacturing industry. This section describes all steps of the production process, emission controls, and inputs into this process. In addition, characterizing the supply side of the industry involves describing various types of lime products, by-products of the production process, and input substitution possibilities

Governments and heavy-use lime industries are beginning to acknowledge the significant environmental problems associated with traditional kilns and introduce incentives to clean up the manufacturing process. Establishing the funding and partnerships needed for sustainable full-scale calciner plants for lime is a challenge.

1. Introduction. The process emissions of lime production, i.e. the CO 2 released during limestone calcination excluding that released from the combustion of fossil fuels, are estimated to account for about 1% of the global anthropogenic CO 2 emissions excluding those associated to land use change [Citation 1].Anthropogenic CO 2 emissions are the

2021822 At the same time, compared with conventional process, the new MURC process saves the consumption of steel material about 2.3 kg/t and consumption of lime 11.2 kg/t averagely. Read more Article

2022513 Decarbonisation in the lime sector. 13 May 2022. This week Air Liquide partnered Lhoist for the operation of a carbon capture facility at Lhoist's Rety lime plant in France. ICR looks at how the lime sector has set about decarbonising and where its major pilot projects are starting up. The Lhoist project in the Hauts-de-France region will

The causticizing and lime kiln load increases 20%, which can adversely affect the mill’s capacity for pulp production. The increased causticizing load can, however, be eliminated by including a titanate-based cyclic process called direct causticization technology ( Chen and van Heiningen, 2006; Sinquefield et al., 2010; Naqvi et al., 2012a, b ).

202034 ii Cement and Lime Manufacturing Industries At present, about 78% of Europe's cement production is from dry process kilns, a further 16% of production is accounted for by semi-dry and semi-wet process kilns, with the remainder of European production, about 6%, coming from wet process kilns. The wet process kilns

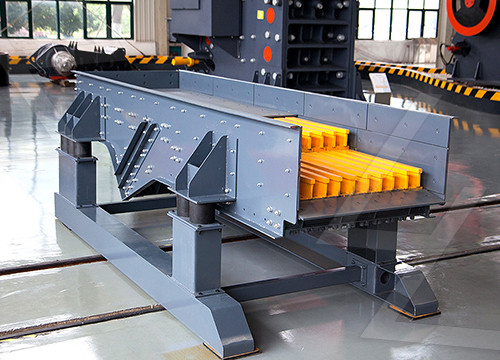

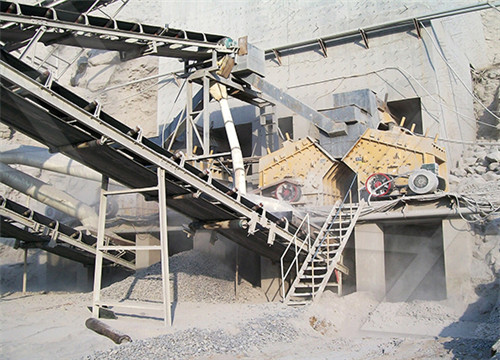

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين