202028 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle

2016224 Design criteria can be calculated from a simple spreadsheet as shown in Table 2. Mine haul-truck capacity is an important factor at primary crusher installations,

202327 From F and P quarry’s crushing plant operation report for the month of September, 2018, the computed (Table 1) average working hours (w) is. 5.2 hrs;

2008827 The optimization method discussed in this stone utilizes both technical and economic calculations in order to find the most profitable solution. The aim of the

2021624 Whether you need a single crusher, a multi-stage process or a complete plant, we assist you with the right design for the most cost-eff ective crushing process.

2021813 implementation in for example Plant Designer etc. III Figure 6: The results from the production cost calculations.....18 Figure 7: Payroll distribution function

2017823 design of a control model utilising two crusher variables and a self-tuning control algorithm. In this research work, a process model describing the dynamic operation

200961 In this , we present a case study of a typical crushing plant, with the goal of reducing the number of crusher while keeping the plant capacity and quality. By

2015513 Layout of a four-stage crushing plant for ballast production. production costs. Prediction of crusher performance has been focused on, since crushing is a two main calculation models are

2017828 calculate the cost per unit throughput (in this case, unit volume or weight crushed rock) from the formula C-- R. ~P._P_ where R is the yearly unning cost without

2023110 To calculate the cost per ton, you will need to divide the total cost of the crushing and screening operation by the number of tons of stone that were processed. For example, if the total cost was

20221221 To calculate the production cost, you will need to first determine the total cost of the raw materials, labor, and energy. Then, divide this total cost by the number of units of product produced

2017823 plant designed to produce copper concentrates from oxide, supergene, and sulphide ores. The expected average output of 16.2 tons per hour of copper concentrates has never been attained since plant commissioning. The major bottleneck has been established to be located around the crushing circuit of the Mowana production chain.

2016217 jaw crusher production capacity. Example capacity calculation of a 10″ x 20″ (250 mm x 500 mm): Pp = 2800 (2.8 SG) For any particular aggregate production plant, it is advisable to make preliminary determinations of the types of crushers needed. If most of the feed is coarse and stage crushing is required, primary crushers that meet the

2021624 Whether you need a single crusher, a multi-stage process or a complete plant, we assist you with the right design for the most cost-eff ective crushing process. We are the world’s leading supplier of both unit machines and complete aggregates processing systems. Comprehensive process solutions Your system may involve a whole series of

202319 50-100tph Hard-stone Crushing Plant There are several ways to calculate the production capacity of a stone crusher, but the following steps are the most commonly used: 1.Determine the desired

2022821 The capture of a crushed piece occurs due to the stop located on the roll (see Fig. 1 ); in this case, the condition for formation of a complex stress state in the crushed piece is observed, and the energy consumption is reduced by 39–40% [ 9 ]. Fig. 1. Schematics of the crusher with stops on a roll. Full size image.

2023228 Stone crusher plant design is a crucial factor in the efficient operation of the crushing process. The primary goal of plant design is to achieve the desired product size and capacity while balancing capital and operational costs. A well-designed plant will help minimize production downtime and reduce operating costs while maximizing production

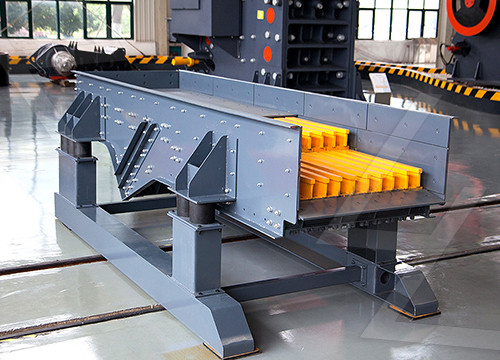

2008827 A production unit is defined as a machine or larger arrangement used to move, store, separate or crush material in the crushing plant. A production unit can be a crusher, screen, feeder, storage bin, stockpile or conveyor. Each production unit is represented by a model, which can be used to predict the performance of the individual unit.

201491 The main reason for this inefficiency is in the random distribution of forces on the particles inside the crusher. With certain simplifications, the theoretical energy efficiency of comminution can be estimated to fall between 5 and 10 % (LegendreZevenhoven, 2014) while the measured energy efficiency in actual comminution testing

2023223 Introduction. An aggregate crushing plant is a machine that processes a wide range of raw materials into high-quality aggregate, which is used in a variety of construction applications such as roads, buildings,

2016310 a) Maximum Feed Opening — 625MM (25 In.) b) Recommended Product Range — 100MM to 19MM (4 In. to ¾ In.) Short Head (Tertiary) Cone Crusher (Refer to Fig. 2): The Short Head Cone crusher is normally applied as a third stage crusher in plants designed for three or four stages of crushers.

implementation in for example Plant Designer etc. III Figure 6: The results from the production cost calculations.....18 Figure 7: Payroll distribution function jaw or a gyratory crusher and screening equipment. The secondary have a single or several cone, VSI, HSI crushers and screening equipment.

2020414 ) Calculate the amount of re-circulating load to the crusher, by referring to the applicable table. Example a) Wi=14 curve selected in above table. b) 5 mm sand required. c) Table A1 indicates a 30% breakage ratio at 5mm. d)Product required at the rate of 100 TPH. e) Total throughput of the crusher = Product TPH (100) x 100 / 30 (%

202327 crushing plant contains a complex mix of sizes from fines to the maximum size the plant can pass and is called crusher run. This is used for constructionfill and is common in South- Africa. 5. Screened out fine material from the secondary crusher is called blinding. Some screens have multiple decks and can screen out several grades of blinding.

202327 compared with other production plants; and the dynamics of quarry operation are with many unknowns that are capable of influencing the utilization of the equipment. 2.0 METHODOLOGY . 2.1 OEE Calculation for Crushing Plant . Crushing plants are used in granite aggregate quarries for processing and classifying crushed granite

Gyratory crushers are principally used in surface-crushing plants. The gyratory crusher (Figure 6.5) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeve.The spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within

20211215 Comminution is a major contributor to the production costs in a mining operation. Therefore, process optimization in comminution can significantly improve cost efficiency. The mine-to-mill concept can be utilized to optimize the comminution chain from blasting to grinding. In order to evaluate the mill performance of the ore from a specific

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين