2021111 The variable elliptical vibrating screen (VEVS) adopted the simple biaxial unbalanced excitation system, which helps to realize the equal-thickness screening by adjusting the vibration intensity on each area of the screen surface.

2018315 Aiming at the structural damage of a large vibrating screen caused by large-scale coal-screening, structural vibration and strain signal of a vibrating screen

201941 The screening performance and mechanical reliability of a vibrating screen depends on the kinetic properties according to the law of coal-screening principle, the

A new vibrating screen was developed with a circular mode of vibration for dry screening of moist coal of size fraction −3 + 1 mm. Screen mesh of 2 mm aperture size will be used to

Bharath Kumar Shanmugam. In this , coal screening in vibrating screen was carried out with the size ranges of −6 mm + 4 mm, −4 mm + 2 mm, and −2 mm + 0.5 mm. The

2020914 Abstract. Screening techniques have been widely deployed in industrial production for the size-separation of granular materials such as coal. The elliptical vibrating screen has been regarded as an

2018315 Screening is an indispensable unit operation in coal preparation. Coals often cause structural damage of a large vibrating screen during large-scale screening

201941 Large vibrating screen is the key equipment to improve the clean and efficient utilization of coal. In recent years, various advanced design techniques and

202329 ABSTRACT. Screening is used extensively for the size classification of coals. During the screening process, the impact of oversized material often causes

2019418 For industrial utilization, the coal has to undergo beneficiation. This leads to the production of coal with less ash content (Wang et al. 2019). Coal with less ash content can also be...

2015111 In this , the application of SVM theory in nonparametric modeling of vibrating screen provides the objective function for parameter optimization. On the other hand, the popular artificial intelligence method Particle Swarm Optimization algorithm, was inspired by group behaviors of birds, and was further developed by American electrical

2023315 A review on the advanced design techniques and methods of vibrating screen for coal preparation. Powder Technol. (2019) Collaborative optimization of linear vibrating screen screening efficiency and dynamic response stability based on coupled DEM-MBK simulation. Particuology, Volume 78, 2023, pp. 49-61.

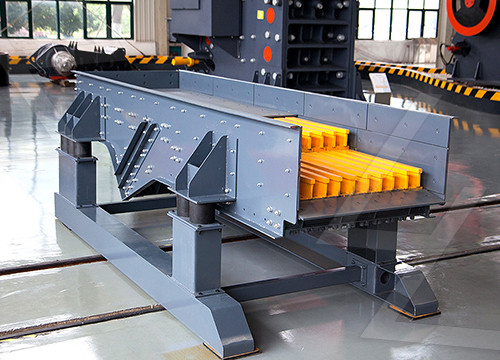

2021101 The structure of a real vibrating screen is particularly complicated and mainly comprises a screen box, screen mesh, and vibration exciters. A simplified three-dimensional model of the vibrating screen, shown in Fig. 1, is established to reduce the complexity but realize the actual screening effect.Additionally, the sieving process in the

201941 For the clean and efficient utilization of coal, coal preparation is an important measure to solve the problem of air pollutant emissions, solid waste generation and save coal resources in the world [1, 2].Screening is the basic process for cleaning and efficient utilization of coal, and is mainly realized via vibrating screen [3].A conventional large

200991 Abstract. The reliability is a key factor for the design and manufacture of large vibrating screen. In the , we presented a new large vibrating screen with hyperstatic net-beam structure. Dynamic characteristic of the vibrating screen was researched and dynamic simulation method of large screening machines was explored.

2017101 The RVS design relates to a new improved vibrating screen for use in screening materials such as bulk granular and particulate materials. The RVS uses a simple theory of reconfigurability to increase its capacity therefore at the same time enhancing the productivity of the machine. Kinematic dynamic analysis of large coal vibrating screen

202341 Flip-flow vibrating screens (FFVSs) are the critical screening equipment for classifying and dewatering wet materials in mining processing industry. During the screening process, the FFVSs can be regarded as a complex rigid-flexible coupled multi-body system where the screening operation and the dynamics of two screen frames interact.

2018620 Screening is an indispensable unit process in coal beneficiation and it is used extensively for the separation of coal particulates. It is the oldest yet most important unit operation for coal processing (Noble and Luttrell, 2015). Vibrating screen is the key screening equipment in coal preparation and its effective utilization.

2017415 The production quality and the processing capacity of vibrating screen were measured by the screening efficiency and the screening time, respectively. The sieving parameters including the length of semi-major axis, the length ratio of two semi-axes, the vibration frequency, the inclination angle, the vibration direction angle and the motion

2020914 Screening techniques have been widely deployed in industrial production for the size-separation of granular materials such as coal. The elliptical vibrating screen has been regarded as an excellent

201711 Kinematics characteristics of the vibrating screen with rigid-flexible screen rod and the behavior of moist coal particles during the dry deep screening process Powder Technology, Volume 319, 2017, pp. 92-101

The present study involves the analysis of the screening performance of the new vibrating screen with the coal feed of varying moisture content of 4%, 6% and 8%. The maximum screening efficiencies obtained for screening the coal feed with the moisture contents of 4%, 6% and 8% were 85.96%, 77.84%, and 68.27%, respectively.

2021315 A vibrating flip-flow screen (VFFS) with elastic sieve mats has been widely used for screening fine-grained minerals due to its good performance. The stability of the VFFŚs dynamic response largely affects its screening efficiency and processing capacity, however, it has rarely been investigated in detail. In this , aiming at reducing the

202391 Section snip Dynamic modelling of the FFVS. The FFVS is a complex rigid-flexible coupled vibrating system. The screening process of the FFVS not only involves the high-frequency flexural motion of the polyurethane elastic screen panels, but also contains the loosening, delamination, and permeation of the processed materials during

2021102 A vibrating screen is widely used in raw coal screening, but intensive resonance in the startup and shutdown stages shortens the service life of the vibrating screen and generates vibration damage to surrounding buildings. Therefore, we designed a novel vibration isolator based on a magnetorheological damper, aiming to improve the

202321 Vibrating flip-flow screens (VFFS) with stretchable polyurethane sieve mats have been widely used in screening fine-grained materials in recent years. In this work, the discrete element method (DEM) is used to study the screening process in VFFS to explain particle flow and separation behavior at the particle scale. Unlike traditional vibrating

202181 Screening is an effective way to realize clean coal, and vibrating screens represent a crucial technology in the screening operation, which is widely adopted in classification, desliming, dehydration, and sculping of raw coal [5], [6]. A vibrating screen is mainly composed of a screen body, an excitation system, and a vibration isolation system

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين