2020331 This study investigates the reprocessing of once disposed tin tailings from a historic German tin operation through different surface

2 Tin ore beneficiation process. Tin (Cassiterite) ore density is larger than the paragenetic mineral, so the tin (cassiterite) ore processing mainly applies gravity separation. Usually, tin minerals also contain

mineral processing technologies has allowed a new insight into the beneficiation of complex skarn ores, enabling commercially viable beneficiation. Therefore, a pilot plant was set

20191122 PDF A presentation about the results of the pilot test campaign for the beneficiation of a complex tin bearing skarn ore. The shown results are based Find,

2023227 In the past two decades, tin reserves in China have experienced a rapid decline because of active mining activities; simultaneously, cassiterite beneficiation has

2019925 In short, the beneficiation method of tin ore has broken through the traditional gravity separation process and entered a new period of combined use of several beneficiation methods. Nevertheless, gravity

Ore Beneficiation Process As one of the leaders of mineral processing industry in the world, Xinhai firstly gained Class-A design qualification, and possessed mine design institute

201511 The influence of particle size on gravity concentration and flotation techniques is revisited, and surfactants in cassiterite flotation are thoroughly reviewed.

2021124 The focus of the study is the role of the beneficiation in the production of metals and minerals in terms of environmental impacts, with a focus on the flotation

202191 Tantalum-tin containing mineral is one of the highly valuable and unexploited mineral resources in Africa, but lack of technology for exploration,

20231020 The gravity separation of hematite mainly includes jig beneficiation of coarse-grained hematite, centrifugal beneficiation of fine-grained hematite, and spiral beneficiation and shaking table for medium-grained hematite. Jig separator. shaking table. 4. Roasting Magnetic Separation.

20231020 Bauxite flotation process plant. 1. The mined bauxite mixture is screened through a single-layer or multi-layer screen surface by a vibrating screen; 2. Preliminary crushing of the screened aluminum ore

2016524 The flowsheet below Explains the Extraction of Tin Ore as shown by a study adapted to the concentration of a lode tin deposit.Cassiterite (SnO2) is very friable and special considerations to

20231020 For example, choose the chlorination method and the reduction rust method. 3. Vanadium-bearing carbonaceous slate. Vanadium-bearing carbonaceous slate. Sedimentary vanadium-bearing carbonaceous slate is also an important type of vanadium ore resources in my country, and it is still in the research stage. Vanadium in the ore

202131 Abstract Beneficiation of low-grade ore is of critical importance in order to meet the growing demand for coal and mineral industries. But, low-grade ores require fine grinding to obtain the desired liberation of valuable minerals. As a result, production of fine particles makes the beneficiation process difficult through conventional gravity

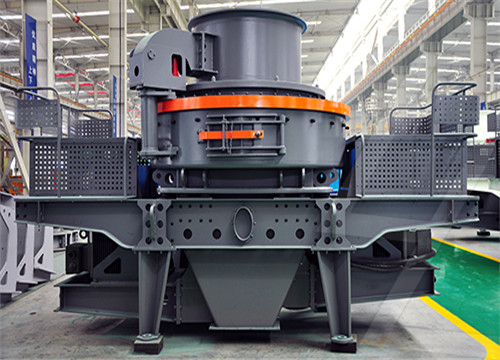

20231020 The copper ore beneficiation plant uses three processes: crushing, grinding and beneficiation. It’s just that the selection of individual copper ore processing equipment and beneficiation technology will be slightly different. Among them, in the crushing process, the use of three-stage closed-circuit crushing can well complete the

20231020 Dry beneficiation is generally used to process bentonite with better raw ore quality, or bentonite-rich ore with montmorillonite content of more than 80%.This method is to dry the raw ore in the sun, air dry it naturally or dry it in the oven. It is first crushed manually or with a jaw crusher, and then crushed with a Raymond mill and other roll mills

2022111 For placer tin ore with a low monomer dissociation degree, it often needs to go through two gravity processes: screening jig, rod mill jig dehydration;. Tin processing of gravity separation is based on the principle of gravity beneficiation, and the separation is carried out according to the specific gravity difference between

2023927 In addition, one of our tin beneficiation plant customers has a beneficiation process that firstly crushes the raw ore to -20mm, then sieves it into two grades of 20-4mm and 4-0mm, and 20-4mm enters the heavy medium cyclone for pre-selection. After a stage of rod grinding, the heavy products of the heavy medium cyclone are pre-selected by

202311 Cost structure for the chromite ore beneficiation plant. The economics of any mineral-processing plant depends on the economics of the mineral under separation, which can be ascertained using the below thumb rule mineral value per ton is greater than processing costs per ton. 3.8.1. Processing cost

20231020 But heavy medium beneficiation or heavy liquid beneficiation is an effective method for spodumene beneficiation. For example, the mineral processing staff of the United States Bureau of Mines also used tetrabromoethane as the heavy liquid (density 2.9529 g/cm3) to carry out a continuous test of the heavy liquid cyclone separation of

202155 The final concentrate contains 46% tantalum niobium and 5-6% tin, and the recovery rate is 86%. We also use this beneficiation process of tantalum niobium tin ore for our Rwanda customers, 51% tantalum

Xi'an Desen Mining Machinery Equipment Co.,Ltd: Find professional tin beneficiation plant, coltan ore processing, portable gold trommel, carbon in pulp and CIP/CIL machine manufacturers and suppliers in China here. We export bulk high quality portable products to Tanzania and many other countries. For price consultation, contact our factory.

202028 Cliff’s Tilden plant in Cleveland, USA, is the only iron ore beneficiation plant, where selective flocculation technique, using degraded starch as the flocculant, has been applied to produce pellet grade concentrate from a feed containing around 32% Fe . The plant has a capacity of processing 10 million tons and is in operation since 1975.

201511 Turner and Hallewell (1993) described in detail the Wheal Jane tin beneficiation plant flowsheet and process developments undertaken while improving the product grade and recovery. Wheal Jane plant was treating about 180,000 tonnes per annum of cassiterite ore and was producing 57–60% Sn in the concentrate with 82% tin

2023104 1. Gravity separation. The process has the advantages of simple equipment, good stability, no beneficiation agent, low cost, and less environmental pollution.The barite gravity separation method is mainly based on the density difference between barite and associated minerals. Including ore washing, screening, desliming, jig

201511 Gravity concentration is an age-old method used in the mineral processing plants for the separation of heavy and light mineral particles. Importance of this technique has been reduced due to the invention of flotation (Burt, 2000), which is more efficient and applicable to a wide variety of ore minerals.

20231030 Magnetite beneficiation Process. 1. Single Magnetite: Most of the iron minerals in a single magnetite ore are magnetite. The ore composition is simple, and the weak magnetic separation process is often used: When the grinding particle size is more than 0.2mm, most iron ore magnetic separation plants often adopt a one-stage grinding

20231020 Gold placer mining processing flow. Gold placer mining consists of three major operational steps: extraction, beneficiation and processing. Extraction is defined as removing ore material from a deposit and encompasses all activities prior to beneficiation. Beneficiation is the operation by which gold particles are separated from the associated

20191110 LCA was performed on the lead-zinc ore mining and beneficiation. • Processing plant can bring the more serious pollution than other subsystems. • Pollution from tailings and chemical production should be controlled as a priority. • Secondary metal production and clean energy need to be developed in China.

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين