Cement Crusher. Raw materials of the cement plant are mostly from open-pit mines, and the ore usually has a large particle size. In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay,

crusher for cement plant manufacturers/supplier, China crusher for cement plant manufacturerfactory list, find best price in Chinese crusher for cement plant

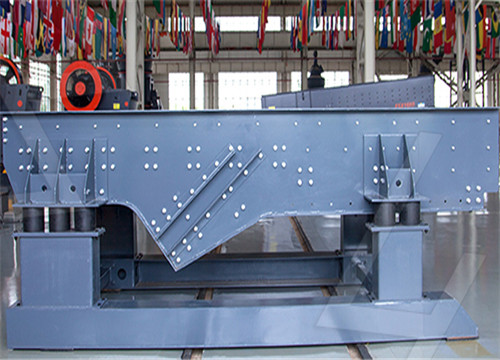

The stone crushing plant manufactured by AGICO mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor,centralized electronic control system, and other equipment.

Raw materials used: maximum 500mm Finished particle size: four kinds of sand between 0-38mm Yield demands: 150 ton per hour Configurations: APG-3895W (vibrating feeder) +

Application: cobble, granite, basalt, iron ore, limestone, quartz stone, diabase, gold ore and copper ore, etc. get price! Cone cement crusher has various classifications. According to types, there are four types: spring

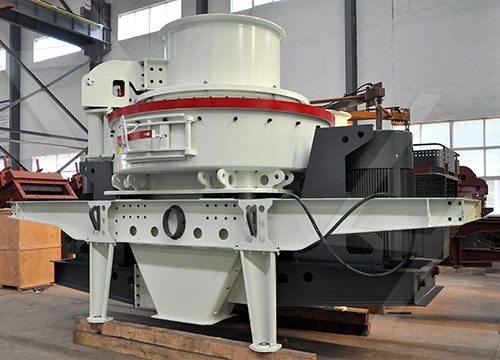

Crusher is a kind of machinery that is widely used in the cement production industry. It is mainly used in the material preparation process to crush the raw materials into proper

As one of the leading stone crusher machinery, concrete mixer machinery, asphalt mixing plant, concrete pump, ore processing equipment manufacturers and suppliers in China,

Punch up your cement production with our efficient impact crushers. Specifically designed for the needs of cement plant operations, our crushing equipment delivers reliable, heavy

2021923 Advantages: large crushing ratio, high efficiency, low energy consumption, less dust, uniform product size, stable operation, low failure rate, and not easy to be crushed. Disadvantages: The structure

Cement crusher. Cement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production line. Before sending

The APC series stone cone crusher machine is usually to crush mid-hard and above mid-hard ores and rocks. It is a popular stone crusher for sale Philippines in manufactured sand production, aggregates production,

\n \n LOESCHE Mills for cement and granulated blast furnace slag \n. furnace slag in roller grinding mills (vertical air swept grinding mills) is a.grinding mill for grinding coal was introduced by LOESCHE in the 1920's.cement clinker and cement raw material mills,and including the use of identical gear drives. Customer service a guarantee of reliable plant

Cement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production line.Before sending it into the raw mill, the cement raw material should be crushed into small sizes by the cement crusher.. The cement raw material can be crushed by many methods including pressing shearing, rolling or

Here are some solutions of stone crusher plants we have provided for Philippines clients. 300-350 t/h Plant For Crushing Limestone; 150 t/h Plant For Concrete Production; 150TPH Stationary Crushing Plant For Producing Concrete. Configuration: APG-3895W (vibrating feeder) + APJ-6090E (jaw crusher) + APC-132C-M (medium crushing

Portable Cone Crushing Plant 50-420 t/h. The portable cone crushing plant consists of a cone crusher, vibrating feeder, conveyor belts, and optionally a screen.; With capacity of about 50-420 t/h, the portable stone crusher machine for sale is used for various applications such as aggregates production, mining operations, construction and demolition,

Horse Power: 205,07 kW. Capacity: 317,52 TPH (tonnes) Serial Number: TRX1161JPOMN99488. The Finlay® J-1160 Primary Mobile Jaw Crusher was designed with the customer and operator in mind. The machine has been designed with increased under jaw clearance and all round preventative maintenance and serviceability access.

Cement Equipment Supplier. AGICO Cement is located in Henan, China. It was founded in 1997 with a registered capital of 81.34 million yuan. It covers an area of 660000m 2 which includes a construction area of 30000 m 2. In 2004, AGICO passed the ISO9001 certification and enjoyed the self-management right of import and export.

2016224 Recirculating water can be used to cool crusher lubrication systems. Project Location A project’s geographical location, topography, geotechnical conditions, remoteness and climate can all affect crusher plant design. Construction costs are generally much greater at high altitudes, in cold climates and at remote sites.

2023228 Portable concrete crusher. A portable stone crusher, a wheeled-mounted crushing machine, is a perfect machine for processing concrete waste because of its strong flexibility. Therefore, it is a mobile crushing plant integrating crushing equipment, conveyor, and power control equipment. It can last for 20,000 hours under difficult

Punch up your cement production with our efficient impact crushers. Specifically designed for the needs of cement plant operations, our crushing equipment delivers reliable, heavy-duty performance. Our range of impact crushers includes hammer and strike-bar impact crushers, as well as dryer crushers and the easy-to-install, long-lasting

20231028 Komplet America was very helpful and made my order of my Komplet K-JC 704 Crusher smooth from order to delivery to us in Hawaii. HTM Contractors is a Diversified service contractor and we invested in a Crusher to help us recycle our own concrete and asphalt we get from our project we then use the recycled material for our

60tph stone crushing plant for recycling construction wastes. APS-1548Y3 vibrating screen. APC-900Y compound cone crusher. APG-0724Z vibrating feeder. APJ-4060E jaw crusher. Max feeding size: 400mm. Finished particle size: screen size is 4800*1500mm. Yield demands: 60 ton per hour. Configurations: APG-0724Z (vibrating feeder) + APJ-4060E (

Generally, the crusher opening would be 125 % of the max. size of stone from mining. Dumpers: Dumpers are heavy duty diesel vehicles. Most commonly used vehicles for transporting run off mine (ROM) stone to crusher feeding hopper plant would be: Self-tipping trucks when mining is manual, for small capacity plants.

Cement Manufacturing Equipment. Cement Crusher. Crusher is a kind of machinery that is widely used in the cement production industry. It is mainly used in the material preparation process to crush the raw materials into proper size particles. AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and

2019531 The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a through-put efficiency of 75.4 %. The crushed products were well graded with 1.89 coefficient of

2023818 The product usually desired is 80-85% minus ( 1/8)" or 1/ (3mm), for this service, 1 2 to 2 HP per TPH is normally required. In cement plants, where hammermills or impactors are used for secondary crushing of cement rock, the feed is approximately 6-10" or (150 250mm) and the product is a nominal (1/2)" or (12mm).

2 A mobile crushing plant is a valuable piece of equipment for countries like India experiencing an infrastructure improvement. With rapid urbanization and an effort to decrease carbon emissions, equipment manufacturers' rise in India is a no-brainer. Some of the best portable stone crusher producers in India are; Aesha Conveyors And Crushing

2019513 The height of the barricade shall be 1.0 metre above the highest point of the stone crusher / conveyor belt. Dairy Units (except Chilling units) dispose the inorganic hazardous waste to TSDF for land filling and organic residue to TSDF for incineration / cement plants for co-processing. The solvent drums shall be kept on concrete platform

Stone crushing plant is a key equipment to crush, screen, and classify the large chunk of raw granite, raw basalt, raw ore, raw quarze, construction waste, and other raw materials into specific sizes, such as 0-5mm, 50-10mm, 10-20mm, 20-30mm, and 30-40mm. Stone crushing plants are widely used for mining, quarry, metallurgical and chemical industries,

400-800 TPH semi-mobile single or double stage coal crushing cater to miningpower plant application for (-) 100 mm or (-) 20 mm sizing as required. 200-500 TPH customized skid plants for Aggregate ,Limestone and Gypsum Crushing. 200 TPH fully mobile track mounted Crusher. For business enquiries, please contact info@lntecc.

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين