Controlling and minimizing exposure to silica dust requires proper wet dust suppression for rock crushers. Because water has a relatively high surface tension (72 dynes per cm), it alone cannot penetrate crushed material that releases silica dust.

201086 Water spray dust control measures are effective at reducing levels of respirable crystalline silica dust. Studies have reported reductions in the range of 60% to

Wet dust suppression systems can cost from $15,000, for small portable rock crushers, to $75,000, for large stationary aggregate plants. The average installed cost of a system for

Spray nozzle on top, underneath the crusher, and on the outlet ensure that the dust is contained within the crusher box. Water keeps the dust down.

2 Wet dust suppression systems have been shown to significantly remove and reduce respirable (breathable) dust, and implementing some

Our ever-evolving offering for mining and construction covers crushing, screening, breaking, demolition, and service solutions designed to increase productivity and boost your

2015910 with the diameter of the rock. The suppressive effect of the moisture depends on both the absolute mass water content and the size of the rock product.

Stationary crushersscreens. We are your long-term partner providing safe and sustainable solutions to optimize productivity through proven expertise in stationary crushingscreening. Our crushing and screening

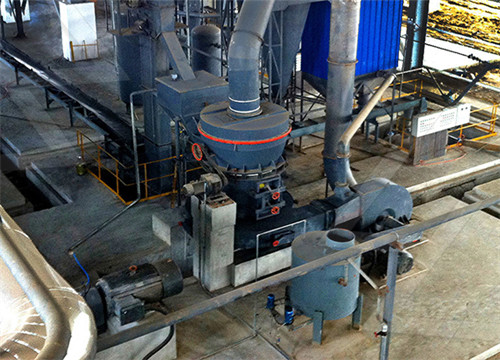

2021724 Explore water-based sprinkler systems and suppression solutions for enhanced air quality and worker health. One way to mitigate dust is by using sprinkler

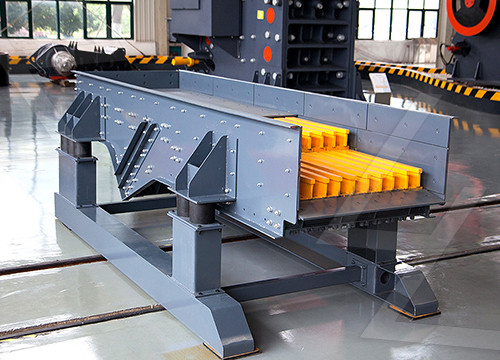

Dust control for screening systems is similar to that for crushers, although wet systems are generally not used due to blanking of the screen openings by the wet material. Screens should be totally enclosed, and water

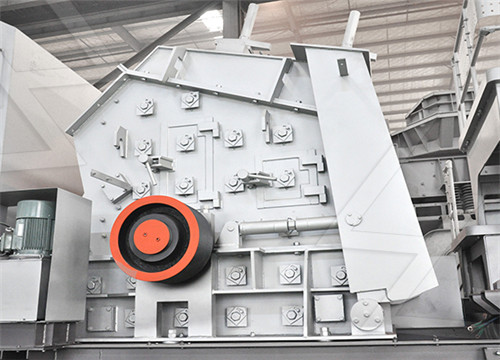

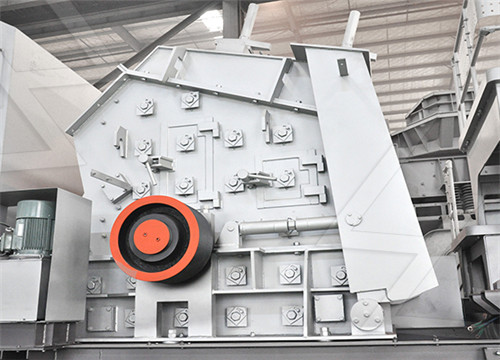

20231030 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as

201086 of the initial application if a high enough volume of water is applied to adhere to larger rock particles. Basic systems without pressurization and chemical additives are effective at significantly reducing respirable silica. Water Spray System Design The spray nozzle is the most important component of a water-spray system because it

The Gates’ gyratory crushers were preferred by the mining industry for almost two decades until the turn of the century, circa 1910, when Blake’s jaw crushers saw a resurgence in popularity. The demand for large-mouthed jaw crushers skyrocketed as the industry began to understand their potential as primary crushers in rock quarries.

2021724 Explore water-based sprinkler systems and suppression solutions for enhanced air quality and worker health. One way to mitigate dust is by using sprinkler systems that dampen dust particles with water. Another is by installing dust suppression systems on stone crushers and quarries that suck up unwanted dust from moving materials.

Modular water fog, or spray, system for controlling dust in and around rock crushers; Operating pressure: 100-150 pounds per square inch; Available nozzle flow rates: 1.9, 2.9, 5.7, 11.5, 23.0 and 34.5 gallons per hour (gph) Available pumps and flow rates (at 150 pounds per square inch): ¾ horsepower 270 gallons per hour

Rock Crushers . 2021-8-26 Rock Crushers. The size requirement of the primary rock crusher is a function of grizzly openings, ore chute configuration, required throughput, ore moisture, and other factors. Usually, primary crushers are sized by the ability to accept the largest expected ore fragment.

DUST SUPPRESSION SYSTEM KAVERI Dust Suppression System suppresses dust at source by preventing it.The system utilizes water nozzles that produce fine mist.Ore Crushing Plants. 15 4 2015 This is the testing of the dust suppression system we designed for quarry crusher.A fine mist will remove the bulk of the dust created

20151216 In a hard rock mine, the product from a jaw crusher will tend to be slabby, while the product from a gyratory crusher may tend to be blocky, the latter being easier to convey through transfer points on a conveyor system. Source: Heinz Schober; Impact crushers (rotary or hammer mills) have the capacity for high reduction ratios (up to 40:1),

Contribute to chengxinjia/sbm development by creating an account on GitHub.

MBMM AT A GLANCE. World leader in design and manufacturer of small and medium scale hard rock ore processing and high-performance gravity concentration systems. Unique solutions for value-added benefits to

Wet Screening for mining, aggregate, wastewater, and . Powered by twin electromechanical 2.5 horsepower Super G vibratory 3 G’s of screen surface acceleration. Water and fine solid rubber-lined wash .

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Contact Williams Crusher. Contact us today to discuss your rock crushing application in detail with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher or locate an agent near you. Industry-best rock crushing machines. Reduce particles to your required size.

The greatest advantage of mobile crushers is the flexibility, both tracked and wheeled versions, greatly shoot the trouble of hauling and thus maximise productivity reduces the operation costs. Now, the mobile crusher can replace the stationary crushing system. Flexible capacity and reliability; Designed and engineered with more than a

Stationary crushersscreens. We are your long-term partner providing safe and sustainable solutions to optimize productivity through proven expertise in stationary crushingscreening. Our crushing and screening equipment is engineered for maximum productivity. We offer advanced, proven solutions for any size-reduction and

20231030 Astec designs and manufactures a wide range of quality crushing equipment that is technology-driven and durably-designed for modern crushing operations. Our state-of-the-art machinery is specifically built to accommodate a variety of applications and materials with high productivity and profitability. Our innovative line of jaw crushers,

202064 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations. In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratory-scale cone crusher. Based on several

Discover our durable crushers on our landing page: crushing-technologies. The TITAN® Double-Shaft Hammer Crusher is used for crushing medium-hard rock. For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials. The mammut® crusher is uncomplicated and compact in design, rugged in its construction, extremely powerful

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين