202192 Compare of J aw Crusher and Gyratory Crusher. To Wrap Up. There are many types of crushers in mining, mainly jaw crushers, gyratory crushers, impact

A mining primary jaw gyratory crusher for large, coarse materials . The main benefit of the Jaw Gyratory Crusher Pro is its ability to crush bigger chunks of material at high

The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 1.5 m (for the largest equipment). This crusher can handle products with a Mohs hardness that is not

2016228 The jaw crusher will handle sticky,’or dirty feed better than the gyratory, there being no diaphragm below the crushing chamber on

2012729 A Jaw Crusher reduces large rocks by dropping them into a flat “V” shaped space created between a fixed surface and a movable surface. The compression is

20221121 Jaw gyratory crushers design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is

2015718 Gyratory CrusherJaw Crusher Compared. There is another comparison that should be taken into consideration, that is the amount of space that each takes. The Jaw crusher is the smaller of the

1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed side settings, 3. options on feeding method, e.g., intermittent feeding (manual

201751 In a comminution plant where the reduction of rock material or ore sizes is desired, two machines are commonly used for primary crushing: the jaw crusher and the

They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impact. A jaw crusher consists essentially

20191210 gyratory crusher working principle animation. image credit by 911 Metallurgist. Similar to a jaw crusher, the gyratory crusher pulverizers the stones by placing them between two manganese steel plates and

The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 1.5 m (for the largest equipment). This crusher can handle products with a Mohs hardness that is not necessarily less than 5. As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concaves.

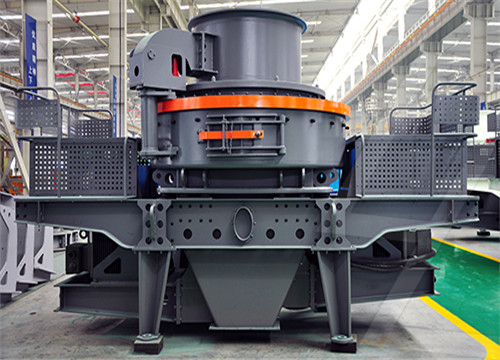

2023527 The overall structure of the machine. From the perspective of the overall structure, the cone crusher is 1.7-2 times heavier and 2-3 times higher than the jaw crusher with the same feeding opening size. A Larger machine means

202192 2) Features. a. The structure is simple, the worn parts and the liner are easy to replace, and it is easy to take care of and repair. b. The force on the upper part of the movable tooth plate increases with the proximity to the fixed tooth plate. The greater the obtuse angle formed by the thrust plate, the greater the force.

2023216 A gyratory crusher works by rotating a mantle within a concave bowl, while a cone crusher works by compressing material between a mantle and an outer bowl. Another difference is that gyratory crushers are typically used in larger-scale industrial applications, while cone crushers are used in smaller-scale applications such as

Cross section of a Kleeman primary jaw crusher Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone. The ore is discharged through the smaller

2022513 Primary crusher Jaw crusher Expt. + Nume FEM analysis can be used as a powerful tool for analyzing the failure of the component in jaw crusher 2013 Rusi´ nski et al. [16] Poland 3 Primary crusher Jaw crusher Expt. + Nume Regression analysis was done in order to find out the effect of mechanical properties ofrock onthespecific power

2023223 In terms of design and construction, gyratory crushers and cone crushers have distinct differences. A gyratory crusher has a mantle that rotates within a concave bowl, while a cone crusher has a mantle that rotates within a bowl-shaped concave. This design allows for a larger feed size and a higher capacity for both types of crushers, but

2022920 The plate dimensions of the un-optimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig. 3.The load and boundary conditions for the static structural analysis were as shown in Fig. 4.Design of Experiments (DoE) was then conducted where the minimum and maximum values of the target parameters were

2020117 The Basic Difference Between a Gyratory and Jaw Crushers are: 36 37. ii) Cone Crusher 37 Cone crusher 38. ii) Cone Crusher 38 Mantle (movable cone) and concave (fixed cone) VPE-mobile-jaw-crusher-plant-700x394 Jaw Mobile Crushing Station • Application: Sand quarry, mining, coal mining, concrete mixing station, dry mortar,

2020214 Jaw crusher mempunyai keunggulan struktur sederhana, kinerja stabil, perawatan mudah, menghasilkan partikel akhir dan rasio penghancuran tinggi. Jadi jaw crusher merupakan salah satu mesin penghancuran paling penting dalam lini produksi penghancuran batu. Secara umum mesin Crusher dapat digunakan untuk mengurangi

201751 Abstract. In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al., 2015). Approaches to date have been mainly property specific.

2014129 18.• Single Toggle Jaw Crusher • In the single toggle jaw crushers, the swing jaw is suspended on the eccentric shaft which leads to a much more compact design than that of the double toggle jaw crusher. •

20201024 The jaw crusher is an intermittent crushing operation, so the productivity is relatively low, impact vibration, energy consumption will be higher, and the product size is not as neat as the

2022919 Gyratory crushers are better at crushing large boulders while cone crushers are better at handling smaller rocks. Cone crushers are more affordable. Gyratory crushers tend to be more expensive but can crush more material in a single pass. Cone crushers are less expensive and require more passes to achieve the same level of crushing.

2023227 A jaw crusher is a primary crusher used in crushing processes that involve large pieces of material. It is designed to reduce the size of the material for further processing or use. Jaw crushers are typically used in the mining, construction, and demolition industries. The jaw crusher has a fixed jaw and a moving jaw.

The gyratory crusher has no rival in large plants with capacities starting from 1200 t/h and above. To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier. Also, primary gyratories require quite a massive foundation. Primary crushing with impact crushers

2021325 The jaw crusher is more widely used, which may be because of price factors. Besides, there are big differences between the two in terms of appearance structure, production capacity, process design, energy consumption, maintenance, etc. The differences between them will be analyzed in detail below. Comparison of advantages

قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين