2023831 It can be seen that the profit margin of artificial sand is very large. Artificial sand production process The production process of artificial sand and gravel aggregate can generally be divided into the following stages: raw materials → coarse crushing → fine

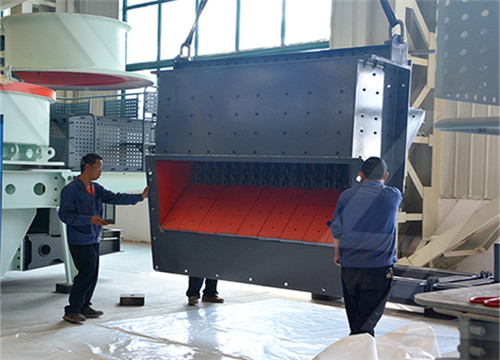

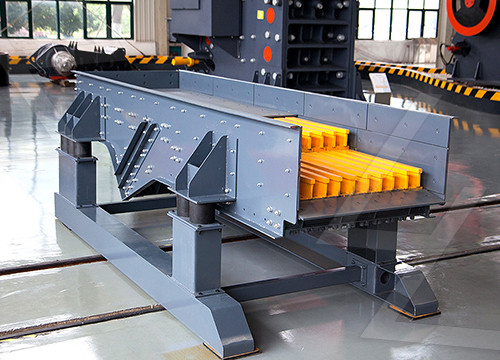

202186 The equipment configuration of a sandstone sand making production line with an hourly output of 60-80 tons is: silo + vibrating feeder + jaw crusher + impact

202395 There are two ways of vertical axis breaking sand production: open circuit production and closed-circuit production. Each way can be divided into dry process, wet

2022104 Factors such as technology, equipment, transportation, environmental protection, and type of parent rock should be considered in the production of MS. The

2014530 Artificial Sand production is several times after the stone was broken rock particles having diameters of less than 4.75mm, the rough broken, broken generally were

2020210 1. Material The hardness, viscosity and humidity of material could affect artificial sand output. Greater hardness, higher viscosity and higher water content, the output is lesser. 2. Operation and

201293 The following is the third generation maker which is truly suitable for the production of artificial sand: The application of the third generation sand make machine

2020528 Artificial Sand cuts costs and enhances production of manufactured sand with Life Cycle Services. Artificial Sand’s decision to venture into the production of

2020116 The EU-funded SMARTSAND project developed Lypors™, an advanced engineered, artificial sand material manufactured from fly ash for use in the construction

2023224 Due to the high price of river sand, its shortage and unsustainable extraction from the environment, artificial sand (AS) has been promoted as a fine aggregate for producing concrete.

202323 A certain amount of stone powder is produced in the process of sand production, which is one of the most obvious differences between artificial sand and natural sand. The definition of stone powder

202151 The production of sand from crushed stone (artificial sand) has been conducted for over a decade using vertical shaft impact (VSI) crushers or rotor impact mills. These machines consist of a rotor revolving at high speed that throws centrifugally the material into the crushing chamber, where the comminution occurs by rock-on-rock

201293 In the mining industry, this product is widely used in the preceding grinding process, it can produce large amounts of iron ore fines, reduce the high cost of grinding load. As the excellent low wear characteristics of this sand maker,this series device is also used for high abrasive and secondary disintegration crushing production.

2014111 The sand production data of 23 problematic wells of North Adriatic Sea was used to establish the predictive models. These data have been previously used by Kanj and Abousleiman (1999) to develop a BP-ANN model for prediction of sand production onset. Aforementioned intelligent approach is extended in the present stone by

2020116 An ever-growing population and a continuing trend towards urbanisation mean that around 40 billion tonnes of sand are mined each year to meet the world’s increasing demand for construction materials. Because sand from the desert is unsuitable as a building material, it must be mined or dredged from rivers, deltas, and coastal and

202271 However, the oil production is difficult to control and the oil production rate is low, so the related supporting technologies still need to be improved to optimize the single horizontal well SAGD. In general, the optimization of well pattern to enlarge the steam chamber is one of the key points of future research for thin-layer super-heavy oil

2023613 In order to improve the reuse of solid waste generated in construction production, artificial aggregates consisting of 100% by weight of construction solid waste, including concrete slurry waste (CSW) and waste brick masonry powder (WBMP), were produced. and effectively reduces the consumption of non-renewable resources such

202031 Sand production is worldwide problem. It always has significant consequences on field development. Sand production from unconsolidated formation reservoir is a very challenging issue as it ends the production life of a reservoir and well. In the oil and gas industry, millions of dollars are spent yearly for the cleaning of sand.

202186 Granite sand processing plant configuration: The equipment configuration of a granite sand making production line with an hourly output of 80-130 tons is: feeder + jaw crushers + vibrating screen + conical crusher + sand making machine + fine sand recycling machine + belt conveyor. 3. Quartzite sand processing plant.

201573 A ternary sand mixture made using 70% dune sand (DS) and 30% slag sand (SS) and brick sand (BS) combined. Five series of ternary aggregate mixtures and one reference control mixture (100% DS) prepared. The physical properties of natural and artificial sands were determined according to analysis results.

2021113 Manufactured sand (M-Sand) is artificial sand produced from crushing hard stones into small sand sized particles Knowledge and b2b portal for construction and infrastructure Constro facilitator. Monday,

2021817 Effect of illegal fishing on artificial reef. The model showed that, in the absence of illegal fishing, there was an optimum volume of ARs to maximize catch in ARs with both production and

2020210 Otherwise, the final sand production rate will definitely fail. Always, the user should consider their own production situation when buying sand plant equipment. Artificial Sand vs Natural Sand. Artificial sand is

2022225 1. Cobblestone sand production line Pebble Features. The main component of cobblestone is silicon dioxide, which has the advantages of non-toxic, tasteless, strong corrosion resistance, hard quality, and strong pressure resistance. It is the main material for the production of artificial sand and stone, and it is also green building

2021827 One of the most applied artificial lift methods is sucker rod pump. Sucker rod pumps are considered a well-established technology in the oil and gas industry and thus are easy to apply, very common worldwide, and low in capital and operational costs. Cope with the sand production by altering the production equipment to withstand sand

202221 Considering the above-mentioned concerns, turning unutilized wastes into artificial aggregates for use in concrete has become a worthy topic. Currently, the common manufacturing methods of artificial aggregates include cold bonding and sintering (Bijen, 1986).The cold bonding method typically utilizes cementitious materials (such as cement

2022711 In the production of artificial sand, the output of artificial sand is related to many factors. For example: the hardness of the material, the humidity, the fineness of the finished sand, the maintenance and quality of the equipment itself, etc. 1. The different fineness of finished sand .

20221114 Sand production can plug tubing, casing, flowlines and surface vessels. There is a large assortment of devices available for downhole sand exclusion, inflow management, production equipment, artificial lift, surface separation, and disposal. Decisions around sand production are not purely economic. Regulatory and

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين