2019124 In 2017, introduced the OK raw mill, which is designed with the same proven technology and modular design as the OK cement mill. ’s modular

2017619 The modular vertical roller mill for grinding cement raw material, cement clinker, and additives with an installed power of up to 12,000 kW was specifically

2021122 At present, the raw material preparation process of new drying-process cement production enterprises mainly includes middle unloading drying tube mill raw

2017812 Loesche Innovative Engineering. For over 100 years the company Loesche has been building vertical roller grinding mills for grinding: Coal. Cement raw

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill’s modular design comes with

2021122 At present, the raw material preparation process of new drying-process cement production enterprises mainly includes middle unloading drying tube mill raw

201541 A raw meal ball mill classification circuit was modelled and simulated. • 23% capacity increase could be achieved in cement throughput when pre-drying compartment

In this , a system integration updated technology for a large-scale raw material vertical roller mill is introduced, which was developed originally by the Tianjin Cement Industry

202111 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials. With the grinding capacity of a vertical roller

2005220 This stone is concerned with the model of a fully air swept ball mill operating in a raw material grinding circuit. For simplicity, the approach assumes that

The third production line of YongDeng Qilianshan Cement Co., Ltd. was updated and put into production in 2010, the raw material mill of which is the TRM53.4 vertical mill. The vertical mill output is 500t/h and the product R 80μm is 12%. The vertical mill system has defects such as a large mill pressure difference and a high system negative

2021122 Retention time in cement grinding which is the time taken by material to attain the required particle size before it reaches the mill outlet, can be reduced by the use of a closed mill grinding

Cement raw material is the mixture of mainly Limestoneother constituent such Iron oxide, Shale etc. having different moisture contain depending on compositiondeposit. We offer the mills with optimized process

2016120 In the surveyed cement plant, three balances are established between input and output material in the raw mill, clinker production, and cement grinding system. 2.48 t, 4.69 t, and 3.41 t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages; waste gases

2021217 3. PROCESSING. Material flow during processing includes: (a) particle size reduction, (b) premixing, (c) mixing, (d) pelleting, and. (e) sacking. Coarse ingredients pass over a permanent magnet which removes tramp metal and then through a hammer mill which reduces particle size to the desired screen analysis.

201691 In contrast, increasing the separator speed from 60 to 80 rpm at a constant grinding pressure results in a reduced raw material production rate from 240,000 kg/h to 230,000 kg/h and which

2017619 The modular vertical roller mill for grinding cement raw material, cement clinker, and additives with an installed power of up to 12,000 kW was specifically designed to meet the demand for increased grinding capacities and optimized maintenance concepts. Today's cement plants can now be designed with the one-mill concept for both raw

201541 1. Introduction. Air-swept raw meal ball mills introduced by the cement mill manufacturers F.L.Smidth ® (Smidth, 2002), Polysius ® (Polysius, 2002) and KHD Humboldt Wedag® are the most commonly used ones.KHD Humboldt Wedag® manufactured fully air-swept raw meal mills which have two compartments used for drying and grinding processes.

2021416 In this theory, new material characteristics have been added: the surface and volumetric density of grinding energy. The thermodynamic theory is a combination of the classical Kick’s theory and

20211110 H. Raw material grinding/drying -13 I. Clinker cooler -14 J. Clinker piles -15 K. Clinker transfer -16 L. Clinker grinding -17 M. Cement silos -18 N. Cement load out -19 O. Raw mill feed belt -24 P. Raw mill weigh hopper -25 Q. Raw mill air seperator -26 R. Finish grinding mill feed belt -27 S. Finish grinding mill weight hopper -28

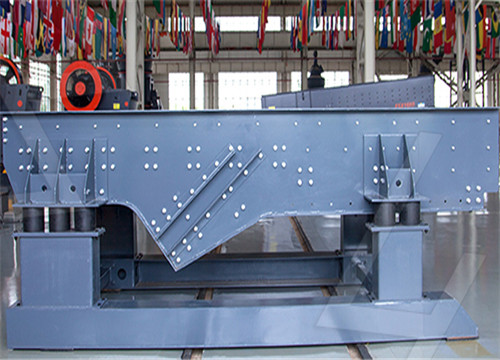

Raw mill is mainly used for grinding cement raw meal in the cement factory production process. It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind various ores and other grindable materials. Cement raw meal is a mixture of various raw materials before cement calcination.

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and more

201261 About 2% of the electricity produced in the whole world is used during the grinding process of raw materials [1]. While total electrical energy consumption for cement production is about 100 kWh/ton of cement, roughly two thirds are used for particle size reduction [2]. About 65% of the total electrical energy used in a cement plant is utilized

cement ball mill. Application: limestone, clay, coal, feldspar, calcite, talc, iron ore, copper, phosphate, graphite, quartz, slag. Capacity: 0.65-615T/H. The cement ball mill usually can be applied to raw meal grinding or cement grinding. Besides, the cement ball mill also can be used for metallurgical, chemical, electric power, other mining

201261 Several grinding methods are available in cement industry depending upon the material to be ground. In cement production process, about 26% of the total electrical power is used in grinding the raw materials. During grinding process, the energy obtained from the rotary burner is consumed. In this study, the first and second law analysis of a

In cement: Grinding. The clinker and the required amount of gypsum are ground to a fine powder in horizontal mills similar to those used for grinding the raw materials. The material may pass straight through the mill (open-circuit grinding), or coarser material may be separated from the Read More; cutlery. In cutlery: Cutlery manufacture

20201116 2.1. Disc Mills. Disc mills are probably the most ancient type of grinding equipment. Their principle of action is as follows: the material passes between two rotating discs, causing friction of particles against the discs and grinding (Figure 1 a).Mills with a variable gap between the discs and discs with notches are used to increase the milling

2017812 vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for dry-grinding the above-mentioned grinding stock. Loesche has developed and built the largest and most

Better grinding performance: Raw mills can grind a wide range of materials, including hard and abrasive materials, which makes them suitable for cement manufacturing. Raw mills are a crucial component of cement manufacturing plants. They play a vital role in grinding raw materials into a consistent raw mix that is transformed into cement in a kiln.

201811 The thermodynamic properties of material flows in the raw mill system for cement production were determined using EES software [10]. The EES code was also employed to investigate the performance of the raw mill system and its parts. The heat loss rate from the raw mill system into the ambient environment was calculated to be

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين