2023220 Introduction. Mill vibration has been extensively studied by researchers worldwide. Specifically, researchers have investigated the vibration mechanism and vibration control of rolling mills from three aspects: structural parameters, process parameters,

Mathematical Model of Rolling ProcessDynamic Model of Mill StructureHydraulic Servo System ModelOverview of Coupling Dynamic Model

The Sims method is one of the most widely used methods to describe the plastic deformation of rolled materials. Sims derived the specific rolling force equation [23], which is often applied in hot rolling mills [24]. In this section, based on the Sims rolling force model, a dynamic rolling process model with vibration is proposed.

2022916 The roll system vibration of strip rolling mill is an essential factor

2016119 Rolling mill vibration is a worldwide problem, although it has been found

202141 According to the actual parameters of rolling mill, the rolling mill vibration

2021526 Based on the analysis of the influence of roll vibration on the

2021619 The research results can provide a theoretical reference for further exploration of the coupling vibration of hot rolling mills. Coupled Vibration Characteristics Analysis of Hot Rolling Mill with Structural Gap.

Figure 12. Amplitude–frequency curve of the coupled vibration system of the hot rolling mill with external disturbing force F = 4 × 10 5 N. ( a) Amplitude–frequency curve of horizontal direction; ( b)

2016626 The rolling mill transverse vibration natural frequency was calculated

2005515 1.. IntroductionThe vibrations of the subassemblies of the rolling stands

2023122 Explanation: This Vibration Unit Converter converts the amplitude of single frequency sinosoidal signals between commonly used Acceleration, Velocity and Displacement units such as: Acceleration g's

202062 tandem mill unit of Mobarakeh Steel Company (MSC). Fig. 1 shows a view of this unit. Fig. 1. Two-stand tandem mill unit of Mobarakeh Steel Company Incoming coils of this unit are often 2 mm in thickness. They open up and pass through two 4-high stands two or three times. Usually thicknesses of the strip were reduced by 60 to 90

2020123 parameters of the two mills are given in Table 1. Cold roll product quality Thin, cold rolled steel is a surface-critical product with little tolerance for surface defects. There are two primary sources for steel product surface defects: • Roll surface defects • Chatter vibration Defects on the rolls will directly transfer to the strip.

MeasurementsUnits Displacement (Distance) mils or micrometer, mm Velocity (Speed Rate of change of displcmt) in/sec or mm/sec should be used to measure vibration in mils displacement. Probes should be oriented in two planes 90 ° apart and displacement cannot exceed the shaft to bearing clearance.

2023220 Electric vehicles (EVs) are promising solutions to the problems faced by combustion engine-propelled automobiles. The futuristic transportation system would be majorly catered by battery EVs, hybrid EVs, and fuel cell EVs with a different combination of energy sources that could successfully meet the requirements of different categories of

2021527 Purpose Vibration is a major issue in turbomachines which causes damage to them and leads to reduction in life and efficiency. This stone reviews various methods to measure the amount of vibration in various turbomachines and also discusses various reasons for the same. This will significantly assist in articulating these vibrations.

2021125 4.3 Housing or shaft measurements The vibrations of a gear unit can be measured in two ways, i.e. on the housing (casing) or relative to the shafts. Housing vibration measurements are preferred for gear units operating with rolling element bearings when the clearance in such bearings is small and little relative movement normally occurs

2014318 This technical article explains the concepts and methods of machinery vibration limits and dynamic structural response, with examples and case studies. It covers the sources and effects of vibration, the standards and criteria for acceptable levels, and the techniques and tools for analysis and design. The article is intended for engineers and

201924 Vibration measurement is an effective, non-intrusive method to monitor machine condition during start-ups, shutdowns and normal operation. Vibration analysis is used primarily on rotating equipment such as steam and gas turbines, pumps, motors, compressors, stone machines, rolling mills, machine tools and gearboxes. Vibration

2020123 parameters of the two mills are given in Table 1. Cold roll product quality Thin, cold rolled steel is a surface-critical product with little tolerance for surface defects. There are two primary sources for steel product surface defects: • Roll surface defects • Chatter vibration Defects on the rolls will directly transfer to the strip.

MeasurementsUnits Displacement (Distance) mils or micrometer, mm Velocity (Speed Rate of change of displcmt) in/sec or mm/sec should be used to measure vibration in mils displacement. Probes should be oriented in two planes 90 ° apart and displacement cannot exceed the shaft to bearing clearance.

2021527 Purpose Vibration is a major issue in turbomachines which causes damage to them and leads to reduction in life and efficiency. This stone reviews various methods to measure the amount of vibration in various turbomachines and also discusses various reasons for the same. This will significantly assist in articulating these vibrations.

2021125 4.3 Housing or shaft measurements The vibrations of a gear unit can be measured in two ways, i.e. on the housing (casing) or relative to the shafts. Housing vibration measurements are preferred for gear units operating with rolling element bearings when the clearance in such bearings is small and little relative movement normally occurs

2014318 This technical article explains the concepts and methods of machinery vibration limits and dynamic structural response, with examples and case studies. It covers the sources and effects of vibration, the standards and criteria for acceptable levels, and the techniques and tools for analysis and design. The article is intended for engineers and

201924 Vibration measurement is an effective, non-intrusive method to monitor machine condition during start-ups, shutdowns and normal operation. Vibration analysis is used primarily on rotating equipment such as steam and gas turbines, pumps, motors, compressors, stone machines, rolling mills, machine tools and gearboxes. Vibration

202154 A measure of the quality of the relationship between a system or component input signal and the measured output signal. Coherence is used to judge the accuracy of a transfer function measurement by comparing the input and output signals. Coherence is a number between 0 and 1, with 1 representing the absolute relationship between two events.

2023220 The operation of the world’s first multimode continuous casting and rolling F3 (3rd finishing mill stand) finishing mill was hampered by frequent vibrations. Mill vibrations were found to be caused by the transmission and coupling of vibration energy flow. In this study, an overall finite element model of the F3 stand is established based on the

Generally, vibrations occur when an object moves repetitively in a certain direction but at an equilibrium point. However, talking about the units of measurement, vibration is generally expressed by the units of Frequency, Velocity, Acceleration and Displacement which are denoted by letters f, v, a and d. This is also because if we look at it

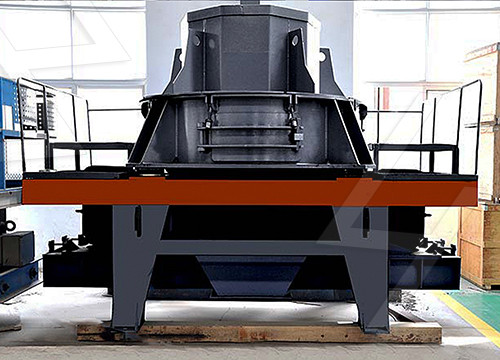

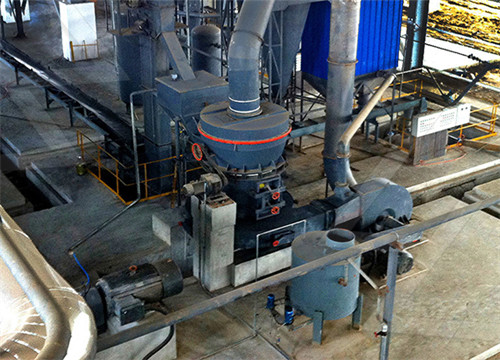

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين