201611 Abstract. This chapter deals with the designs and operation of different

Double roll crusher DRC throughput Oversized lumps 1. Introduction Comminution

2022821 The share of produced energy spent on crushing is more than 5% in the

2022329 Analysis of the designs of roll crushers and mills for the disintegration of

20211211 minimum roll gap between the rollers. Displacement of two control

20181025 PDF An improved approach is presented to model the product

20181025 An improved approach is presented to model the product particle size distribution resulting from grinding in high-pressure roll crusher with the aim to be used in standard high-pressure grinding rolls (HPGR).

201741 Double roll crushers (DRC) have the highest throughputs among primary

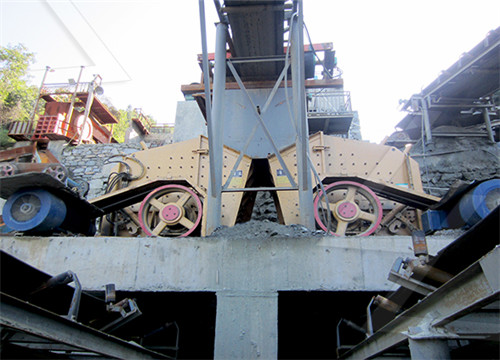

crusher chamber. In this , by analyzing the crusher mechanism of double toothed

2023516 Over the last few decades, the demand for energy-efficient mineral-processing methods has continued. The necessity to develop energy-efficient technologies for the mineral industry will increase in the future, considering the exhaustion of high-quality resources and severe environmental limitations. The subject of this study is crushing

20211022 The capacity of the jaw crusher available in the laboratory is 725 t/h. Jaw crushers range in size. up to 1680 mm gape by 2130 mm width. This size machine will handle ore with a maximum size. of 1.22 m at a crushing rate of approximately 725th -~ with a 203mm set. However, at crushing.

Roll Crushers. In Mineral Processing Design and Operations (Second Edition), 2016. 6.2.3 Roll crusher circuit design. Roll crushers are generally not used as primary crushers for hard ores. Even for softer ores, such as chalcocite and chalcopyrite, they have been used as secondary crushers. Choke feeding is not advisable as it tends to produce particles of

2015423 8.DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1.this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc. 2.the adjustment of the particle size: between the two rollers equipped with adjustment device like pads or

The roll crusher consists of a pair of horizontal cylindrical manganese steel spring rolls (Fig. 13.14), which rotate in opposite directions. The falling feed material is squeezed and crushed between the rollers. The final product passes through the discharge point. This type of crusher is used in secondary or tertiary crushing applications.

For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm. The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6. Settings and Damping Group 7. Hydraulic Cylinder 8. Toggle Plate 9. Swing Jaw 10.

20181119 Single roll crusher and double roll crusher (Wills, 2006). In double roll crushe r, there are two rollers in which one is fixed, and another is attached to sprin g. Both rollers are kept facing

2023923 2.1.5 Thickness of the RollFigure 1 is the geometry of a double roll crusher with a spherical particle about to enter the crushing zone of a roll crusher and is about to be nipped [4], [5]. For rolls that have equal radii and length, tangents drawn at the point of contact of the particle and the two rolls meet to form the nip angle

The diameters of the light duty crushers vary between 228 and 760 mm with face lengths between 250 and 460 mm. The spring pressure for light duty rolls varies between 1.1 and 5.6 kg/m. The heavy duty crusher diameters range between 900 and 1000 mm with face length between 300 and 610 mm.

2019111 A discrete element method (DEM) model of the crushing process of a toothed double-roll crusher (TDRC) is established using the bonded particle model. DEM results and experimental data are compared quantitatively and a relatively good agreement is observed. The effects of rotation speed and structure of crushing rolls on the

201931 The crusher was then retrofitted with hydraulic cylinders to increase the pressure between the rollers. This was the predecessor to the high-pressure grinding rolls (HPGR) crusher, which became popular in Europe for applications in the cement industry. The introduction of the HPGR in minerals processing sparked at the beginning of the 2000s.

2022821 The design has been developed for a single-roll crusher with the forced supply of destroyed material into the crushing zone [].The capture of a crushed piece occurs due to the stop located on the roll (see Fig. 1); in this case, the condition for formation of a complex stress state in the crushed piece is observed, and the energy consumption is

20211211 Abstract. Roller crusher is widely used in solid and block material pulverizing. Roll gap between the rollers is usually adjusted to satisfy the particle size of output material. In order to realize convenient adjustment, a roll gap control scheme based on electro-hydraulic technology is designed and optimized.

2019111 A toothed double-roll crusher (referred to hereafter as TDRC) consists of a pair of oppositely rotating rolls, which have a series of intermeshing teeth protruding from the roll surfaces. The crushing action of TDRC is a combination of compression and ripping, where the teeth can dig into the rock and larger pieces than the roll diameter can be

2018117 Double roll crushers (DRC) have the highest throughputs among primary crushers. In the oil sands, the hourly capacity may exceed 14,000 t/h. They are preferably used to comminute medium-hard rock

Contact us today to discuss your primary crusher application with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher, or locate an agent near you. Contact Us. Williams Crusher designs and manufactures a variety of Roll Crushers that provide efficiency and durability.

20171121 rolls using the discrete element method Paper F: Calibration of DEM Contact Models Paper G: Cone Crusher modelling and simulation using DEM Paper H: Cone crusher performance evaluation using DEM simulations and laboratory experiments for model validation

2017216 The formula used to calculate feed rate is shown below. 𝑄 = 60𝜋𝐷𝐿𝑊𝜔𝜌 𝑏(ton/h) Calculation of double roll crusher efficiency The efficiency of the double roll crusher can be calculated by taking the ratio of surface energy crated to the energy absorb by the substance the formula is shown below: 𝜂 𝑐

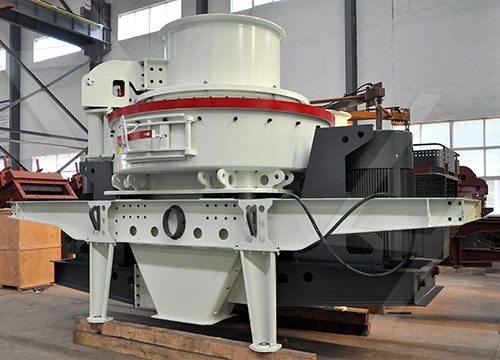

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين